The Applied Technical Services Family of Companies offers vibration analysis of induction motors services to identify potential issues and help clients maintain optimal efficiency.

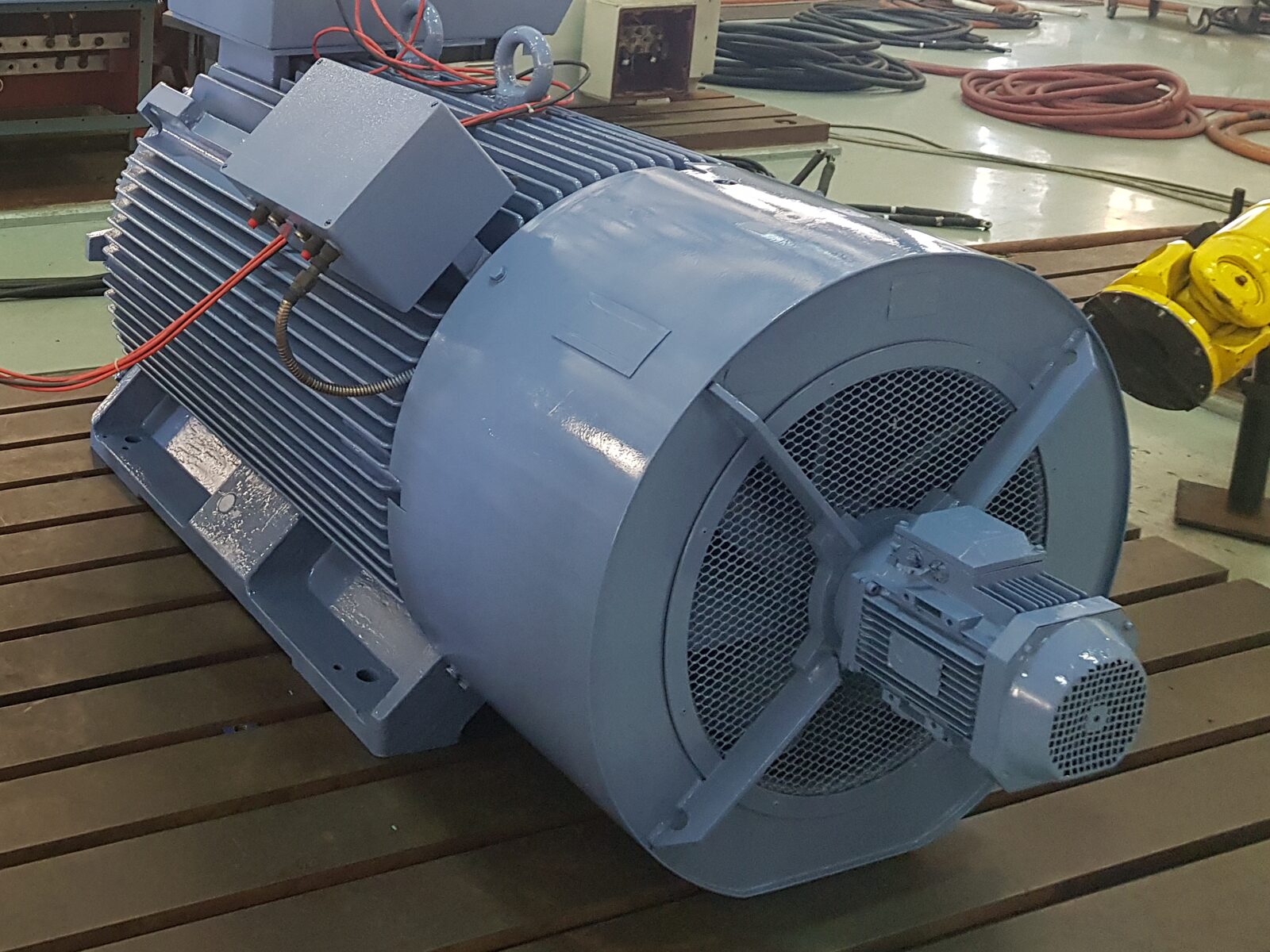

Motor Vibration Analysis

Performing vibration analysis for induction motors can help predict maintenance needs by assessing the condition and health of a motor system. Predictive maintenance can help prevent unexpected downtime, costly repairs, safety hazards, diminished efficiency, and even the need to replace equipment prematurely by increasing the motor’s life expectancy.

ATS’ vibration testing experts conduct vibration analysis of induction motors as follows:

- Vibration Analysis Equipment and Test Subject Preparation

- Vibration Sensor / Accelerometer Placement

- Observation and Data Collection

- Data Analysis

- Frequency Analysis

- Standard / Baseline Comparison

- Fault Identification and Diagnosis

- Condition Assessment

- Reporting

Vibration Analysis of Induction Motors Benefits

Preventative maintenance through vibration monitoring allows the identification of problems before they become significant. As is the case with all preventative maintenance, performing induction motor vibration analysis offers several benefits, including but not limited to:

- Early Detection: identify potential faults and flaws before they cause significant issues or require repairs.

- Increased Reliability: staying ahead of necessary maintenance helps reduce and potentially eliminate downtime and service interruptions.

- Performance Optimization: addressing problems before they reduce functionality helps keep your equipment and business running efficiently.

- Reduced Costs: taking preemptive measures to address minor issues is significantly more cost-effective than costly repairs and replacements.

- Improved Safety: prioritize the safety of your personnel and equipment by addressing minor problems before they cause malfunction or catastrophic failure.

- Informed Decisions: the valuable insights provided by preventative vibration analysis allows clients to make informed decisions about repair actions, maintenance priorities, and replacement plans.

- Regulatory Compliance: preemptive maintenance helps your business stay ahead of industry standards and regulations by taking a calculated approach to quality and safety standards.

- Long-term Asset Management: applying vibration analysis preventative maintenance to your asset management program assists in long-term planning, helping to allocate resources for scheduled repairs.

Applied Technical Services: The Vibration Analysis Experts

With nearly six decades of business experience, the Applied Technical Services Family of Companies has the industry-leading staff, state-of-the-art testing facilities and laboratories, and steadfast dedication to clients that will help your business succeed.

Get more information or a free quote by submitting the request form on this page, or give us a call at 1 (888) 287-5227 to speak with one of our customer service team members.