Less than five percent of sunlight consists of UV radiation. While this seems like a small amount, UV radiation from the sun causes significant damage over time. Materials like plastics, coatings, and textiles may fade, crack, peel, or change color depending on how sensitive they are to UV rays. Even materials designed to withstand direct exposure to sunlight can sustain damage that compromises their integrity.

UV stability testing is a method of accelerated weathering that reproduces the effects of long-term exposure to sunlight in a more time-efficient manner. This kind of testing exposes sample materials to UV light and high temperatures, either cyclically or statically, and may include exposure to moisture to assist in simulating real outdoor service conditions. Testing a material’s resistance to UV damage helps manufacturers meet production standards and develop long-lasting products.

Methods of UV Stability Testing

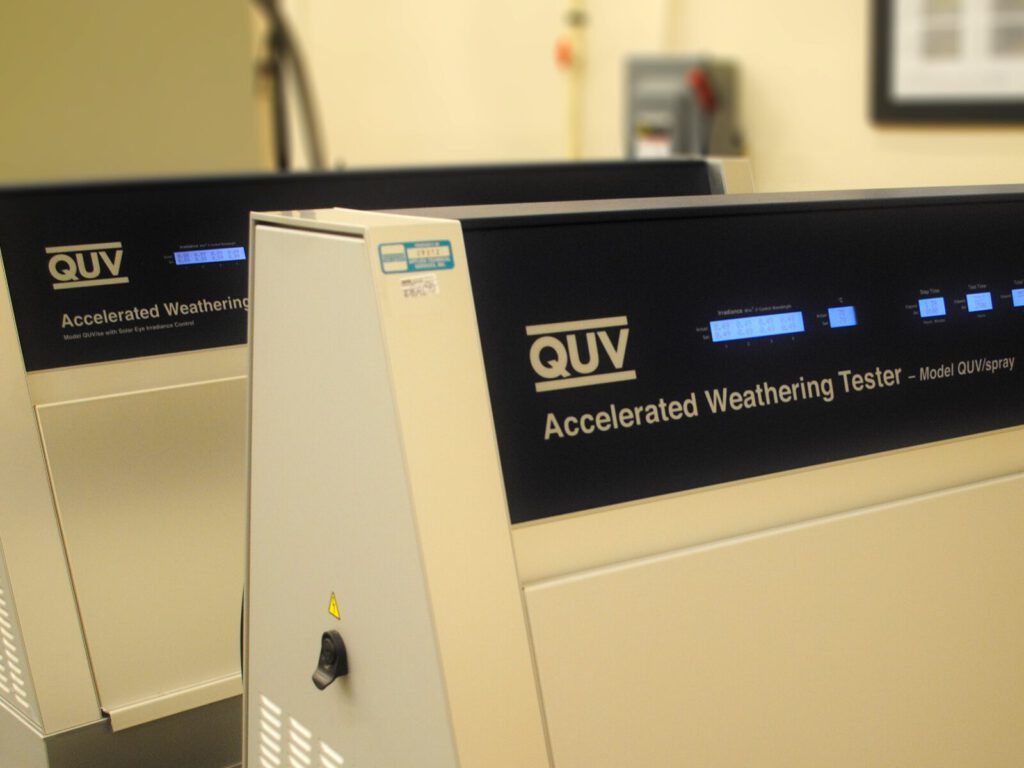

UV stability can be tested according to many standards and using several different methods. One of the most widely used UV testers is the QUV. The QUV weathering tester uses fluorescent UV lighting, condensation, temperature control, and water spray to simulate accelerated weathering. The QUV rapidly accelerates the aging process of test materials, showing what years’ worth of damage may look like in only a few days or weeks.

Some standards that ATS tests using the QUV are:

- ASTM D4329

- ASTM D4587

- ASTM D4674

- ASTM D5894

- ASTM G154

- SAE J2020

Another way to test UV stability is using xenon arc weathering. Xenon arc testers generate visible, UV, and infrared light, allowing them to closely replicate natural sunlight. Using different filters over the lights adjusts the heat and levels of radiation to achieve the desired effect. Xenon testers, similarly to the QUV, may also use humidity or water spray to simulate outdoor weathering conditions. Some of the many standards that ATS tests using xenon arc exposure are:

Choose ATS for UV Stability Testing

At Applied Technical Services, we aim to build an environment of excellence. Since 1967, we have offered an expanding range of materials testing services. We employ skilled professionals dedicated to providing an outstanding customer experience. Our technicians can conduct customized UV stability tests according to your specifications and report back with clear, quantified results. We operate within a quick turnaround window to help you make timely, informed decisions about your product.

When it comes to UV stability testing, ATS can help.