Identifying A Product’s Lifespan Is Critical In Ensuring Quality Control

Our materials testing department offers accelerated aging testing which is not one specific method but a variety of methods that can determine the life span of your products. The testing methods that we implement are conducted either to internationally-recognized standards or to client specific performance requirements.

Thermal Aging and Weathering Simulation

Altitude Testing

- Temperature range from -65°C to 150°C

- Altitude range from -200 ft to 100,000 ft

- Mil-Std 202G (conditions 105C, A/B/C/F)

- Mil-Std 810G (conditions 500.5)

- RTCA/DO-160G

Life Cycle Testing

- Lifespan Expectations

- Environmental Implications On Certain Products

- Meet Industry Standards and Regulations

- Develop and Fabricate Product Specific Test Set-ups

Salt Spray

- Capture Progression of Corrosion at Intervals

- Corrosion Creepage in Scratched Coatings

- Determine Coating Adhesion

- Evaluate Degree of Rusting

- Measure Degree of Coating Blistering

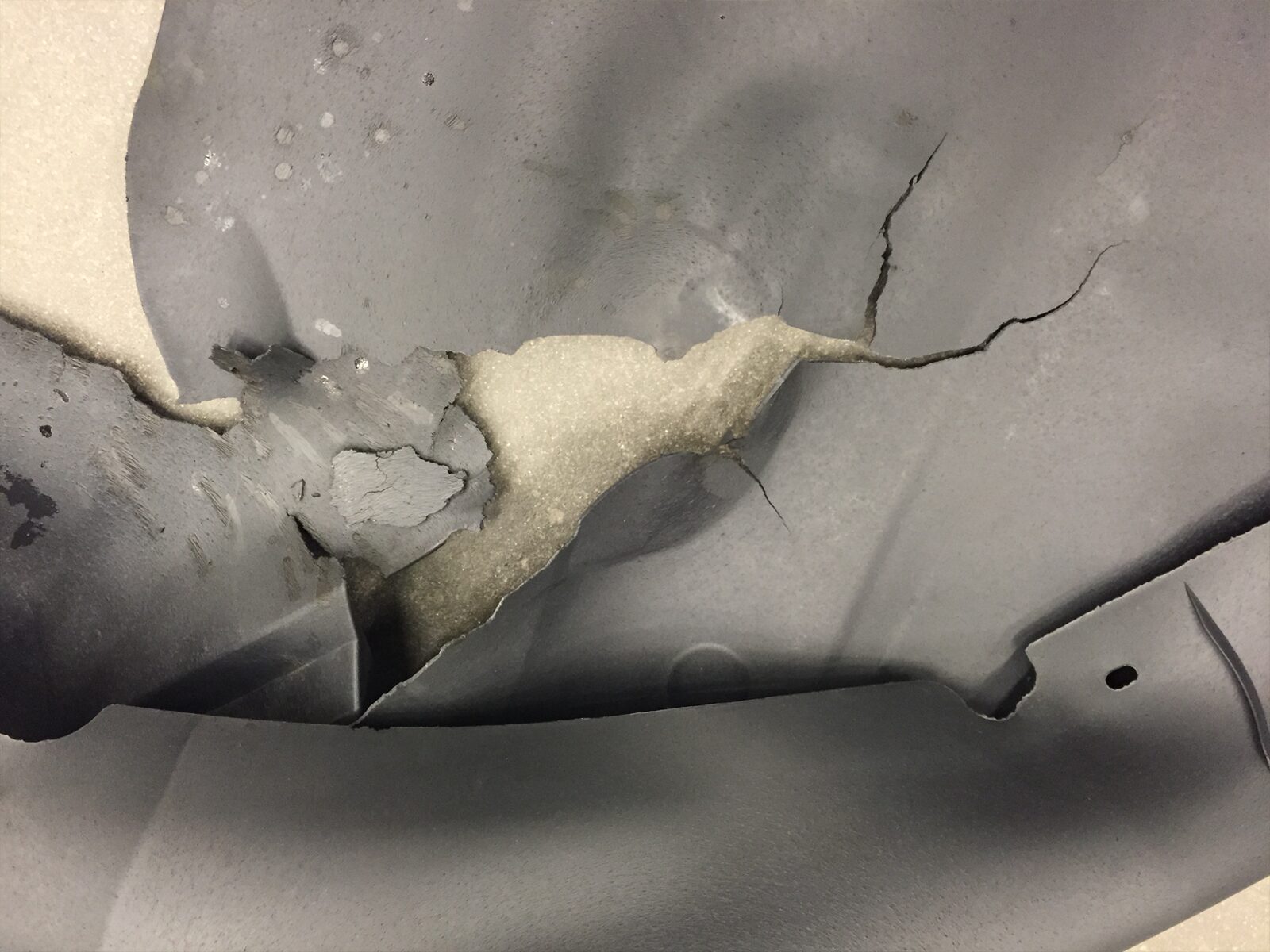

Temperature/Humidity Cycling

- Characterize Thermal Expansion Rates

- Determine Thermal Coefficient Mismatch

- Determine Thermal Shock Resistance

- Heat Aging

- Observe Reaction to Varying Temperature and Humidity Conditions

UV Weathering

- Accelerated UV

- Ultraviolet Exposure

- Xenon Exposure

Xenon Testing

- Evaluate Visual Properties Post Exposure – Color Change, Gloss, Haze, Optical Transmission

- Evaluate Structural Properties of Plastic Parts – Impact Resistance, Tensile Strength, and Abrasion