- Home

- Services/IndustriesServicesindustries

- About Us

- LocationsStatesAccordion ContentAccordion ContentAccordion ContentAccordion Content

- Job Openings

- Quick Links

- ATS Family

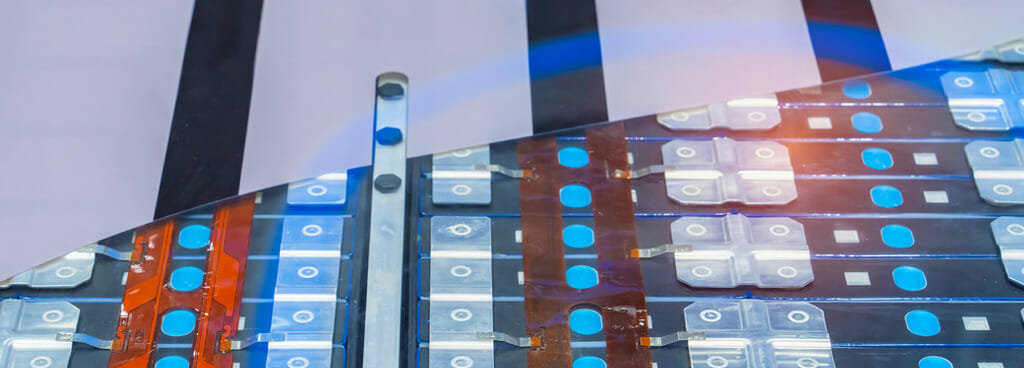

UN 38.3 - Lithium Battery Vibration Testing

The A2LA-accredited environmental testing lab at ATS delivers UN 38.3 lithium battery vibration tests to assess if the products align with UN requirements. Enforced worldwide, UN 38 establishes the criteria for rigorous lithium battery testing methods to ensure safety during transport. A Class 9 hazardous material, lithium products present a risk of explosion, fire, and loss of life if designed or handled improperly.

ATS can test at the cell or pack level to determine if a battery, shipped alone or with its intended product, is safe for air, water, and land transportation. The test anticipates all points in the transportation process, including manufacturing, distribution, and end-use.

The Importance of UN 38

UN 38 is a self-certify standard that requires the manufacturer or distributor to confirm the battery complies with applicable regulations. UN 38.3 is third in a sequence of tests that covers lithium and lithium-ion batteries with UN classifications:

- UN 3090

- UN 3480

- UN 3091

- UN 3481

Manufacturers and distributors risk a recall, loss of reputation, and liability if their product does not meet the test sequence’s safety requirements. To ensure their product’s quality and safety, clients secure the services of independent third-party labs, such as the ATS environmental testing lab.

UN 38.3 Procedure

The ATS environmental testing lab performs extensive lithium battery vibration testing procedures in accordance with UN 38.3. Our state-of-the-art electrodynamic vibration system simulates common transportation frequencies to anticipate a battery’s reactions to real-life conditions.

During the vibration testing procedure, we subject the battery to a logarithmic sweep between 7 Hz and 200 Hz in 15-minute cycles over three hours. We can repeat the test in all three mutually perpendicular mounting positions.

Vibration Testing Outcomes

UN 38.3 is a pass/fail test. If the battery passes the vibration test intact, the manufacturer can proceed with T.4 (shock testing). If the battery fails, ATS can return the battery to the manufacturer for redesign and retesting.

To pass, the battery must reach 200 Hz frequency without failure, defined as any of the following:

- >10% drop in open circuit voltage (unless tested at a fully discharged state)

- Explosion or disassembly

- Fire

- Leakage

- Mass loss

- Rupture

- Venting

Our experts measure the battery’s mass and voltage before and after testing to identify indications of mechanical failure or compromised functionality. ATS’ NDT experts use a range of nondestructive testing and inspection methods, such as Computed Tomography (CT), to identify microscopic faults and damage. Regardless of whether a battery passes or fails vibration testing, our experts provide a thorough and comprehensive analysis to aid clients in their next steps.

Testing with ATS

ATS supports national and international industries with a wide range of consulting engineering, calibrations, inspections, and testing services. Founded in 1967, we now lead a growing Family of Companies to reach clients throughout the country and abroad. Our qualified labs deliver high-quality services with a quick turnaround rate, helping clients to minimize downtime and get their products on the market faster.

Known for our exceptional customer service, we qualify for multiple quality standards and industry certifications:

- ISO 9001:2015 - Quality Management System

- (A2LA) ISO/IEC 17025:2017 - Calibrations and Mechanical, Chemical, Electrical, and Nondestructive Testing

- FAA Repair Station

- CPSC-Approved Lab

Click here to read more about our certifications.

Contact Us

Call +1 (888) 287-5227 or complete the request form on this page to schedule UN 38.3 vibration testing. We are qualified to evaluate various battery types and materials under extreme temperatures, pressures, and shock. Check out our complete list of battery testing capabilities or call us to learn how ATS can support your business needs.

Request Form

"*" indicates required fields

Battery Testing Links

- Abuse Testing Lithium Ion Batteries

- Battery Abuse Testing

- Battery Chemical Analysis

- Battery Durability Testing

- Battery Electrical Testing

- Battery Impact Testing

- Battery Management Systems BMS Testing and Certification

- Battery Performance Testing

- Battery Safety and Certification Testing

- Battery UL Certification

- Battery Vibration Testing

- Chemical Testing EV Batteries

- Electrical Testing EV Batteries

- Electrical Vehicle Battery Testing

- E Mobility Battery Testing

- Energy Storage System ESS Testing and Certification

- E Scooter Battery Testing

- EV Battery Testing Lab

- EV Battery Mechanical Testing

- EV Battery Pack Vibration

- EV Battery Thermal Testing

- High and Low Temperature Testing EV Battery

- Hoverboard Battery Testing

- IEC 60896-21 Stationary Valve-Regulated Lead-Acid Batteries

- IEC 61427 Secondary Cells and Batteries for Photovoltaic Energy Systems Testing

- IEC 62133 Lithium Battery Safety Testing and Certification

- IEC 62133-2 Lithium Ion Battery Testing Certification

- IEC 62619 Secondary Cells and Batteries Containing Alkaline Testing

- Lead Acid Battery Testing

- Mechanical Testing EV Batteries

- Micro Mobility Battery Testing

- PNNL 22010 ESS Performance Testing

- RESS Safety and Abuse Testing

- RTCA/DO-311 Performance Testing Lithium Batteries

- SAE J1798 Performance Rating of EV Battery Modules Testing

- SAE J2185 Life Testing Heavy-Duty Storage Batteries

- Telcordia GR Battery Testing

- Thermal Testing EV Batteries

- UL 1642

- UL Battery Certification

- UL 1973 Battery Testing

- UL 1989 Standby Battery Testing and Certification

- UL 2054

- UL 2271 E Bike Battery Testing and Certification

- UL 2580 Electric Vehicle Battery Testing and Certification

- UL 9540A

- UL 9540 Thermal Runaway In ESS Testing and Certification

- UN 38.3 Testing

- USABC Battery Testing

- Verizon VZ.TPR Battery Testing