- Home

- Services/IndustriesServicesindustries

- About Us

- LocationsStatesAccordion ContentAccordion ContentAccordion ContentAccordion Content

- Job Openings

- Quick Links

- ATS Family

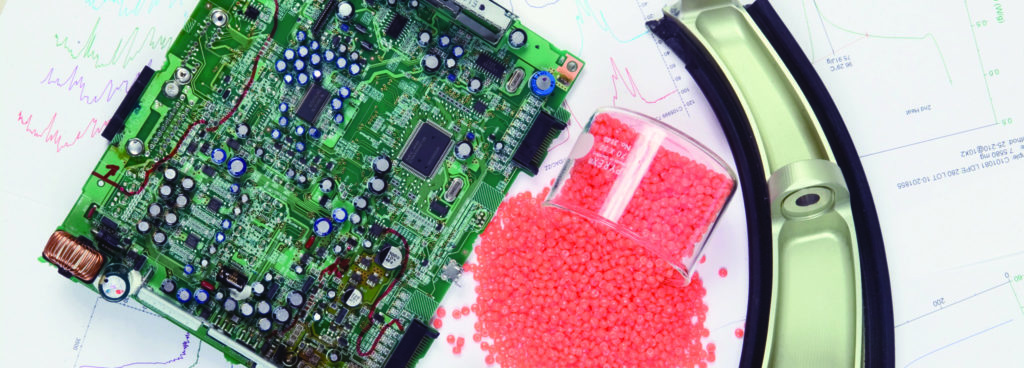

Polymer Testing and Analysis

Polymer analysis and testing employs both physical and analytical methods to verify the chemical, mechanical, and thermal properties of a polymeric material. These properties are instrumental in making sure that the polymer part will perform as required by the end user.

For example, we can verify if the parts are the proper material using FT-IR, check for contamination using DSC, and then determine if the parts are degraded using the melt flow indexer. Additionally, mechanical tests such as durometer hardness, izod impact, tensile, and flexural strength are useful in determining the mechanical integrity of a part.

We perform polymer testing and analysis by using our FT-IR to determine the composition of organic thin films, surface contamination, fibers or composites. Additionally, thermal characterization can assist in determining performance, process capabilities, quality, and aid in product development.

Polymer Testing and Analysis Capabilities

- Failure Analysis of Plastics and Polymers

- Tensile Strength of Films, Fibers, and Coatings

- Flexural Strength

- Modulus by Dynamic Mechanical Analysis (DMA) or Thermomechanical Analysis (TMA)

- Durometer Hardness

- Flammability

- Compression Set for Durability and Elasticity

- Izod, Charpy, Impact Testing

- Heat Deflection Temperature Under Load (DTUL)

- Coefficient of Thermal Expansion (CTE) by TMA

- Heat Aging and Thermal Stability

- Accelerated Weathering (UV degradation)

- Dielectric Strength/Breakdown

- Glass Transition (Tg), Melting point, Crystallinity, and Heat Capacity (DSC)

- Gloss and Color

- Filler Content, Dehydration/Desolvation, and Decomposition Analysis (TGA)

- Polymer Identification (FT-IR)

- Inherent/Intrinsic Viscosity

- Melt Flow Rate

Request Form

"*" indicates required fields

Chemical Analysis

- Ash Testing

- Azo Dyes

- Azo Dye Testing

- Benzene Analysis

- Biocompatibility Testing for Medical Devices ISO 10993

- Chemical Composition Testing Lab

- Cleanliness Testing Lab

- Contamination Test

- Combustion Analysis

- CPSIA Testing Lab

- DSC Analysis

- DSC Analysis of Polymers

- DSC Polymer Characterization Analysis

- DSC Testing

- Ethylene Oxide GC MS Analysis

- EPA Method 24 Testing

- Extractables Leachables Testing

- Extractables Testing

- Flame Retardant Chemicals

- Formaldehyde Testing

- FTIR Analysis

- FTIR Chemical Analysis

- FT-IR Material Analysis

- FTIR Surface Analysis

- FTIR Testing

- Gas Chromatography Mass Spectrometer Analysis

- GCMS Analysis and Testing

- GCMS Oil Analysis

- Halide Anion Testing

- HPLC Analysis Services

- ICP-AES Analysis

- ICP-OES Testing

- ION Chromatography Testing

- ISO 10993 Testing

- ISO 10993 Testing Lab

- Karl Fischer Testing

- Leachable Testing

- LECO Testing

- Melting Point Analysis

- Methane Analysis Gas Chromatography

- Methanol Contamination Testing

- OES Materials Testing

- Optical Emission Spectroscopy

- PAH Testing

- Particle Size Distribution Analysis

- Particle Size Distribution Analysis Laboratory

- Particle Size Distribution Testing

- PFOA Testing

- PFOS/PFOA Testing

- Plastic Impact Testing

- Plastic Pipe Testing

- Polymer Characterization Lab

- Polymer Material Testing

- Polymer Testing and Analysis

- Powder Characterization

- Product Formulation

- Solvent Testing Lab

- TGA Analysis

- TGA DSC Analysis Lab

- TGA Moisture Analysis

- TGA Polymer Testing

- Thermal Analysis Services

- UV VIS Testing

- VDA 19.1 Cleanliness Testing Lab

- Ventilator Component Cleanliness Testing