Applied Technical Services provides salt fog corrosion testing as one of our many environmental testing capabilities. Many industries need their parts, materials, and coatings to withstand corrosive environments since corrosion is a leading cause of equipment failure. Bridges, automotive components, piping systems, and hand tools all need to have corrosion-resistant properties for optimal performance. Salt fog tests, also called salt spray tests, help clients predict how their sample will perform in corrosive conditions before putting a final product into service. Salt fog testing accelerates the weathering process, producing rapid results on an accelerated timeline.

Salt Fog Testing Methods

ATS offers a wide array of salt fog tests according to numerous standards, such as ASTM, ISO, MIL-STD, SAE, DIN, BS, and JIS, alongside various automotive standards for Ford, General Motors, Chrysler, and Nissan.

Standard Tests

Salt fog tests generally use a 5% sodium chloride (NaCl) solution to evaluate how samples resist corrosion. Fundamental salt fog tests can apply to numerous materials, including metals and alloys, conversion coatings, organic coatings on metallic materials, anodic oxide coatings, and anodic and cathodic metallic coatings. ATS also offers corrosion tests using a synthetic seawater solution, more closely mimicking real-world service conditions.

Acetic Acid Salt Spray Testing

The AASS (acetic acid salt spray) test modifies the NaCl solution by adding glacial acetic acid, thus lowering the solution’s pH. The AASS test is more aggressive than basic salt fog tests and is applicable to materials such as anodic coatings on aluminum and decorative chromium, copper, and nickel coatings. We offer acetic acid corrosion testing according to standards such as:

- ASTM G85 A1

- ISO 9227

- BS 7479

- GM 4466P

Copper Acetic Acid Salt Spray Testing

The CASS (copper accelerated acetic acid salt spray) is an accelerated corrosive test that modifies the standard 5% NaCl solution with glacial acetic acid and copper chloride additives. This solution is highly aggressive, so CASS tests generally run for less than forty-eight hours, making this a quick and effective method for evaluating a sample’s durability.

CASS testing allows clients to test materials intended for severe service conditions, including plastics; decorative chromium, copper, and nickel; anodic coatings on aluminum; and zinc and aluminum alloys. Our CASS testing capabilities include the following standards:

- ASTM B368

- ISO 9227

- BS 7479

- JIS H 8502

- JIS H 8681

- Ford BQ5-1

- GM 4476P

- NES M0138

Static and Cyclic Tests

Salt fog tests can be static or cyclic in nature. Static tests hold samples under consistent corrosive conditions, while cyclic tests employ a series of unique environments in a repeating sequence. Cyclic testing procedures usually adhere to a set of phases: salt fog, drying, condensing humidity, and then controlled temperature humidity. ATS tests to several cyclic salt fog standards, such as:

- ASTM G85 A2

- SAE J 2334

- SAE J 1563

- GM 9540P

- GMW 14872

ASTM B117 Corrosion Testing

The ASTM B117 salt fog test standard outlines the proper setup for salt fog chambers in order to keep corrosion testing conditions consistent and repeatable between different labs and chambers. ASTM B117 establishes a standardized corrosive environment on which numerous other standards base their tests. We utilize the following standards based on ASTM B117:

ATS Salt Fog Testing

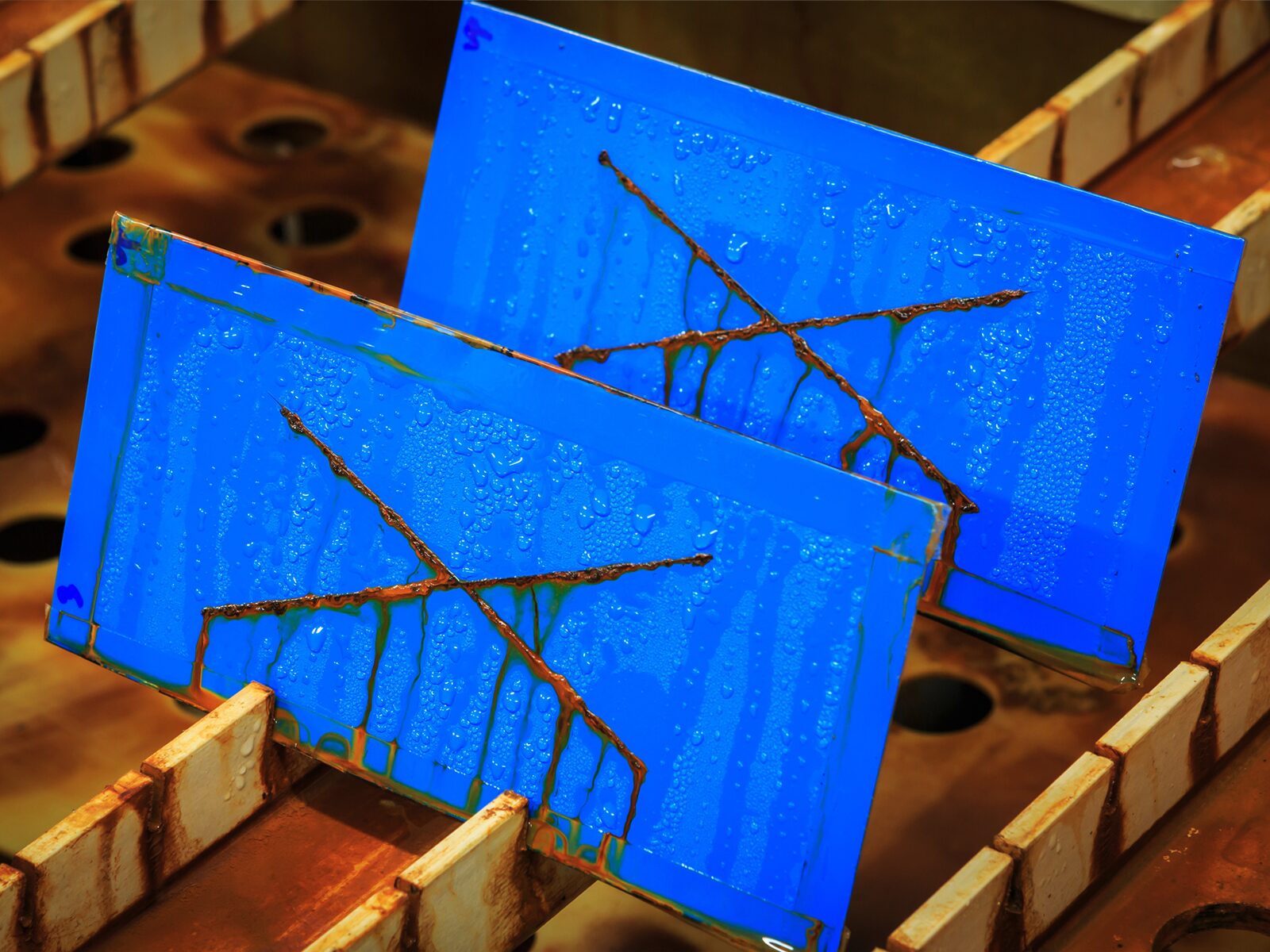

Applied Technical Services’ salt fog services allow clients to accurately predict their products and materials’ service life expectancy. We offer efficient, cost-effective, well-standardized, and repeatable testing using our diverse assemblage of testing equipment. Our experts monitor the samples throughout the testing process, noting milestones such as the appearance of white or red rust.

We can take detailed photos of samples at specified intervals throughout the test. Our report also contains the details of the test chamber conditions, such as temperature, pH, and specific gravity, as well as the chamber’s (and supporting equipment’s) calibration and compliance data. The quantitative data we report includes the percentage of blistering and the degree of creepage from any scratches in the coatings.

Outstanding Service

ATS has provided a wide array of testing and inspection services since our founding in 1967. We have grown our weathering and corrosion capabilities to encompass numerous testing standards at several of our locations. In addition to salt fog testing, we perform:

- Color evaluations

- Fluorescent UV

- Thermal Shock

- Xenon Arc

- Heat aging

- Altitude testing

- Temperature and humidity cycling

Our experts are responsive and willing to answer questions regarding our testing services. We offer detailed, accurate reporting with quick turnaround times.

If you need salt fog corrosion testing, contact ATS for a closer look.