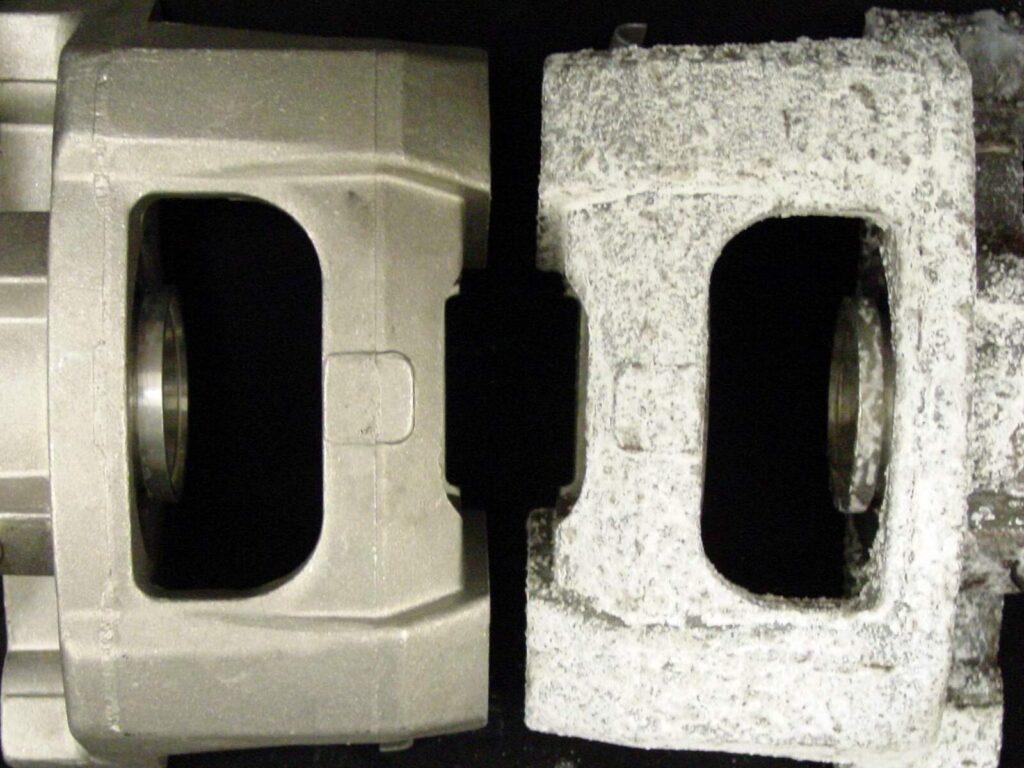

Corrosion of metals and coated metals can lead to significant damage to the structural integrity of a product.

ATS can perform accelerated salt spray exposures in accordance with a variety of specifications (ASTM B117, DIN EN ISO 9227) utilizing multiple testing chambers equipped to hold items as small as nuts, bolts, and washers, as well as larger samples, such as steel security door or the hood of a car.

In this highly corrosive environment, ATS can provide a detailed analysis of the progression of rust formation on various products and coated or plated materials.

ATS offers daily photographic evaluations, along with adhesion characteristics (creepage per ASTM D1654, blistering per ASTM D714) to determine how well a product, plating or coating system resists corrosion.