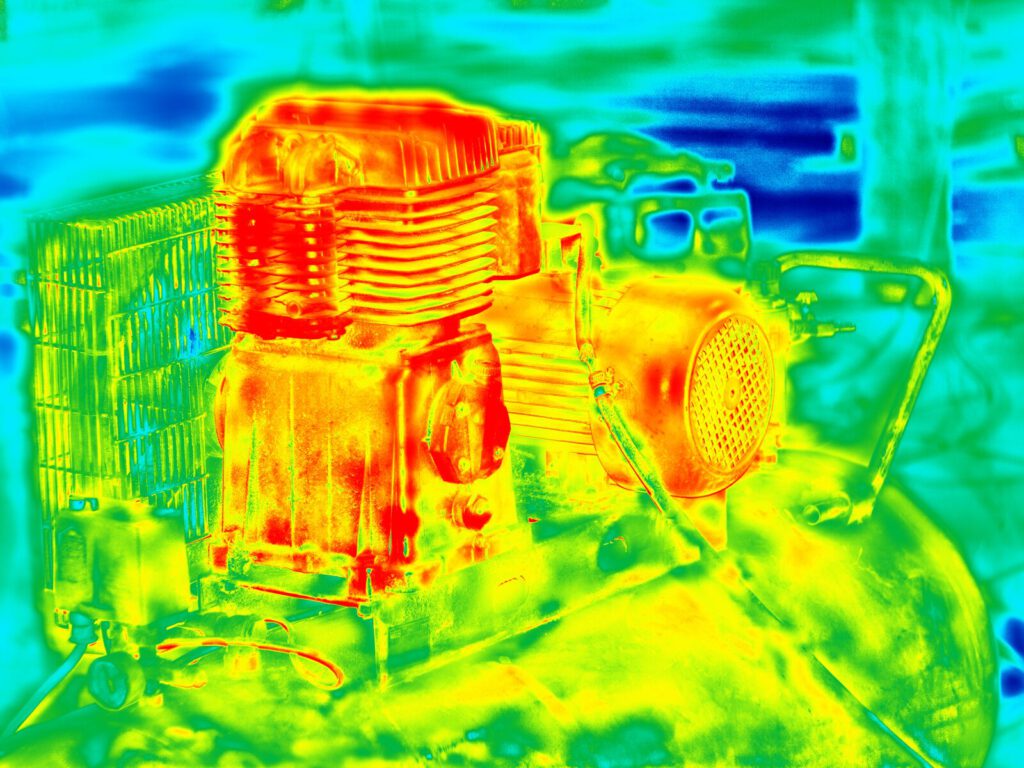

Thermography testing, or thermal imaging, is a method for quickly and accurately measuring temperature in a given area. Thermography works by detecting infrared radiation, a form of invisible energy we feel as heat, and converts the data into an image called a thermogram. This allows technicians to evaluate industrial equipment for temperature differences as little as hundredths of a degree Celsius.

The Reliability Testing Service (RTS) technicians from the ATS Family of Companies (FoC) provide clients with thermographic testing services for a wide variety of applications, discovering impending failures that could interrupt their processes.

Applications for Thermography

Thermographic testing benefits both industrial and commercial clients. Our thermography experts apply this technology to numerous circumstances, from measuring water levels in tanks to identifying thermal defects in building structures.

Other applications for thermography include:

- Electrical surveys: checking for misbalancing, overloading, and connection issues in low- and high-voltage equipment

- Identifying water penetration, humidity, or moisture in aircraft structures, paper, and soil

- Skin surveys: locating areas where insulation and refractory are missing or damaged

- Finding defects in pipes, metal parts, shafts, and plastics

- Mechanical surveys: finding overheating equipment, bearing faults, and lubrication deficiencies

- Detecting materials and structures hidden underground: hidden tunnels, pipes, underground storage tanks, and pipeline leaks

- Identifying construction defects in building envelopes, roofing systems, and insulation

- Finding potential or existing deterioration/failure in electrical and heating systems

Infrared thermography is a safe, efficient nondestructive testing (NDT) method. Our experienced technicians and state-of-the-art equipment make our thermography services a valuable predictive technology to utilize and has several benefits, such as

- Noninvasive and nondestructive testing method

- Non-contact method allows technicians to keep a safe distance

- Suitable for inaccessible and hazardous areas

- No harmful radiation, allowing for repetitive, prolonged use

- Real-time imaging can assess rapidly changing thermal patterns

RTS: Dependable Services

At Reliability Testing Services, our certified experts provide quality services with honesty and integrity, striving to provide clients with the best predictive maintenance services possible. Our technicians are proficient in several technologies, such as passive ultrasonic listening, vibration analysis, and motor circuit evaluation.

We support proactive maintenance practices for a wide array of industries, including:

- Manufacturing

- Oil and Gas

- Pulp and paper products

- Wood products

- Medical facilities

- Office buildings

- Power generation

- Petrochemical

- Consumer/food products

- Power transmission

Our services help clients increase production opportunities, prolong equipment service life, and maintain safe practices. RTS prioritizes our customers’ needs; we deliver clear, detailed reporting as quickly as possible. Clients may contact our experts directly with any questions they have regarding testing or results.

If you need thermography testing, contact RTS today.