Applied Technical Services, LLC specializes in weld inspections and testing. We test to many different industry standards, including ASME, AWS, API, NAVSEA, MIL-STD, AMS, and PED/EN. In order to meet our clients’ specific welding needs, we offer nondestructive testing for quality control and failure prevention, mechanical testing to measure weld performance, and chemical analysis for alloy identification. In addition, ATS qualifies and certifies welding plate and/or pipe testing coupons.

With decades of experience, ATS has earned an excellent reputation in the manufacturing, power generation, petrochemical, nuclear, automotive, aerospace, steel, and commercial infrastructure industries. Our valued team of experts includes Professional Engineers, Certified Welders, Certified Weld Inspectors, API Inspectors, Scientists, Chemists, Metallurgists, and Certified Technicians.

Nondestructive Testing of Weldments

ATS offers comprehensive NDT inspections that will allow you to properly identify both surface and subsurface flaws and discontinuities. Our NDT division offers the following inspection methods:

- Visual Testing (VT)

- Ultrasonic Testing (UT)

- Traditional Radiography Testing (RT)

- Liquid Penetrant Testing (PT)

- Magnetic Particle Testing (MT)

- Computed Digital Radiography (CDR)

Mechanical Testing of Weldments

ATS’ mechanical testing services help you identify and determine the strength of a weld. Such services are especially valuable during research, development, performance, and procedure qualifications. Our mechanical tests include such highly rated techniques as:

- Tensile Testing

- Lap Shear Testing

- Micro Hardness Testing

- Toughness Testing (Charpy and Drop Weight)

- Hardness Testing

- Load Testing

- Bend Testing

Welder Certifications

Applied Technical Services qualifies and certifies welding test coupons. We test both pipe and plate coupons in a comprehensive way. Coupon testing is one of the single best ways to pre-screen new hires and to make sure employees can meet the requirements of specific codes/standards as they apply to your unique industry. It is an ideal way to provide proof and documentation regarding a welder’s core competency level.

Additional Capabilities

ATS offers many more weld inspection and testing capabilities, including:

- Chemical Analysis — Composition and alloy ID

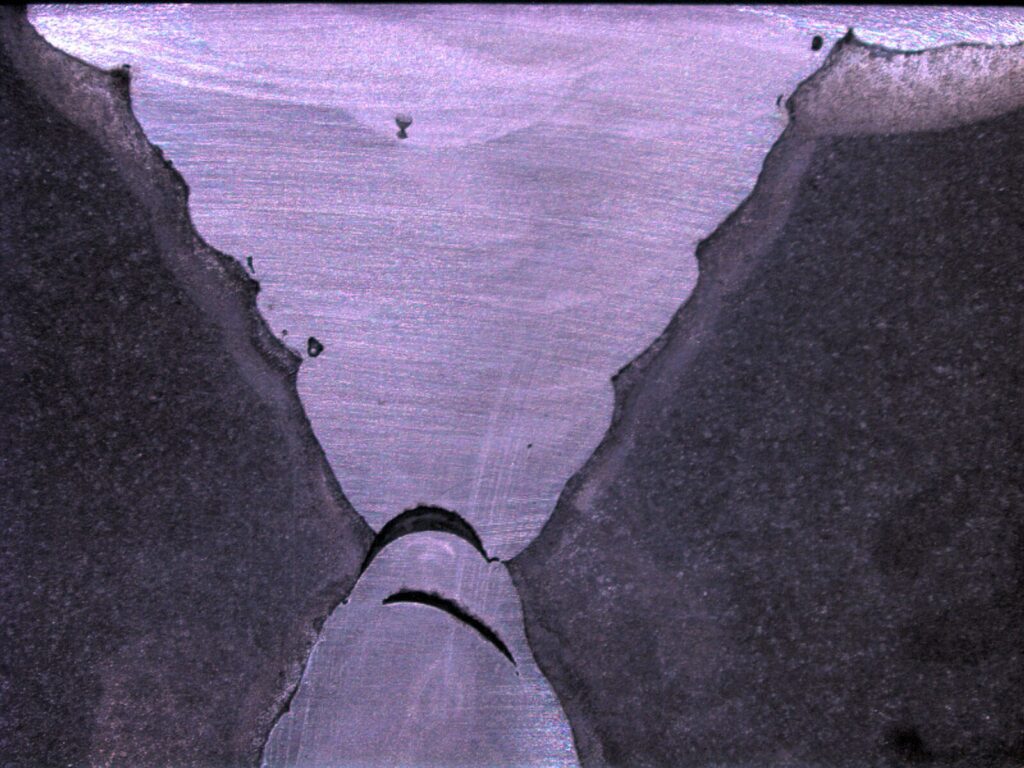

- Macro Etching — Cross-section of a weld used to evaluate the grain structure of a parent metal and welding material

- Ferrite Testing — Assists in measuring the proper balance between ductility, toughness, corrosion resistance, and crack prevention

- Environmental Testing — Accelerated Weathering and Corrosion

- Weld Failure Analysis — Identifies Root Cause of Weld Failures

Contact ATS Today

If your business is searching for a weld inspection provider that can both meet your needs and exceed your expectations, please call us today for more information. Call +1 (888) 287-5227 or click here to request services today.