Applied Technical Services performs random vibration testing to ensure client materials perform as required by industry standards and government regulations. Product engineers must take many aspects of the final assembly’s intended service environment into account before moving beyond the design phase. One such consideration is vibration.

Vibrations occur any time forces act upon objects, causing them to oscillate at a frequency and intensity determined by several factors — including material type. Exposure to vibration over time can lead to a failure mode called fatigue, which undermines the structural integrity of the material by exacerbating existing high-stress areas into cracks and fractures. Products made with materials unsuited to withstand the vibrations present in its intended service environment stand a greater chance of failing prematurely due to fatigue.

Manufacturers realize the importance of verifying that their component materials can handle vibrations of the sort the final product must endure. They send samples of materials and components to third-party testing labs like ATS for vibration testing.

The Purpose of Random Vibration Testing

There are two primary testing schemes for vibration testing: sinusoidal and random. ATS can perform either method based on the device’s intended application. While sinusoidal testing subjects a sample to one frequency of vibration at a time (which they may use to determine the resonant frequency or induce fatigue to observe prevalent failure modes), random vibration testing exposes samples to several different vibrational frequencies at once. Doing so approximates the “background noise” endemic to nearly every service environment, as well as the forces it must survive in transit.

These vibrations may be caused by any number of sources, including the hum of a truck driving over the road as it transports the product, turbulent flow inside a pipe, rocket take-off, and hundreds of other events that product engineers must anticipate but can never exhaustively predict. These forces add up over time, comparatively quickly in the case of a poorly formulated product.

Clients may request this testing either before production to validate their designs or after to assess the finished product’s life expectancy. Whichever case brings them to our lab, ATS’ environmental testing division uses random vibration testing to determine a product or component’s resistance to damage from the unpredictable forces constantly acting on it.

General Procedures

Setting the parameters of the test correctly determines the quality of the results. The test is designed so that only those vibrations within the frequency and strength ranges set by the technicians are applied, allowing them to meet the requirements of the target procedure. The graphs below represent the vibrations being introduced to a sample as both an acceleration waveform (showing the acceleration applied at different times across the testing period) and an acceleration spectral density plot (showing the acceleration applied across each frequency tested).

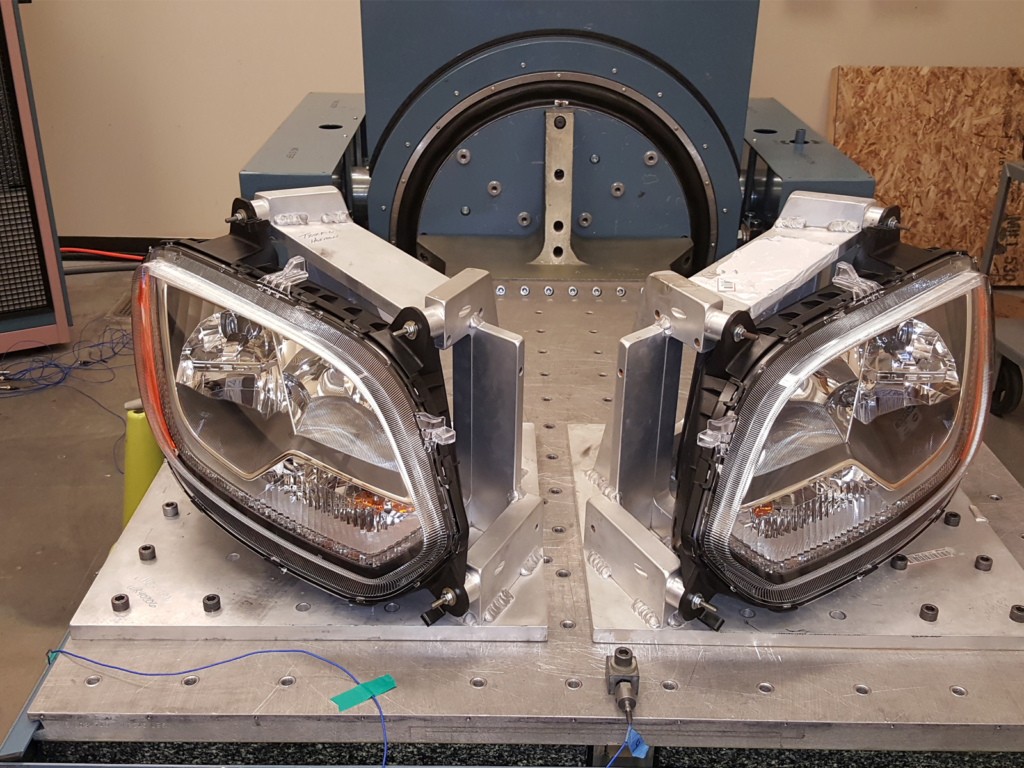

The testing process begins by securing the sample to the equipment using custom test fixtures. ATS’ in-house machining shop fabricates our test fixtures to help ensure that we achieve quality results expeditiously. Before performing the test on the sample itself, our technicians will ensure the fixture does not have a resonance frequency within the range set for the test. Once it is validated that the fixture is appropriate to the scope, testing may start in earnest.

Vibration Testing Labs

ATS’ vibration testing labs house a collection of electrodynamic shaker tables. This advanced equipment allows our technicians to apply precisely controlled vibrations to the sample. Our units can produce up to 12,000 pounds of force in a range from 5 to 2,000Hz to provide for the most rigorous testing needs. Furthermore, attachable AGREE chambers allow the environmental testing division to introduce temperature variations for combined testing.

Commonly Used Standards

While clients most often request custom specifications tailored to their particular sample, our vibration testing lab also regularly performs random vibration testing to a variety of standards, including the following for which we maintain an ISO/IEC 17025:2017 accreditation through the A2LA:

- MIL-STD 810H (Method 514)

- RTCA DO 160

- IEC 60068-2-64

Other Vibration Methods

Depending on the component or application, random vibration may not be the best fit for the client’s testing needs. Our environmental testing division performs many other methods to ensure that we can provide for virtually all types of vibration testing requirements, whether to meet quality assurance, failure analysis, or regulation compliance goals.

Here’s a list of ATS’ other vibration testing capabilities:

- Sinusoidal Vibration

- Resonance Search and Dwell

- Sine-on-Random Vibration

- Rough Handling

- Field Data Acquisition

- Shock

- Shock Response Spectrum (SRS)

- Classic, Drop, and Tumble

- Seismic Testing

- Earthquake Simulation

About ATS

Applied Technical Services, Inc. provides testing, inspection, and consulting engineering capabilities of excellent quality to clients operating around the world. In the 50+ years since our 1967 founding, our company has enjoyed booming growth. No longer a small team of three engineers serving local businesses from our founder’s basement, ATS now comprises a multidisciplinary firm that employs over 1,000 technicians, scientists, chemists, calibrators, trainers, Professional Engineers, inspectors, and investigators to answer the needs of clients from a variety of industries.

Of the many we serve, the industries that most benefit from our capacity as a vibration testing specialist include the following:

- Aerospace

- Automotive

- Communications

- Consumer Products

- Defense / Military

- Healthcare / Medical

- Insurance / Legal

- Manufacturing

- Nuclear

- Oil / Gas

How We Prioritize Quality

The ATS environmental testing division conducts all their testing in accordance with our quality assurance program. Our Marietta lab, where they perform all our random vibration testing services, maintains ISO 9001:2015 registration. We earned this distinction by upholding a quality management system audited by ISO-approved inspectors. These specialists affirm that our procedures conform to the internationally recognized standard outlining effective quality assurance practices. By closely aligning ourselves with these principles, ATS ensures accountability for the quality of services we provide and promotes an environment where we may continually improve that quality.

To ensure clients enjoy the best customer experience we can deliver, ATS maintains the following policies:

- Our lab experts return clear, accurate, and detailed reporting within a short turnaround window

- Customer service representatives facilitate prompt contact with relevant testing personnel when clients reach out with questions

- These testing specialists stay accessible to client outreach, responsive to their needs, and engaged while helping secure a solution to their problem

If your company needs random vibration testing from an accomplished provider, contact ATS today for a free quote — We take a closer look.