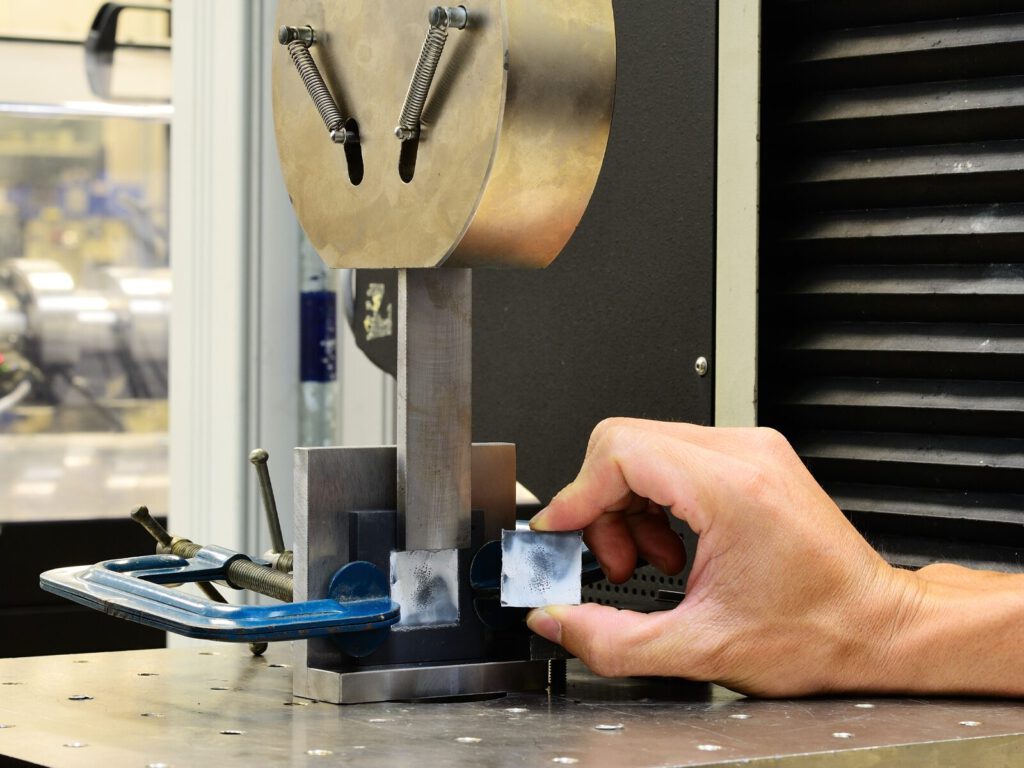

Applied Technical Services provides shear strength testing services to determine the strength of products exposed to shear loads.

The shearing of a material refers to a sliding failure caused by forces that are applied in a parallel but opposing direction, permanently deforming the material as it slides against itself. Because a variety of products may be subject to “shear loads” that can result in failure, it is important to determine the ability of materials to resist these forces.

Shear strength is found by measuring the maximum level of stress that a test material can sustain before it ruptures. Materials that are often tested for shear strength include:

- Adhesives

- Composites

- Fasteners

- Films

- Plastics

Testing Capabilities

ATS employs its skilled mechanical testing lab personnel to provide a variety of shear strength tests. Our technical experts work in accordance with the relevant industry standards for each test method, operating specialized equipment to accurately determine if a given test product is fit for service.

Shear Testing Standards

The most commonly performed shear testing procedures include the following:

- ASTM D732 – Shear Strength Test for Plastics

- ASTM D1002 – Lap Shear Strength of Adhesively Bonded Material Specimens

- ASTM D2344 – Short Beam Shear Testing

- ASTM D3163 – Lap Shear Strength Test of Adhesively Bonded Plastics

- ASTM D3164 – Shear by Testing Loading

- ASTM D3846 – Shear Strength of Reinforced Plastics

- ASTM D5868 – Lap Shear Adhesion Test for Fiber Reinforced Plastic (FRP)

- ASTM F606 – Single Shear Test of Treaded Fasteners (ISO/IEC 17025 (A2LA) Accredited for This Method)

- NASM 1312-13 – Fastener Test Methods for Double Shear Tests

- NASM 1312-20 – Fastener Test Methods for Single Shear Tests

Applied Technical Services – A Reliable Testing Provider

Since our founding in 1967, ATS has expanded the scope of its reliable testing and inspection services to include Metallurgy, Materials Testing, Chemical Analysis, Nondestructive Testing, and Forensic Investigations. We work with clients from a wide range of industries, including those in the fields of aerospace, automotive, construction, consumer products, defense, manufacturing, and power generation.

ATS Labs and Lab Experts Deliver Quality Assurance

At ATS, we are committed to the process of continuously improving the excellence of our services by following the relevant quality standards of each industry we serve.

We have an ISO 9001:2015 registered quality management system and employ a variety of skilled experts — including metallurgists, investigators, scientists, chemists, well-trained technicians, and Professional Engineers of various disciplines. ATS’ accreditations and certifications include ISO 9001:2015-2015, Nadcap, recognition as an FAA Repair Station, and many more.

ATS is committed to the following policies:

- Employ Qualified and Engaged Employees

- Conduct Testing and Inspections Following Applicable Standards

- Provide Clear and Accurate Data

- Deliver All Professional Services in A Timely Manner