- Home

- Services/IndustriesServicesindustries

- About Us

- LocationsStatesAccordion ContentAccordion ContentAccordion ContentAccordion Content

- Job Openings

- Quick Links

- ATS Family

Contamination Testing Lab

Applied Technical Services’ contamination testing lab serves clients by determining whether the chemical purity of their product’s component materials has been compromised in any way by contaminating agents. Our team of chemists accomplishes this by using a variety of methods, selecting the one most appropriate for each sample material. Whether clients need contamination testing for material qualification or failure analysis purposes, ATS is well-equipped to serve their needs.

Our Methods of Analysis

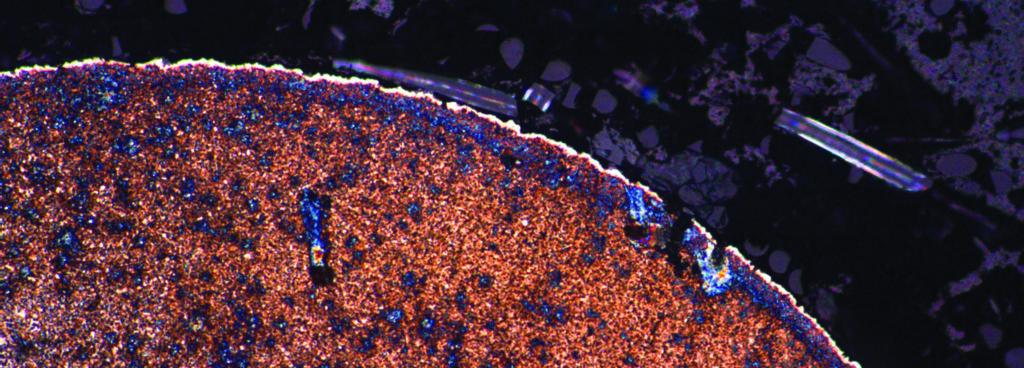

The chemists who staff our contamination testing lab are very experienced in identifying a wide variety of contamination occurring from plant production lines or processes. Our Scanning Electron Microscope (SEM) and Fourier Transform Infrared Spectrometer (FTIR) are key tools in solving contamination issues. Inductively Coupled Plasma (ICP) and Ion Chromatography (IC) are also useful tools in determining the elemental makeup of a sample. Our main focus in contamination testing is to identify the contaminant and to help you determine where it is coming from so that you can eliminate it.

The FTIR is used to identify organic materials such as polymers, adhesives, organic residues and lubricants. We have over 60,000 spectra in our spectral libraries for comparing unknown spectra. We have two FTIR spectrometers in house including a micro-FTIR with a built in microscope useful in analyzing organic thin films, surface contamination, fibers or composites.

Our Hitachi S-3700N scanning electron microscope (SEM) is outfitted with a light element Oxford/Link energy dispersive spectrometer (EDS). The SEM boasts a very generous depth of field with a magnification range of 5 to 200,000X. Through the use of the SEM/EDS techniques, we can determine the elements present in the contaminant.

Contamination Testing Lab Services

- Identification of contaminants in plastic

- Analysis of metal chips, filings, etc.

- Determination of oil contamination

- Automotive component cleanliness testing

- Analysis of hydraulic oils and lubricants

- Particle size determination of fine particles

- Paint bonding failure

- Printed circuit board cleanliness testing

- Ionic contamination using IPC standards

- Medical Device Cleanliness

Request Form

"*" indicates required fields