- Home

- Services/IndustriesServicesindustries

- About Us

- LocationsStatesAccordion ContentAccordion ContentAccordion ContentAccordion Content

- Job Openings

- Quick Links

- ATS Family

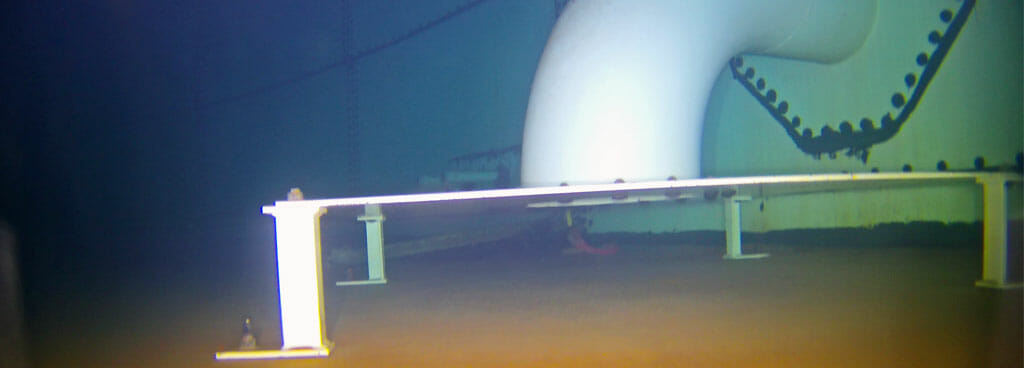

ROV for Underwater Inspection

Applied Technical Services utilizes submersible remote operated vehicles (ROV’s) for underwater inspections of water tanks. Our ROV’s allow ATS to conduct thorough condition assessments on client equipment in accordance with the following standards:

Submersible ROVs allow inspectors to evaluate fixed equipment below the waterline without necessitating confined space entry or major diving operations. We can conduct comprehensive examinations of all your equipment’s surfaces without risking personnel safety.

Underwater ROV Experts

ATS’ licensed, certified, and highly trained ROV experts provide true condition assessments for fixed equipment. We can assess every part and component related to equipment health, including sidewalls, floor plates, pipes, ladders, hatches, and roof plates with our remotely controlled camera equipment. ROV technology also allows us to perform in-service inspections. ATS’ certified API inspectors and licensed Professional Engineers collect accurate data that helps fixed equipment owners plan future shutdowns, schedule additional inspections, and budget for repairs. As a third-party tank consulting company, ATS has the necessary equipment and expertise to handle any client’s fixed asset needs.

Systematic Inspection Programs

Maintaining a systematic inspection program can lower the risk of containment loss in fixed equipment, promoting safety for personnel and the surrounding environment. Extending the time between inspections beyond the recommended length can result in problems with coating failure, corrosion, excessive debris, sediments, and contamination. Corrosion is a leading cause of fixed asset failure and poses an increasing risk the longer it’s left unchecked.

Applied Technical Services offers routine inspection programs to keep fixed equipment in proper shape. We can identify damaged parts and potential issues early, assessing every aspect of equipment health from standard compliance to weld quality. Our engineers can calculate repair plans and give your repair contractor a detailed scope of needed repair work before repair operations begin. ATS maximizes our inspection value by using practical condition assessments to help clients minimize their downtime. Our condition assessments allow clients to prioritize their equipment’s needs with a detailed understanding of their assets’ condition.

Mechanical Integrity Services

ATS monitors fixed equipment conditions and offers process safety management (PSM) through our mechanical integrity programs. Whether you need fitness for service assessments for piping or underwater ROV inspections, we can develop or assess your program to ensure that it meets your specific needs. Our mechanical integrity programs generally address the following:

- Applicable standards

- Frequency and methods of inspection

- Program ownership and management

- Jurisdictional regulations

Applied Technical Services offers mechanical integrity services for pipes, tanks, pressure vessels, and other related equipment. We can identify numerous issues, such as external and internal corrosion, corrosion under insulation, flow-accelerated corrosion, cracking, fatigue, erosion, and manufacturing flaws.

Underwater ROV technology enables us to offer more cost-effective inspections and detailed documentation. We can examine essential equipment, including fire protection water tanks, without water loss, enabling the equipment to continue essential functions without disruption. ATS can also provide several other inspection methods for evaluating system health without impacting equipment integrity, including magnetic particle testing, bubble leak testing, penetrant testing, ultrasonic thickness testing, and radiographic testing. Our certified experts can assist clients in determining which of our services best suits their needs.

Excellent ROV Services

Applied Technical Services is dedicated to providing the best possible underwater ROV inspection services. For over fifty years, we have continuously expanded our range of testing, inspection, and consulting services while prioritizing customer satisfaction. Our comprehensive mechanical integrity capabilities benefit several industries, such as:

- Manufacturing

- Nuclear

- Industrial

- Construction

- Energy

- Chemical

- Pharmaceuticals

- Government

- Pulp and paper

- Commercial Properties

- Oil and gas

- Military

ATS experts prioritize safety, accuracy, detailed reporting, and quick turnaround times. Our ISO 9001 certified quality regulation system keeps us accountable to our clients. We maintain contact with clients throughout the inspection process to keep them informed about their equipment’s health. Our customer service team helps clients with questions about test results or data and connects customers to relevant experts to assist with their inquiries.

If you need an ROV for underwater inspection, contact Applied Technical Services today to get a free quote. At ATS, we take a closer look.

Request Form

"*" indicates required fields

Camera Inspections