Environmental factors cause exposed metal surfaces to sustain damage from corrosion, a form of chemical deterioration, over time. Corrosion undermines the structural integrity of metal components — from screws to girders — and so it needs to be dealt with. Preferring to avoid lost production, costly repairs, and safety risks, owners of equipment and infrastructure with metal components understand the need to protect their assets. Most apply a protective coating to metal surfaces because it helps prevent corrosion. ATS’ Environmental Testing Division performs a variety of salt spray testing methods to characterize client samples’ resistance to highly corrosive environments.

ATS’ Environmental LAB Salt Spray Testing Services

Applications

- Capture Progression of Corrosion at Intervals

- Corrosion Creepage in Scratched Coatings

- Determine Coating Adhesion

- Evaluate Degree of Rusting

- Measure Degree of Coating Blistering

Methods

- Acetic Acid Salt Fog

- CASS

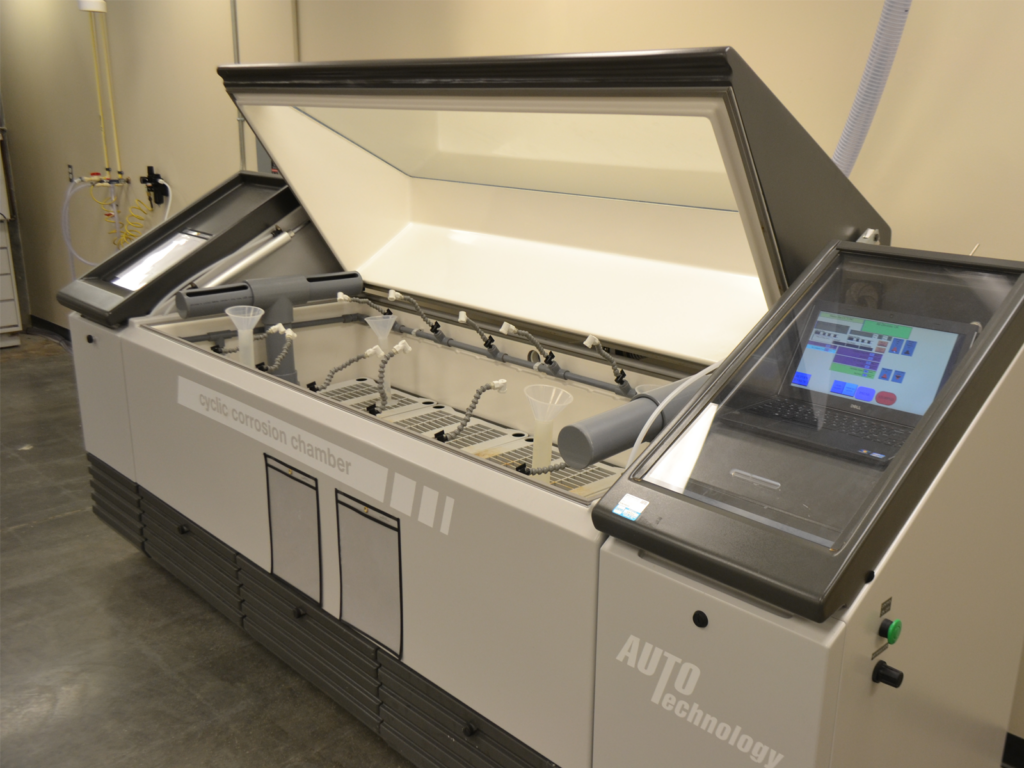

- Cyclic Corrosion

- Neutral Salt Spray

- Synthetic Seawater Fog

Standards

- ASTM B117

- ASTM B368

- ASTM G85

- ISO 9227

- MIL STD 202 Method 101