- Home

- Services/IndustriesServicesindustries

- About Us

- LocationsStatesAccordion ContentAccordion ContentAccordion ContentAccordion Content

- Job Openings

- Quick Links

- ATS Family

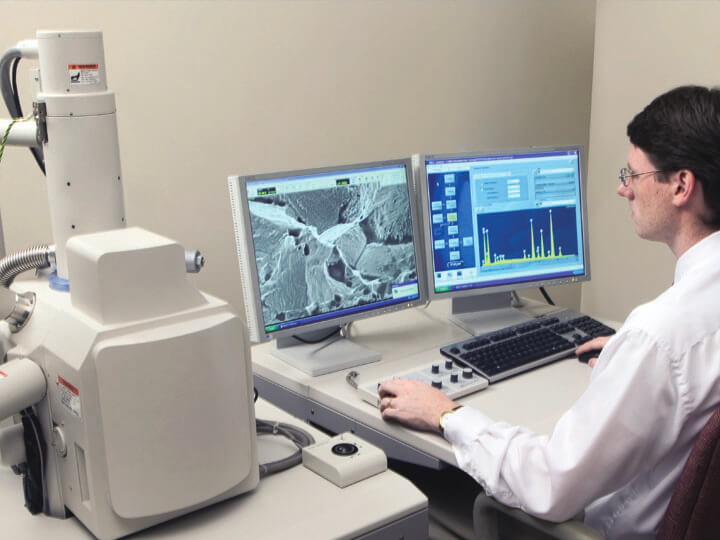

Failure Analysis Services

We Analyze Steels, Stainless Steels, Titanium Alloys, Super-alloys, Copper and Aluminum Alloys, Plastics, Ceramics And Glass

Whether you are investigating a single component or dealing with a complete system failure, you can rely on the ATS Failure Analysis group’s expertise and in-depth knowledge of testing techniques to meet your full failure analysis needs. From fractures to formability problems, corrosion to wear, our analysts will perform a root cause failure analysis and then assist in plans for prevention. Applied Technical Services’ Metallurgists and Professional Engineers routinely conduct these services on a wide variety of materials, including steels, stainless steels, titanium, superalloys, copper and aluminum alloys, plastics, ceramics, and glass.

Request Form

Quote Request Form

Service Details:

- Chemical Analysis Lab

- Consumer Product Testing Labs

- Dimensional Inspection Lab

- Environmental Testing Lab

- Forensic Analysis Lab

- Materials Testing Lab

- Mechanical Testing Lab

- Metallurgical Analysis Lab

- NDT Lab

- Polymer Analysis Lab

- Embrittlement

- Ductility Issues

- Fatigue

- Manufacturing Defects

- Overload

- Wear

- Chemists

- Civil Engineers

- Fire Investigators

- Forensic Investigators

- Industrial Engineers

- Mechanical Engineers

- Metallurgists

- Polymer Specialists

- Scientists

- Structural Engineers

- Trained and Certified Analysts

- Trained and Certified Technicians

- Corrosion

- Formability Problems

- Fractures

- Wear

- Aircraft Parts

- Automotive Parts

- Boiler Components

- Consumer Products

- Fasteners

- Material ID and Contamination

- Piping and Tubing

- Structures

- Blades

- Boiler Tubes

- Bolts

- Bearings

- Fasteners

- Hoses

- Pipes

- Pumps

- Screws

- Shafts

- Springs

- Wire Ropes