Included in Applied Technical Services’ extensive list of mechanical testing services is metal fatigue testing. Our lab experts can verify whether metallic components operate in accordance with applicable standards while ensuring safe and reliable operation.

About Fatigue Testing

Metallic components are often subjected to cyclic loading over the course of their service life. These repeated stresses, in conjunction with any one or a combination of other factors, can initiate small cracks which propagate over time. Once they reach a critical size, small cracks can rapidly expand and lead to fatigue failure of the component.

Factors Related to Metal Fatigue Cracking:

- Environmental Factors

- Inadequate Material Properties

- Manufacturing Defects

- Material Defects

- Poor Maintenance

- Product Design Issues

Fatigue testing is a method of materials testing designed to simulate cyclic loads so businesses can gain insight into how their materials withstand such loading in real-world applications. By working with a third-party testing service provider, such as ATS, businesses can get a better idea of how to design, manufacture, or process materials so as to avoid equipment failure, unexpected costs, and safety risk to personnel as a result of failure due to metal fatigue.

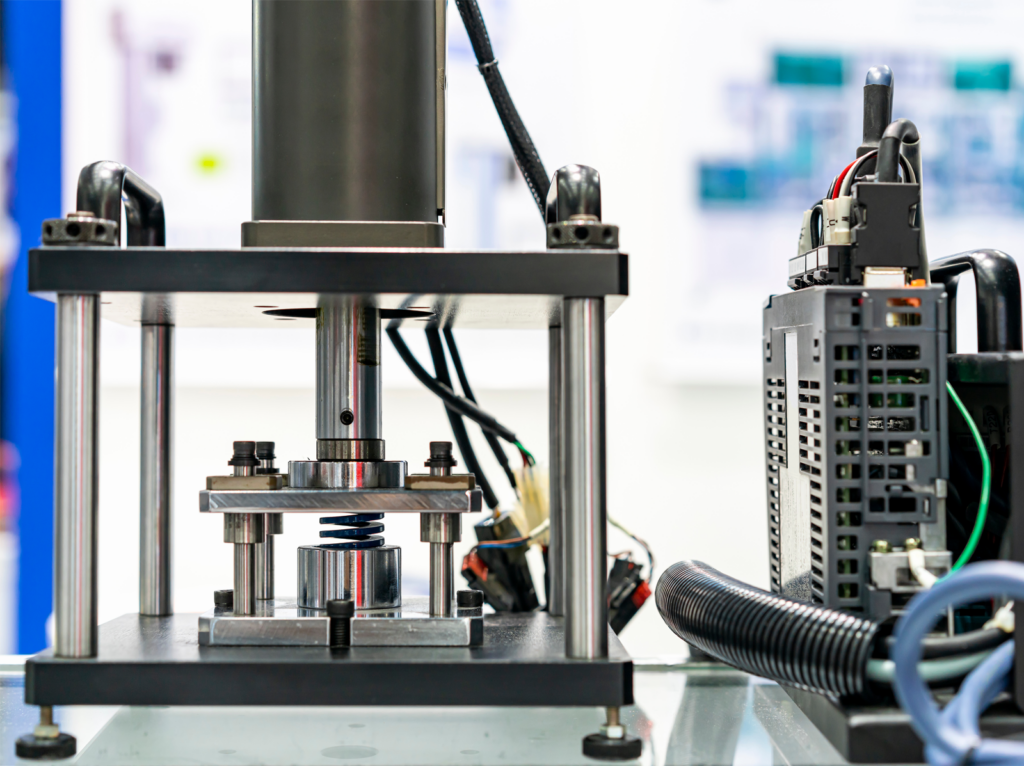

A fatigue test works by subjecting the metal to a repeated loading and unloading force in a specialized fatigue testing machine. ATS’ mechanical testing lab can test to common SAE and ASTM standards as well as fully custom specifications. Additionally, our testing machines have a load capacity of 55 Kip and can test at temperatures up to 1000°C.

Fatigue Testing with ATS

Our services don’t stop at fatigue testing; with over 50 years of experience in assisting clients, Applied Technical Services offers a wide range of testing and inspection services for numerous industries. We also offer metallurgical evaluations, chemical analysis, and failure investigations. To maintain a high level of service quality, each one of our services is backed by our ISO certified quality management program.

Why Our Clients Choose ATS

- Accurate Results

- Assisting Clients Nationally and Internationally

- Detailed Reporting

- Experienced Technicians and Engineers

- Helpful Client Support

- Short Turnaround Windows

We recognize the value of strategically testing metallic materials and equipment. If you are searching for a reputable metal fatigue testing provider, contact us today for a free quote. ATS — We take a closer look.