- Home

- Services/IndustriesServicesindustries

- About Us

- LocationsStatesAccordion ContentAccordion ContentAccordion ContentAccordion Content

- Job Openings

- Quick Links

- ATS Family

The Importance of Solar Exposure Testing

Applied Technical Services performs solar exposure testing to support clients who need to verify whether their materials and components resist the weathering effects of sunlight as appropriate to their final product’s anticipated service conditions. Consumers have long noted how years of sunlight exposure can affect their household products, even if they never consciously drew the connection; the vibrant colors of lawncare tools’ coatings fade, vinyl car interiors crack, and plastic outdoor furniture becomes brittle and loses that glossiness it initially had. The segment of the electromagnetic spectrum that the sun naturally generates — namely infrared (IR), ultraviolet (UV), and visible light waves — weathers materials over time, causing adverse aesthetic and structural changes. The sun’s other characteristic emission, heat, also prematurely ages plastic products.

It makes sense that sunlight would cause changes in inorganic materials over long periods of exposure, given that the scientific community has established a link between skin cancer and sustained solar radiation. Enduring other environmental weathering stimuli endemic to outdoor service conditions, specifically temperature variations and humidity, often exacerbates the negative effects of long-term solar exposure. A wide range of materials — e.g., plastics, paints, coatings, and vinyls — affected by these stimuli can incur many types of defects ranging from the structural, such as delamination, embrittlement, and distortion, to the aesthetic, such as chalking and fading colors. Clients send samples to solar simulation testing labs like ATS to help validate their design materials for outdoor use. Our experience performing this method makes us a stellar choice for clients that need to determine how well their materials will hold up in the face of extended sunlight exposure.

About the Method

We help companies make the best versions of their products by verifying that their materials can withstand the degradation Mother Nature is expected to cause when they are placed in service. Using the solar radiation exposure method, our technicians can simulate years of damage incurred from sunlight over the course of weeks or even days. These weathering experts carefully apply precise amounts of radiation to simulate the final product’s anticipated service environment. Doing so allows them to determine whether client samples will perform as required by industry standards, government regulations, and their own internal quality assurance guidelines.

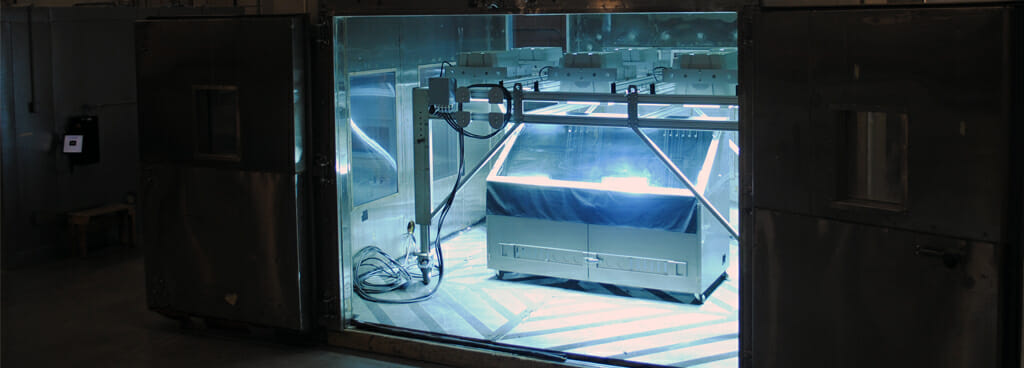

The ATS environmental testing division performs all our solar radiation testing. Their 10’×10’×8’ walk-in chamber allows them to accommodate larger components or even entire assemblies. It can achieve temperatures ranging from as high as 80°C to as low as -40°C and humidity levels from 5% to 95%, allowing our technicians to control most of the environmental factors inherent to outdoor service conditions. Our testing experts regularly perform this test according to DIN 75220, VDA 230-219, MBN 55555-5, and MIL-STD 810G Method 505.5. ATS’ Marietta testing lab, where we perform all solar radiation exposure testing, maintains an ISO 17025 accreditation through the A2LA to perform this method to DIN 75220.

ATS: Trusted Environmental Testing Experts

We at Applied Technical Services take pride in providing testing, consulting engineering, and inspection capabilities of the highest caliber. Our company has grown immensely in the five decades since our founding. In 1967, ATS was a group of three engineers operating out of the founder’s basement. Today, we comprise a multidisciplinary firm employing over 1,000 specialists in an array of fields to serve the varied needs of our esteemed clientele. Our team of technicians, inspectors, chemists, scientists, Professional Engineers, calibrators, trainers, and investigators answer the call when companies across the globe need ATS’ quality services. While we regularly serve many different industries, the following benefit most often from our solar radiation exposure testing capabilities:

- Manufacturing

- Insurance / Legal

- Healthcare / Medical

- Defense / Military

- Consumer Products

- Communications

- Automotive

- Aerospace / Aviation

Dedicated to Quality

ATS’ environmental testing division conducts all solar testing services under our ISO 9001-registered quality assurance program. The Marietta lab initially achieved this certification in 1998 by submitting its business procedures to a thorough auditing process by ISO-approved inspectors, who determined that our system complied with the 9001 standard on effective quality management practices. We have maintained uninterrupted registered status by undergoing the same auditing process periodically for recertification. ATS willingly engages in this exacting process because doing so helps us make improvements to both the quality and scope of our services. We demonstrate respect for our clients by holding ourselves publicly accountable for the quality of our work; it gives them a reason to work with us again in the future.

We uphold the following policies to ensure our clientele enjoys the best customer experience working with ATS:

- Clear, Accurate, Detailed Reporting — Quickly

- Our testing specialists perform methods according to recognized standards and return quality findings in a short turnaround time. By accommodating the client’s schedule, we equip them to make informed and timely decisions regarding the results of their testing.

- Connected to the Right Person, Every Time

- Sometimes clients have questions or need clarification; we retain a team of customer service representatives to act as ambassadors between clients and our technical experts. These customer relationship professionals connect them with the most relevant staff member to help clients move toward resolution.

- Access to Helpful Test Specialists

- Lab personnel remain accessible to clients reaching out with questions about either the status or results of their testing. These experts are responsive to client needs and stay engaged while helping them solve their problem.

If your company needs solar radiation exposure testing from a respected environmental testing and weathering laboratory, contact ATS today for a free quote — We take a closer look!

Request Form

"*" indicates required fields