Materials and coatings’ performance can deteriorate under the combined effects of solar UV radiation, temperature and moisture. Applied Technical Services performs UV weathering to determine client products’ resistance to solar radiation, temperature, and moisture.

Purpose and Benefits of UV Weathering

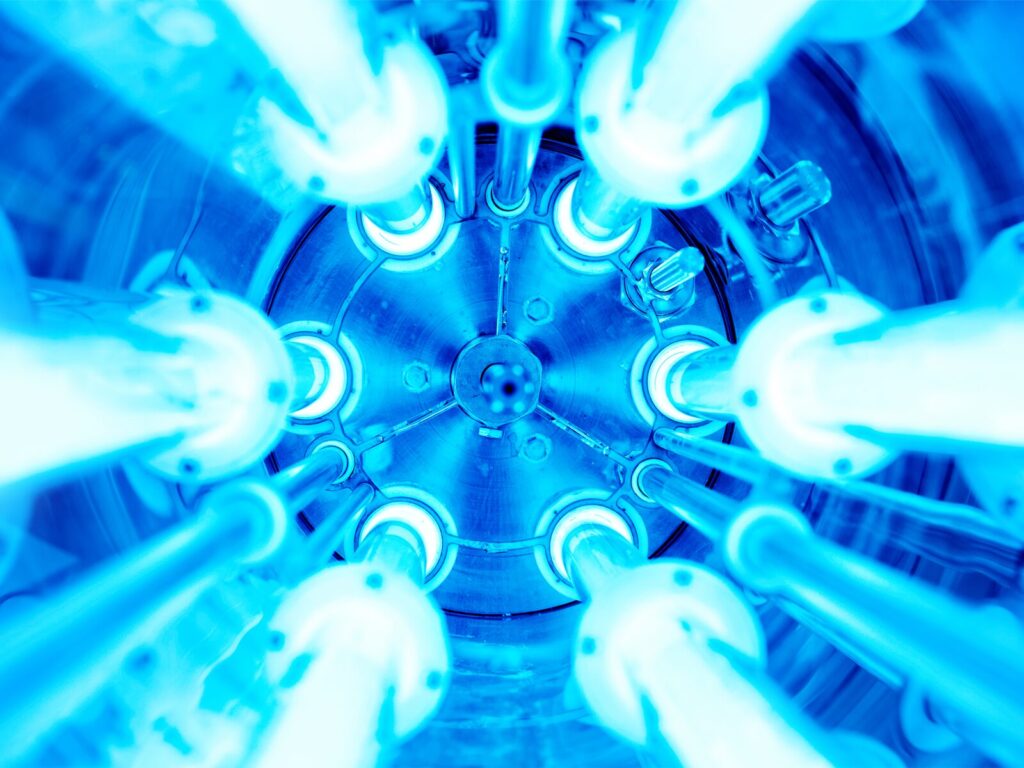

ATS has the capacity to perform accelerated weathering testing through the use of fluorescent UV chambers. This technique simulates the effects of sunlight in the short wavelength portion of the solar spectrum.

Whether the evaluation criteria is based on visual properties (color change, gloss, haze, optical transmission) or structural properties (impact resistance, tensile strength, abrasion), ATS has the capabilities to simulate a wide variety of weathering applications and requirements and conduct the subsequent performance tests.

Our Environmental Testing Chambers

ATS’ chambers offer controlled conditions of temperature, condensation and duty cycle of the sunlight exposure, all captured in a digital format. Standard specimens are 3”x6” and should be flat, however other dimensions can be tested.

The environmental testing lab is ISO/IEC 17025:2017 (A2LA) accredited to perform UV weathering to its internationally recognized standards of ASTM G154 and ISO 11507.