Weathering Exposure

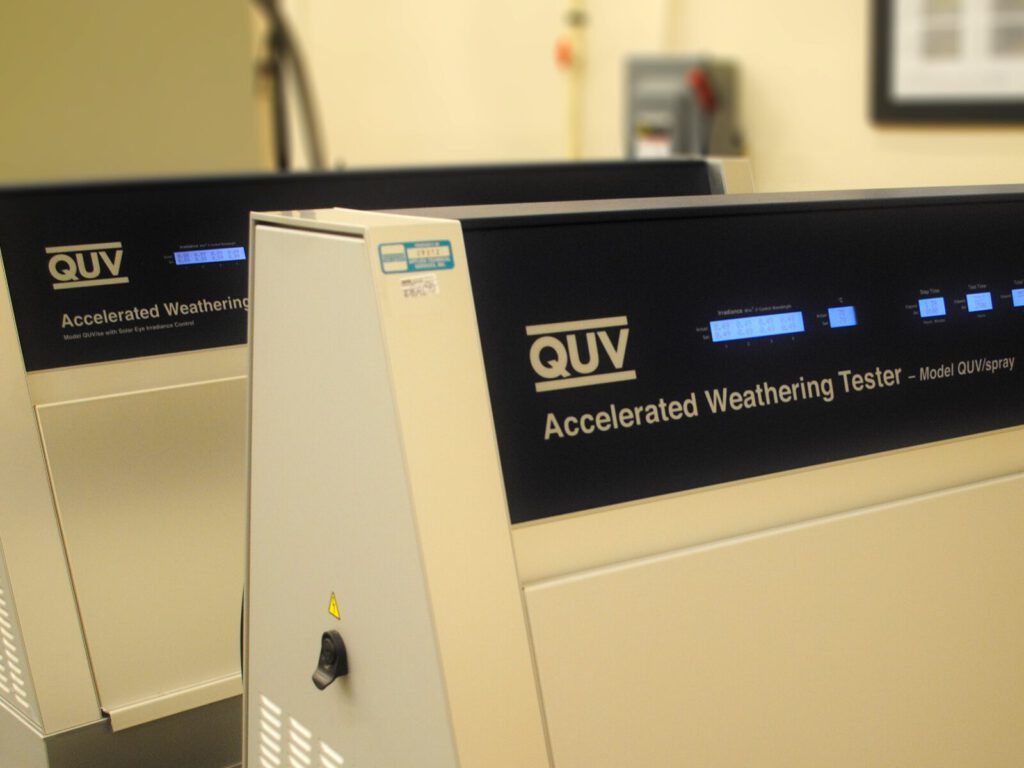

Applied Technical Services runs a fully-equipped, ISO/IEC 17025:2017 (A2LA) accredited weathering laboratory. We return relevant data quickly, whether you need it for quality control or failure analysis efforts.

Manufacturers send their products to a laboratory like Applied Technical Services to confirm or discover aspects of its physical, chemical, and thermal properties. One category of testing that our technicians perform is weathering, where they use a range of methods to establish the test sample’s resistance to damage over time from various environmental stressing factors, such as temperature, humidity and UV radiation.

This broad category of testing is broken down according to specific weathering parameters that the ATS weathering laboratory simulates during tests. Depending on the needs of the client and the intended use of the product, we may subject sample materials to one test performed to a single standard, or multiple tests each performed to their relevant standards.

The tables below reflect the methods of weathering exposure that ATS performs to their relevant, internationally-recognized standards:

Humidity/Temperature Cycling & Heat Aging Analysis

@media (max-width: 767px) {

#eael-data-table-wrapper-483f7ad.custom-responsive-option-enable .eael-data-table thead {

display: none;

}

#eael-data-table-wrapper-483f7ad.custom-responsive-option-enable .eael-data-table tbody tr td {

float: none;

clear: left;

width: 100%;

text-align: left;

display: flex;

align-items: center;

}

}

| Method | Standard |

|---|---|

| Heats test sample to proportionately age it and determine how long it lasts | BMW TS 308, IEC 68–2–30, PrV303, GM 9505P2, ISO 2440, MIL-STD 810H (Method 501, 502, 507) (A2LA Accredited) |

| Simulates climates of differing humidities and temperatures to find damage accrued over time | Also conducted to relevant industry and client standards |

UV Weathering Analysis

| Method | Standard |

|---|---|

| Used to simulate damage from the short wavelength portion of sunlight | ASTM G154, ISO 11507 (A2LA Accredited) |

Xenon Testing

| Method | Standard |

|---|---|

| Simulates one form of sunlight radiation to monitor damage accrued over time | ASTM G155, SAE J2527, SAE J1885, SAE J2412 (A2LA Accredited) and ASTM D2565, ASTM D4459, ASTM D6695, ISO 4892–2, MIL–STD–810 |

ATS’ Weathering Laboratory

For over 50 years, ATS has reliably provided testing, engineering consulting, and inspection services of unparalleled quality. We serve clients from across the world, representing an array of industries. Our experienced laboratory technicians are comfortable performing all the above mentioned methods related to weathering exposure, as well as hundreds more not listed here. We are passionate about returning the most accurate and relevant results to our clients and do so within a quick turnaround window. If you have questions or concerns about your product’s resistance to weathering, send a sample to ATS for testing – we take a closer look.