ATS’ fatigue testing methods produce thorough analyses and innovative solutions to your questions. When a material undergoes fatigue, it loses strength and can eventually fail. If excessive fatigue occurs in critical structures and machinery components, devastating consequences can ensue:

- Loss of life

- Serious injury

- Component failure

- Work stoppage

- Collateral damage

Fatigue tests uncover critical data about a material’s ductility and fatigue life. We provide manufacturers, vendors, and end-users with thorough research and comprehensive reports that enable informed decisions for product design, development, purchase, and replacement.

Our Fatigue Tests

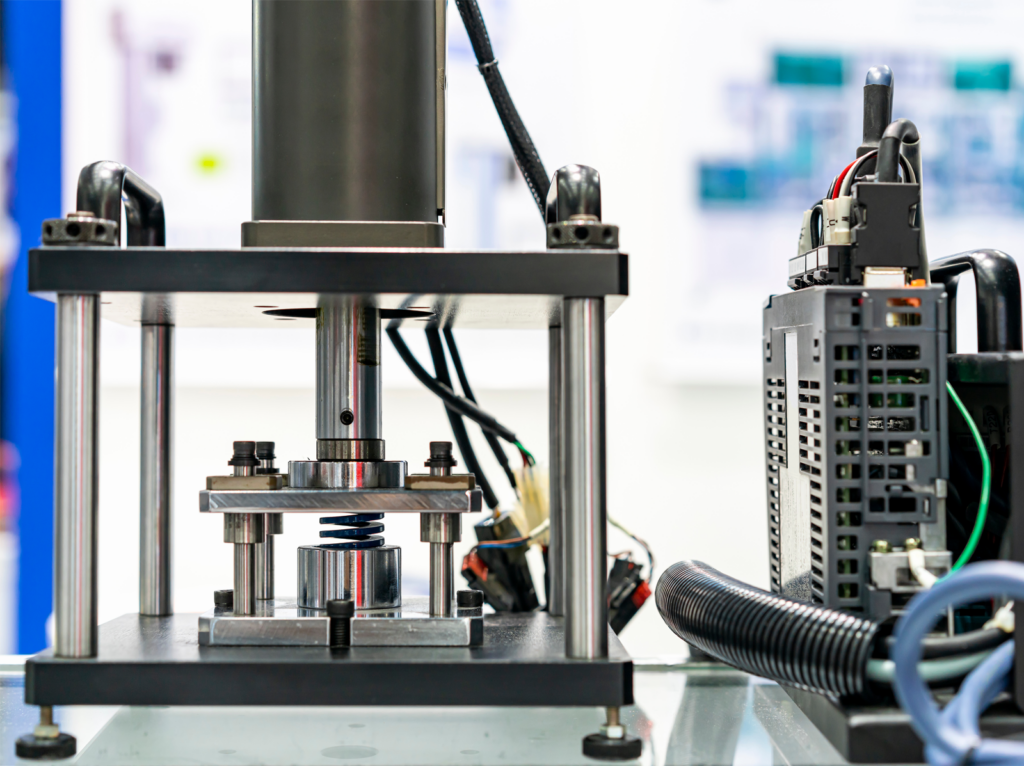

ATS performs multiple fatigue testing methods in our mechanical testing laboratory. We work with a range of materials, such as metals and polymers, using cutting-edge technology.

Our most popular fatigue tests include:

- Cyclic fatigue testing

- Corrosion fatigue testing

- Fatigue crack growth testing

- Spring fatigue testing

- Polymer fatigue testing

- Custom testing

Cyclic fatigue testing uses low and high level cycles of load forces to study the impact of cyclic loads on a material over time. Fatigue crack growth testing measures the growth of a crack under loading and unloading forces.

We also perform fatigue tests based on materials and their intended uses. Spring fatigue testing studies a spring’s endurance under compressive and extensive forces. Polymer fatigue testing determines fatigue-resistance to estimate the life cycle of polymers. Finally, we offer custom testing fabricated from scratch to suit a client’s specific needs regarding any variable contributing to fatigue.

During fatigue testing, technicians can machine an initial point of damage into the sample material. Next, we apply varying loads or environmental factors, such as temperature and corrosive chemicals, to simulate the environment and forces a component or structure is subject to during service.

We often test specimens in conditions harsher than their intended environments to accelerate the testing process and ensure their endurance. Our equipment can reach a temperature of 1000 degrees Celsius and a load capacity from 2 pounds to 55 Kip.

The test ends when failure occurs. Afterwards, our expert engineers and technicians record their assessments and data in comprehensive reports to inform your next steps.

Standards and Accreditations

We are an ITAR and CPSC-approved company for product testing and confidentiality. As an ITAR-secure company, we are also capable of performing our tests and analysis with discretion and confidence. Our experts can fine-tune their testing parameters to follow industry standards:

- ASTM

- MIL-STD

- SAE

- FAA

About ATS

ATS empowers clients to make informed decisions based on our consulting engineering, calibration, testing, and inspection services. Founded in 1967, we now reach clients across the United States and companies worldwide. We promote a work culture of high-quality customer service with a quick turnaround rate that enables clients to make informed decisions at their convenience.

Our state-of-the-art lab provides more than enough room for new ideas and technology to take shape. We are proud to maintain a Quality Management System recognized by ISO. Our labs are also ISO/IEC 17025:2017 accredited in mechanical, electrical, chemistry, calibration, and nondestructive testing. For more information about our accomplishments, click here.

Contact Us

Call +1 (888) 287-5227 to learn more about how our fatigue testing methods can help you. To submit a request for our services, call our number or complete the form on this page.

Whether you need us to test for compliance with an industry standard or build an entire testing procedure from scratch, you can count on ATS to test quickly and thoroughly according to your requirements.