The Applied Technical Services Family of Companies performs lubricating oil analysis to evaluate oil quality and analyze equipment conditions.

Analyzing Lubricant Oil

Lubricating oil analysis is a diagnostic technique used as a part of predictive maintenance, assessing the condition of lubricants in machinery and equipment to ensure optimal performance and efficiency. This analysis method involves examining samples of lubricating oil to identify wear particles, contaminants, and signs of degradation that can affect the health and longevity of mechanical systems.

The primary goal of lubricating oil analysis is to use the yielded data to detect potential issues early and prevent costly equipment malfunction and failure.

Key Benefits of Oil Analysis

The viscosity and physical properties of lubricating oil can provide key insight into the health and condition of equipment. Lubricating oils degrade over time due to thermal and mechanical stresses, oxidation, and contamination, and changes in viscosity and composition can impair the lubricant’s ability to protect moving parts by effectively reducing friction.

Regularly scheduled oil analysis can help detect deviations from normal oil properties, allowing corrective actions before damage occurs. Some of the key benefits of lubricating oil analysis include:

- Early Issue Detection

- Contamination Detection

- Minimized Downtime

- Improved Equipment Reliability

- Reduced Maintenance Costs

- Reduced Equipment Replacements

- Compliance with Industry Standards

- Improved Efficiency

The Process of Lubricating Oil Analysis

Our oil analysis experts closely examine lubricants to detect the presence of wear particles and contaminants. Even properly maintained equipment components undergo wear during normal operation that releases metal particles into lubricating oil, and contaminants such as dirt, dust, water, and fuel can enter the oil system as well, leading to accelerated wear and reduced performance.

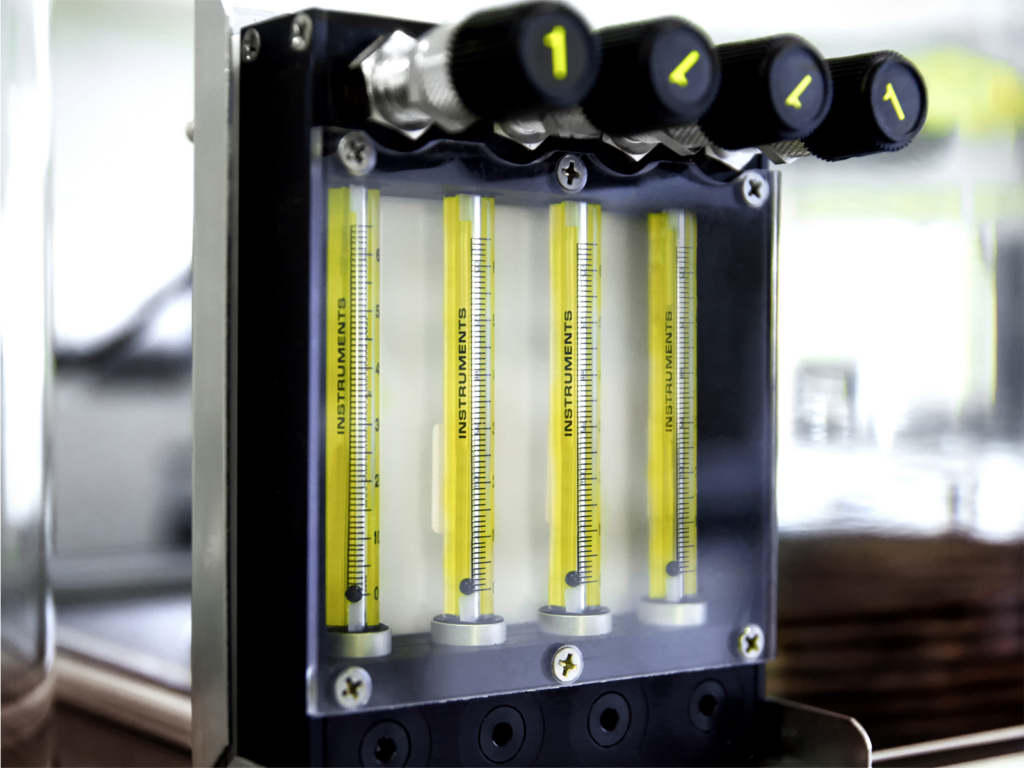

ATS’ highly trained oil analysts conduct techniques such as particle counting and elemental analysis using techniques like inductively coupled plasma to help identify the type and concentration of wear metals and contaminants present in the oil. This information allows our engineers to assess component wear rates, diagnose potential issues with specific parts, and develop maintenance programs to keep your business operations running smoothly.

The Applied Technical Services Family of Companies

With decades of experience, an exceptional reputation for customer satisfaction and service quality, and clients that include some of the most well-established companies in the world, the Applied Technical Services Family of Companies is committed to helping your business thrive.

Submit a request form on this page or give us a call at +1 (888) 287-5227 for additional information or a free quote on lubricating oil analysis services at ATS.