Condition Monitoring Advantages

Condition monitoring is a non-destructive method for analyzing machine characteristics and searching for changes that may indicate deterioration or damage. Locating and Identifying problems early helps to avoid failures, breakdowns, and collateral damage. Condition monitoring helps maintain proactive control over maintenance programs, reducing unexpected downtime and repair costs. Vibration-based condition monitoring is a form of observation that interprets machine vibration characteristics to diagnose issues with equipment health. Vibration monitoring findings can also help optimize machines to run faster or with increased loads, reducing the overall operating costs. Machinery operating at peak efficiency lasts longer with condition monitoring than with run-to-failure tactics.

Using Vibration Analysis

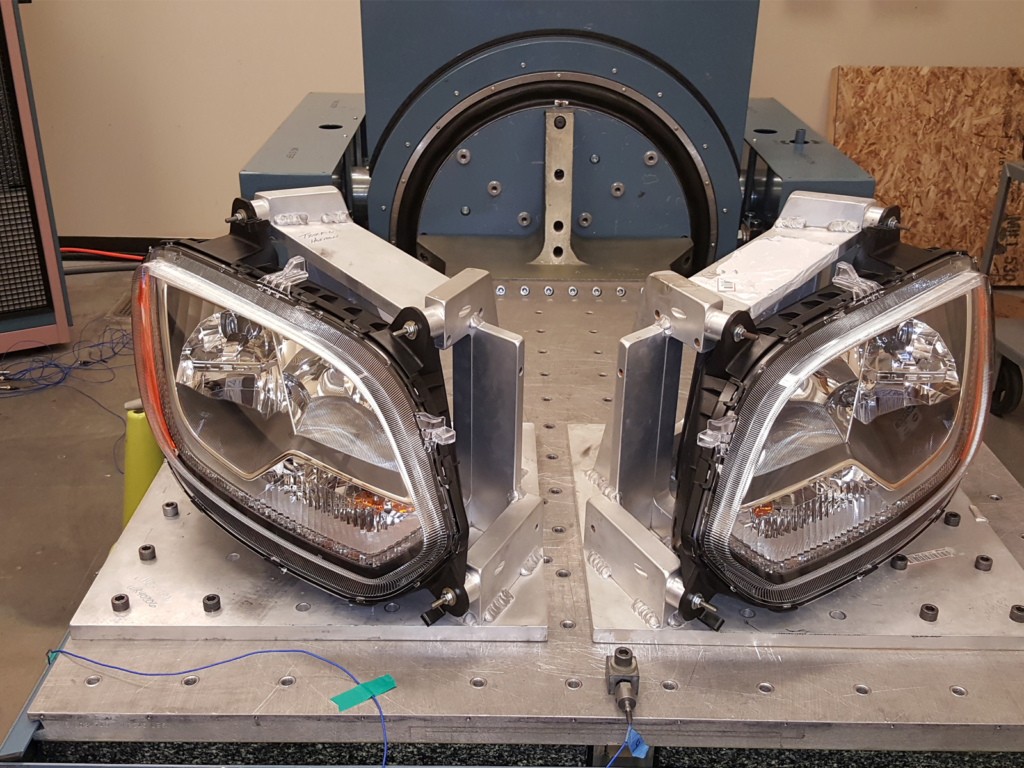

Vibration analysis is a versatile predictive testing science with a wide range of applications. Vibration monitoring uses testing, surveillance, and analysis to find potential issues with misalignment, bearings, drive belts, imbalance, pulleys, gearboxes, resonance, electrical supply, motors, and other components. Reliability Testing Services provides vibration-based condition monitoring as a program that we can set up from scratch, establishing routes, alarm limits, and monitoring frequencies, or supplement existing condition monitoring programs. Vibration monitoring programs indicate early signs of malfunction or deterioration, allowing proprietors to plan repairs or replacements before failure occurs.

Vibration can have a direct impact on product quality; excessive vibrations in paper machines and aerospace machine spindles can damage the product. Routine condition monitoring programs collect and trend data that can help prevent equipment performance issues. At RTS, our certified, experienced vibration analysts deliver clear, accurate data that allows clients to take prompt, informed actions regarding their equipment, scheduling maintenance only when necessary. Our experts also offer balancing and alignment services to help optimize equipment performance.

Vibration Monitoring with RTS

Reliability Testing Services works to minimize client costs, downtime, and safety risks while maximizing the value of our vibration analysis services. We help clients increase their production opportunities using advanced predictive maintenance technologies, such as passive ultrasonic listening and infrared thermography. Our qualified experts can establish a program that best suits your needs. As leaders in reliability testing, we serve both industrial and commercial clients from various industries, such as manufacturing, petrochemical, and medical facilities. We aim to offer exemplary customer service; our customer service team connects clients with the most relevant available expert who can help answer any of their questions. We present detailed findings that give clients a comprehensive understanding of their equipment’s health, so they can decide what actions they need to take.

If you could benefit from vibration-based condition monitoring, contact RTS today.