The Applied Technical Services Family of Companies offers failure mode and effects analysis services to identify potential failure causes and effects and create preventative solutions.

Root Cause Analysis vs. Failure Mode and Effects Analysis

As one of the leading failure analysis service providers in the country, Applied Technical Services features cutting-edge laboratories, highly advanced failure analysis technologies and equipment, and a staff consisting of some of the leading failure analysis experts in the industry. Our services range from root cause analysis and failure mode and effects analysis to failure analysis consulting. While these services sound similar, they are different steps and approaches to the failure analysis process.

Root Cause Analysis

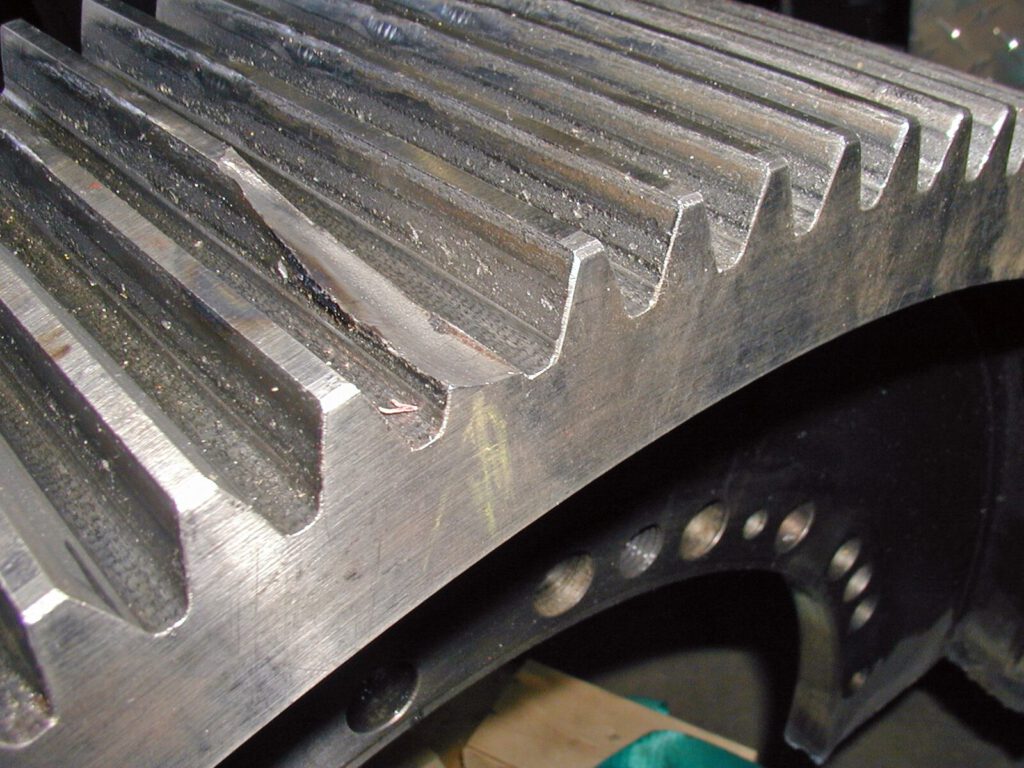

Root cause analysis, or RCA, consists of an investigation into a past incident that ended in material, component, device, or system failure. This is a reactive process intended to identify the exact cause of an accident for purposes ranging from maintenance and repair to litigation.

Failure Mode and Effects Analysis

FMEA is a systematic approach to identifying potential failure modes or causes that could lead up to a failure incident that has not yet happened. FMEA is preventative and is often used during the design phase of processes like manufacturing, building, and construction. FMEA can expose potential vulnerabilities, bottlenecks, or other inefficiencies that could lead to failure as minor as a short service interruption or as severe as a catastrophic failure. This type of failure analysis is intended to construct and implement preventative measures to mitigate risks and ultimately improve overall reliability.

Failure Analysis Consulting

Failure analysis consulting typically relies on multidisciplinary failure analysis methods. Failure analysis consulting teams incorporate chemical analysis, metallography, corrosion testing and analysis, and mechanical testing.

Applied Technical Services offers root cause analysis, failure mode and effects analysis, failure analysis consulting services, and several other types of failure analysis to meet the needs of our clients operating across industries including:

- Aerospace

- Building & Construction

- Aviation

- Consumer Products

- Automotive

- Manufacturing

- Power Generation

- Oil & Gas

- Pulp & Paper

- Nuclear

- Renewable Energy

- Life Science

The Applied Technical Services Family of Companies

Between our decades of business experience, nationwide service network of state-of-the-art testing facilities and laboratories, industry-leading testing experts, exceptional customer service team, and unwavering dedication to service quality, Applied Technical Services is the premier choice for failure mode and effects analysis services.

Submit a request form on this page or call us at 1 (888) 287-5227 for a free quote or additional information on FMEA services.