American Society for Testing and Materials

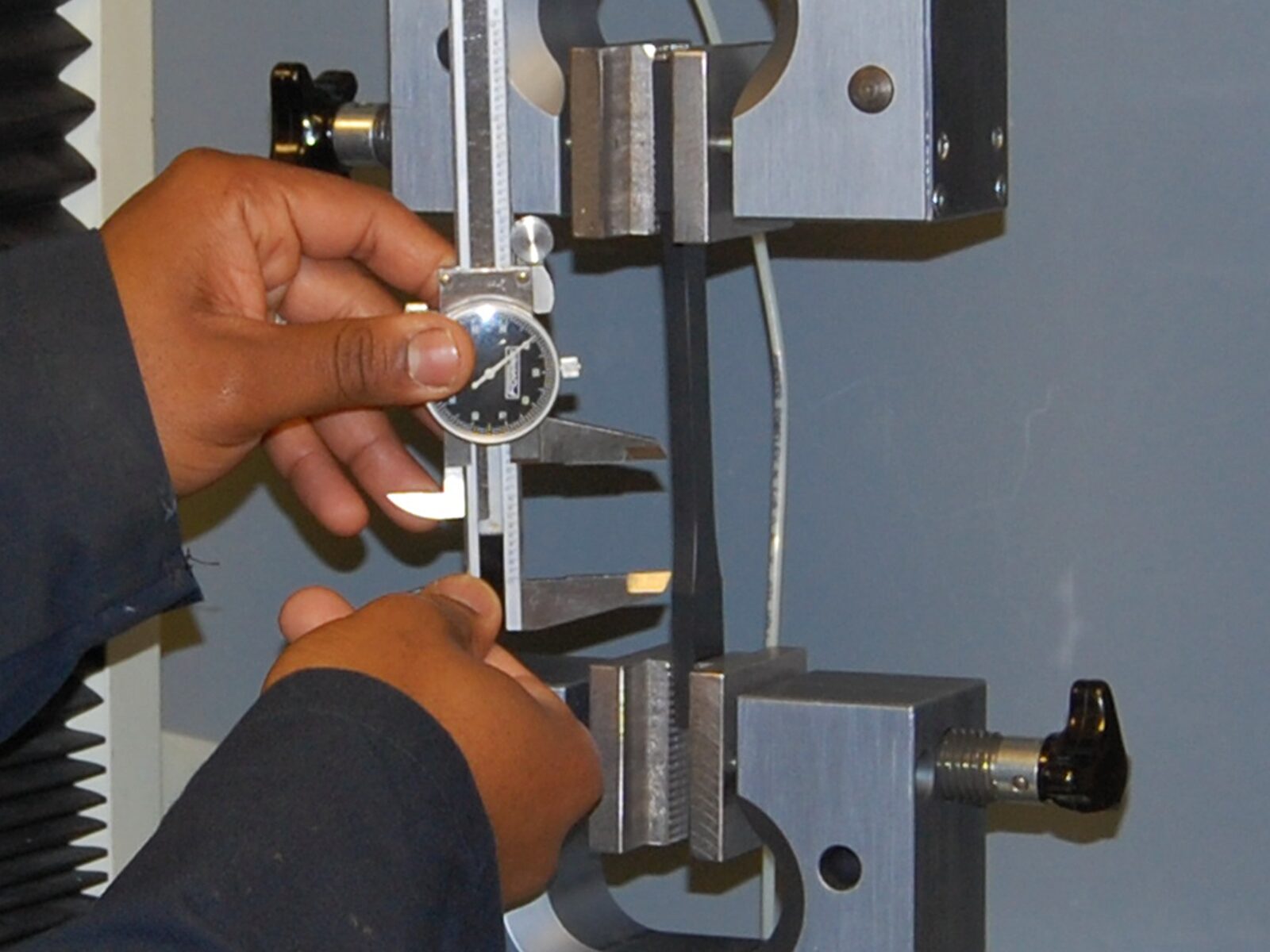

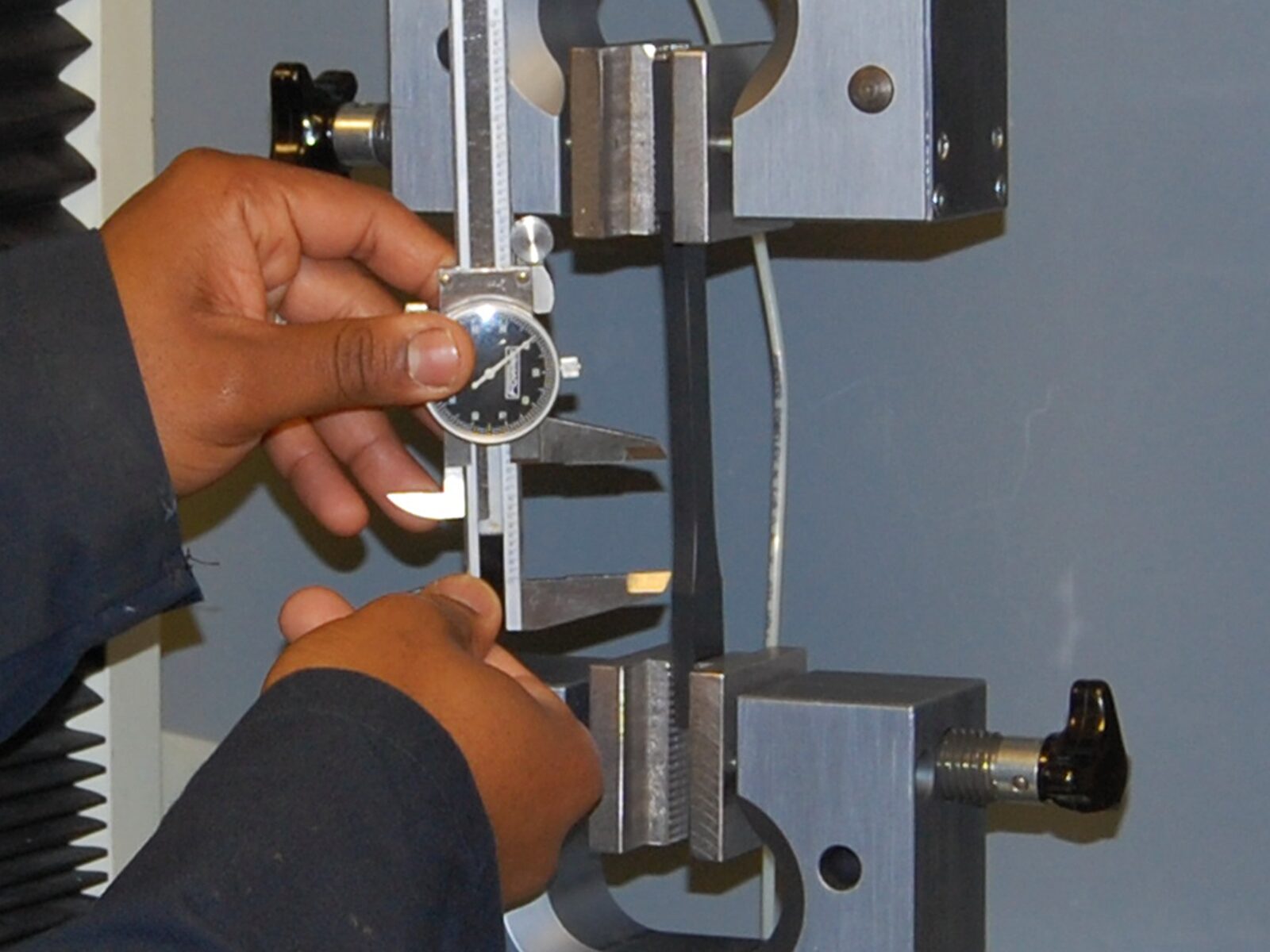

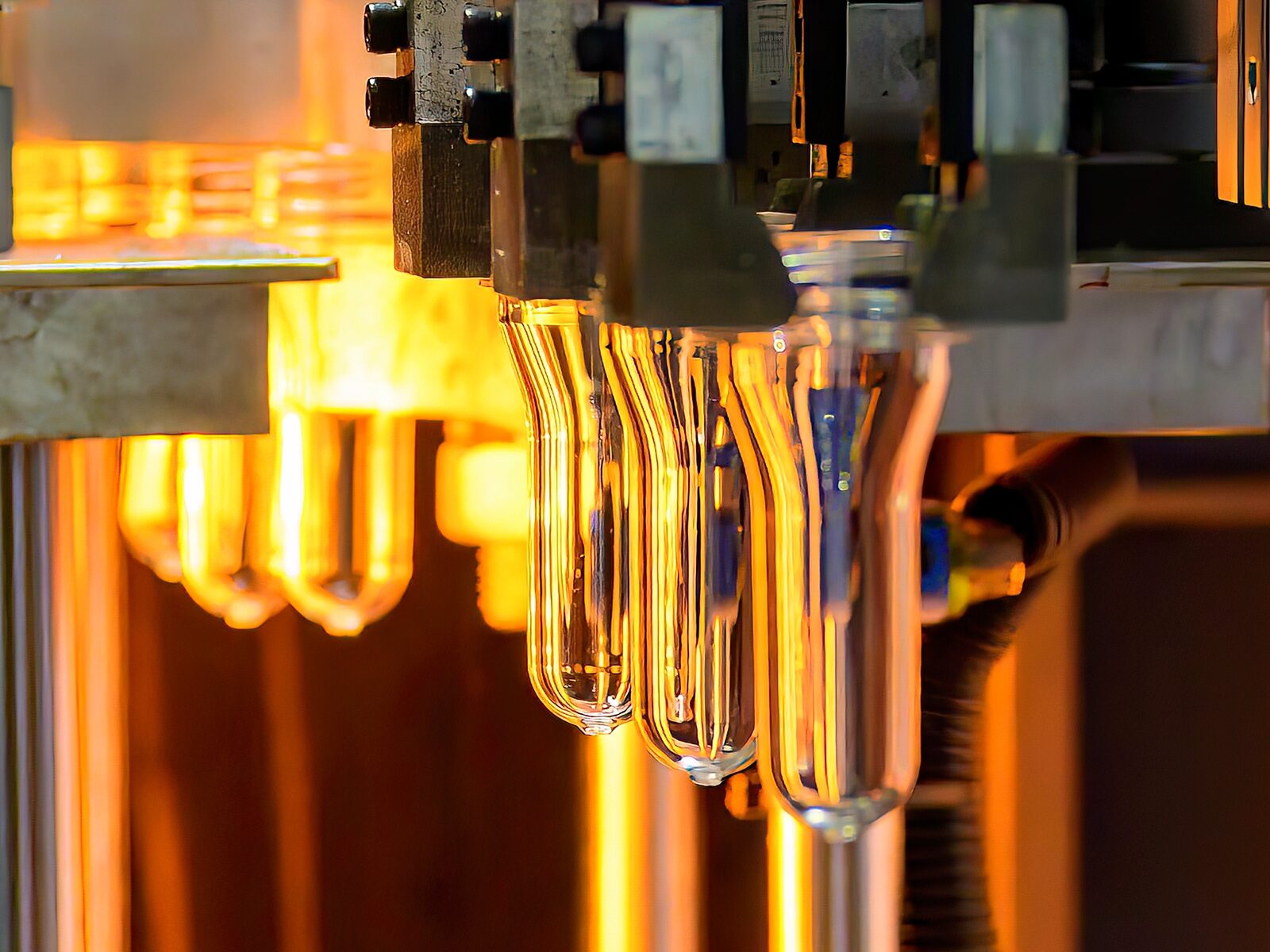

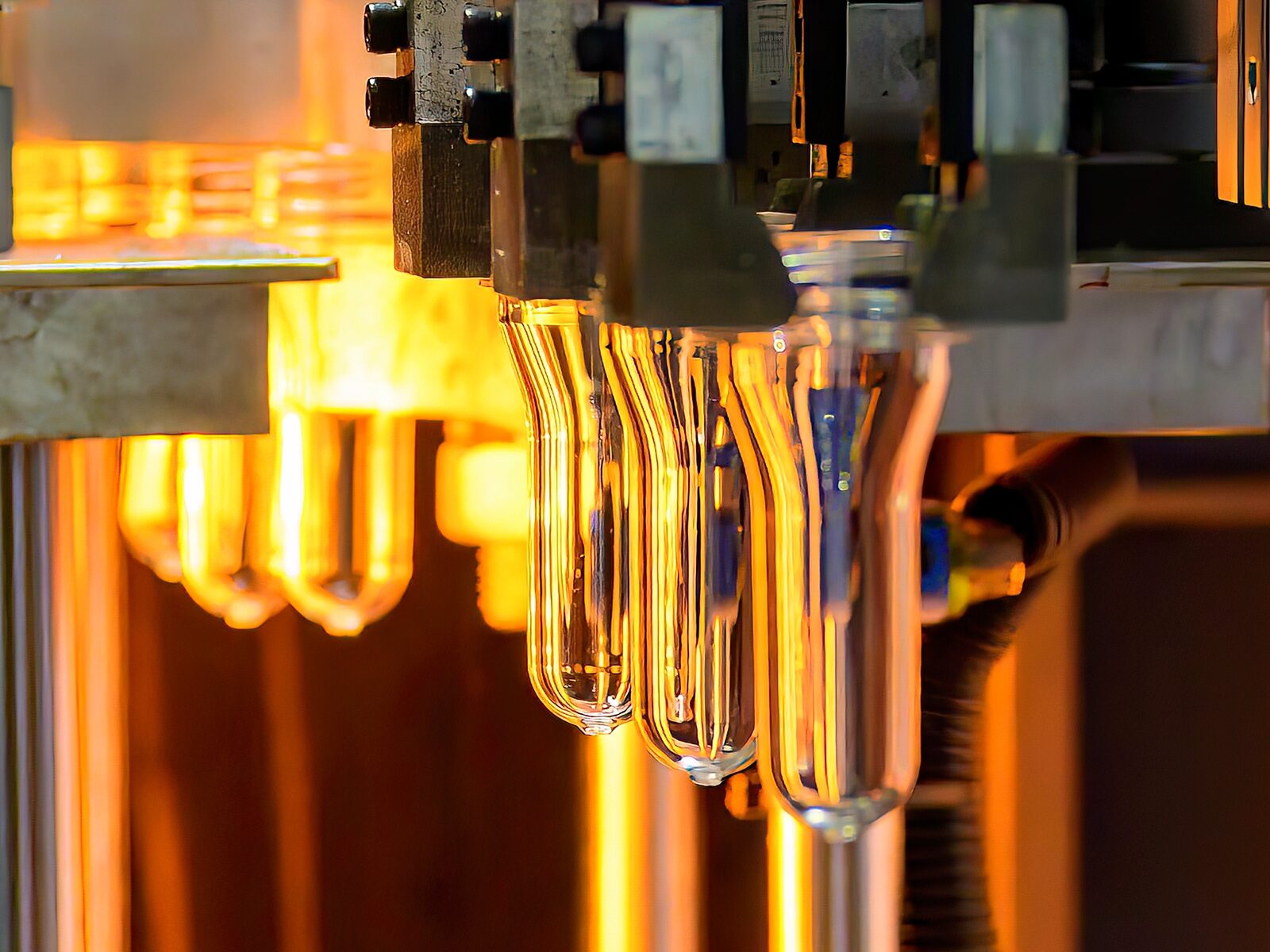

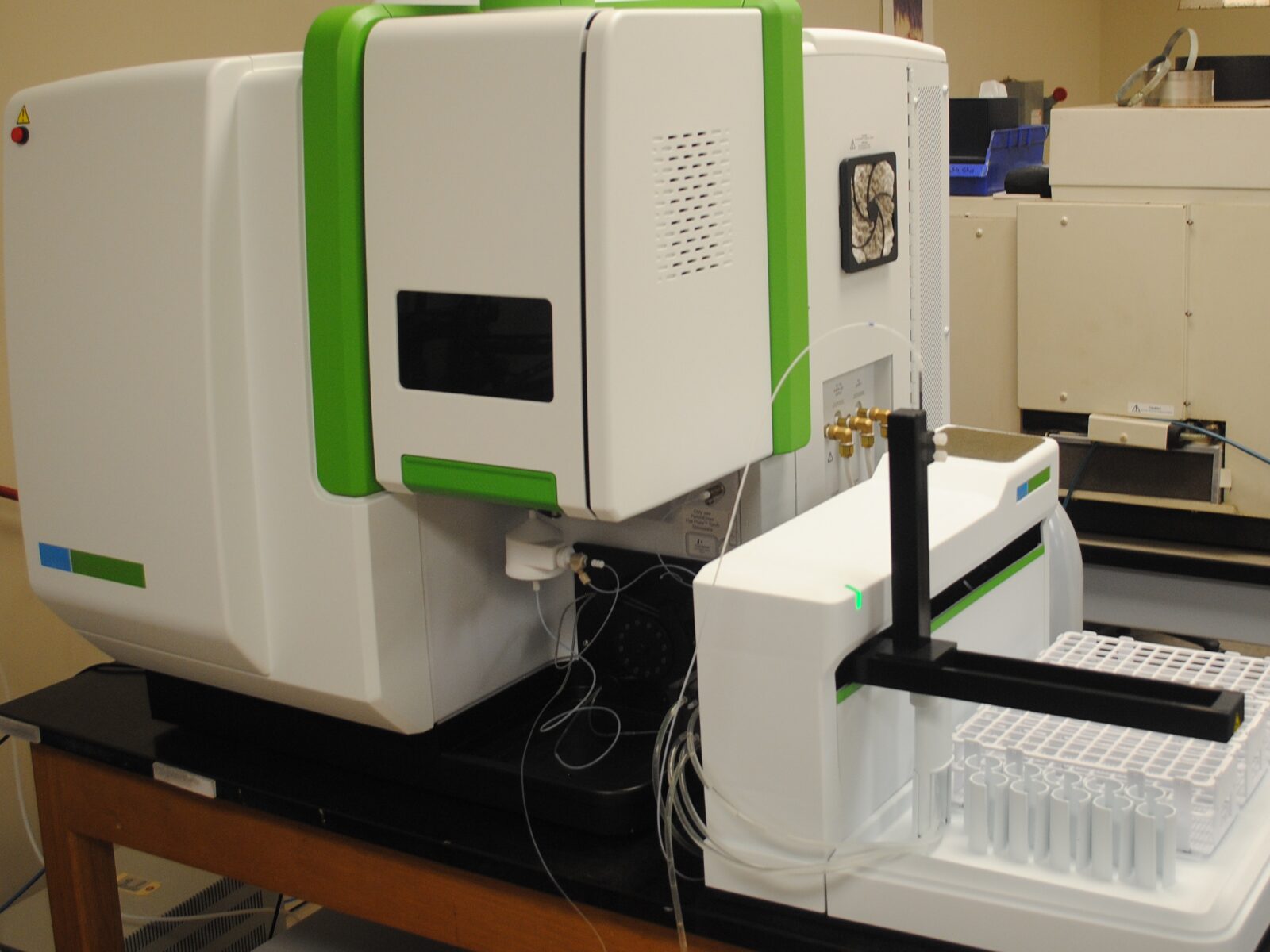

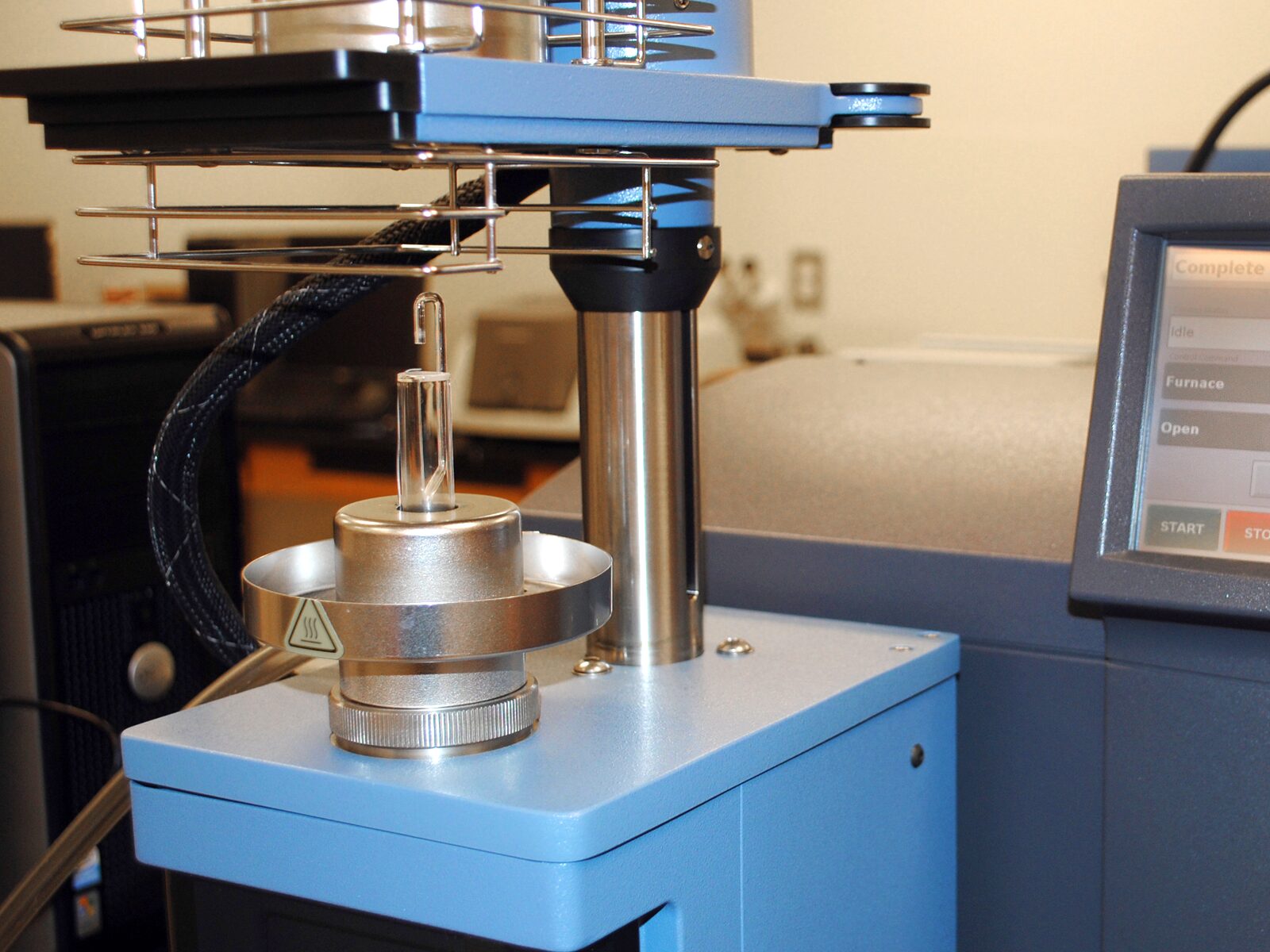

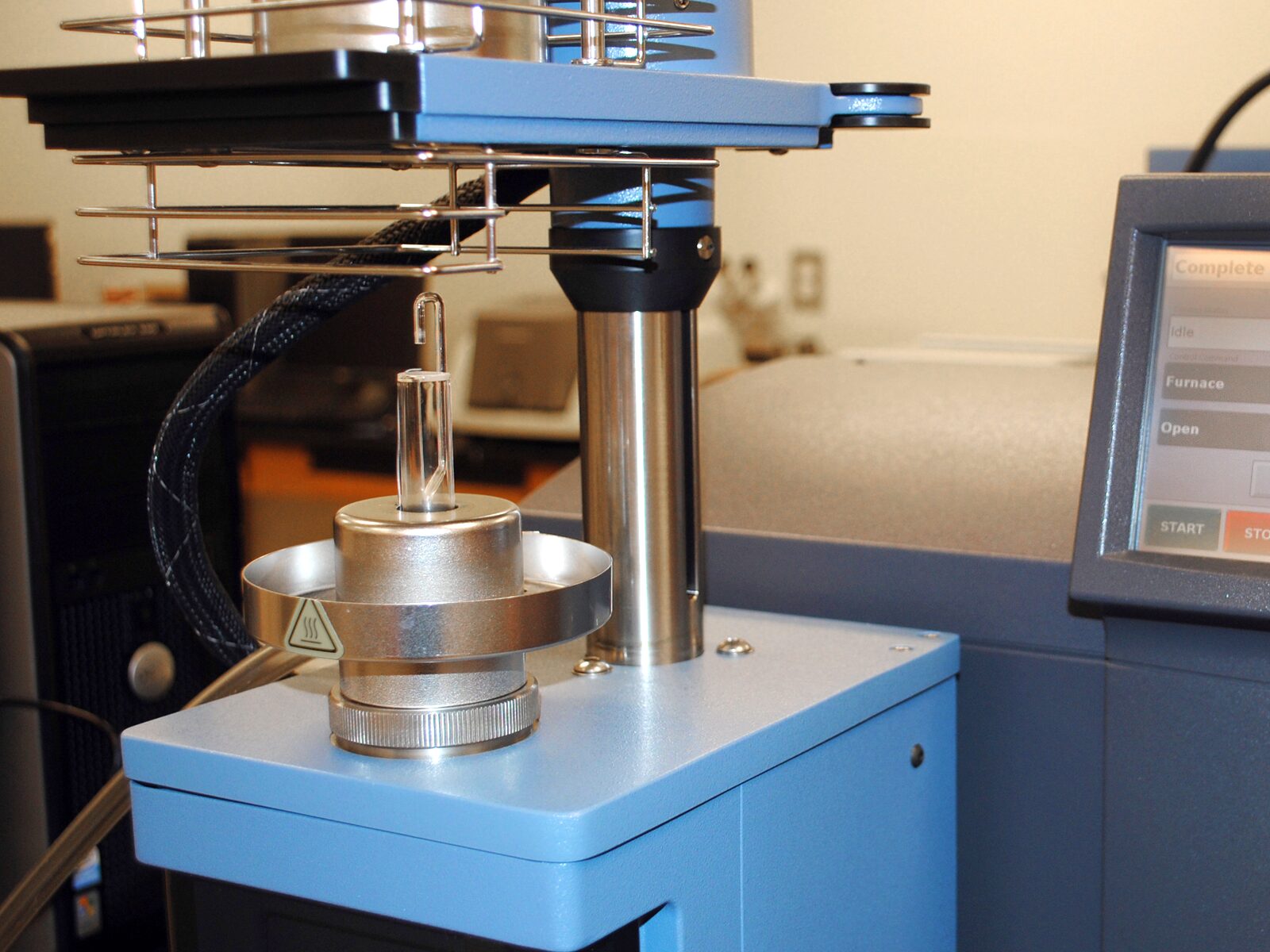

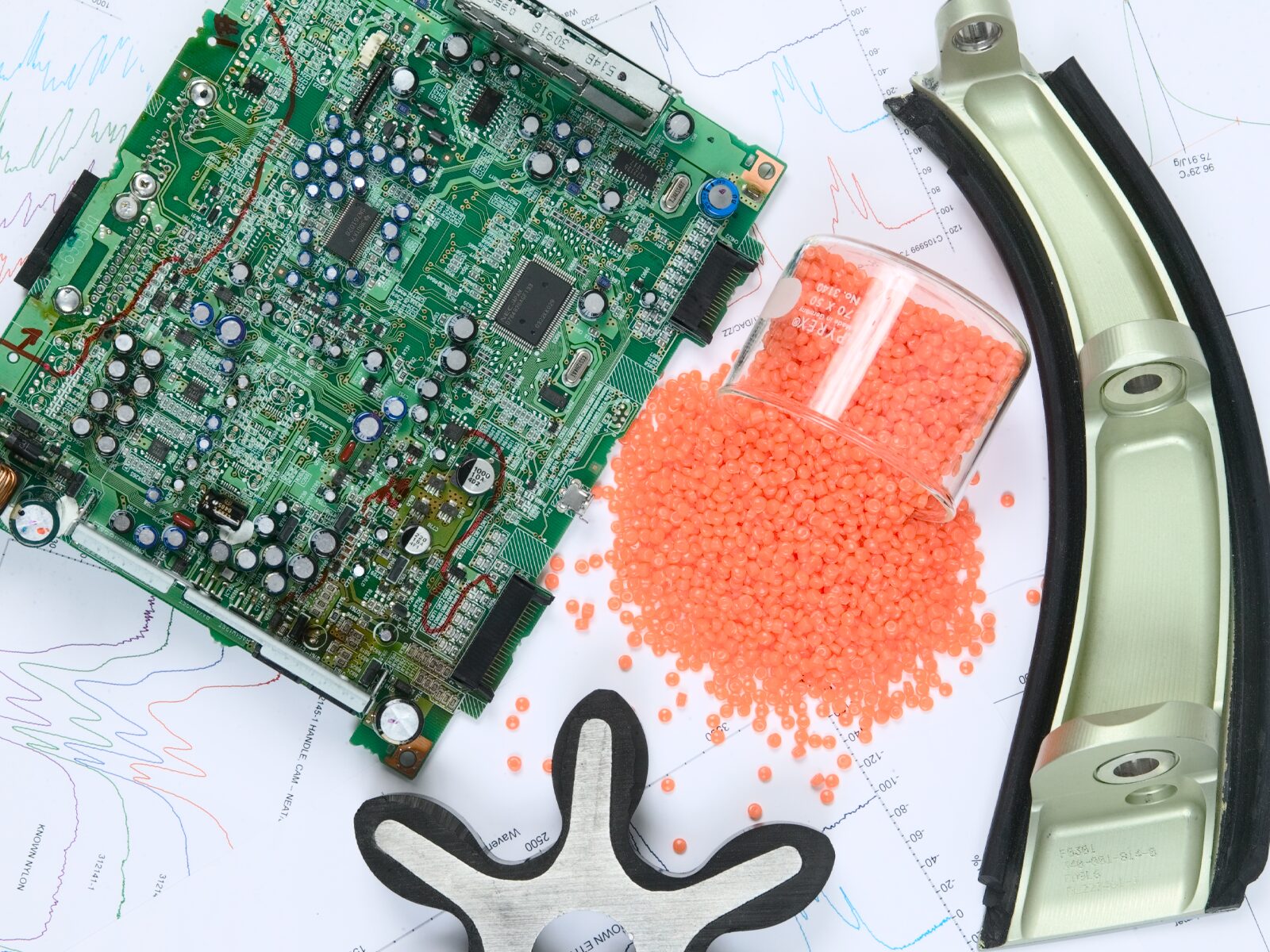

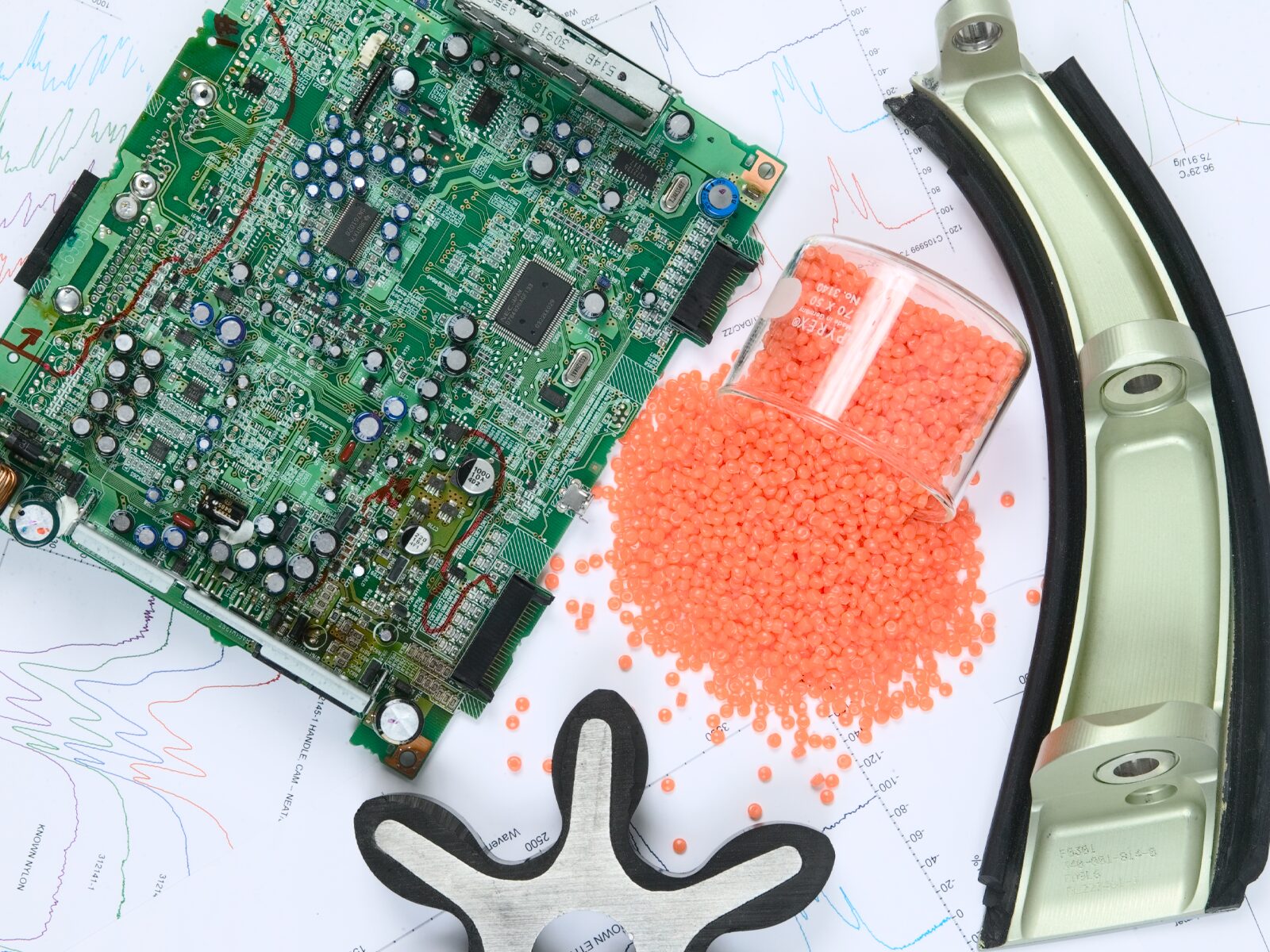

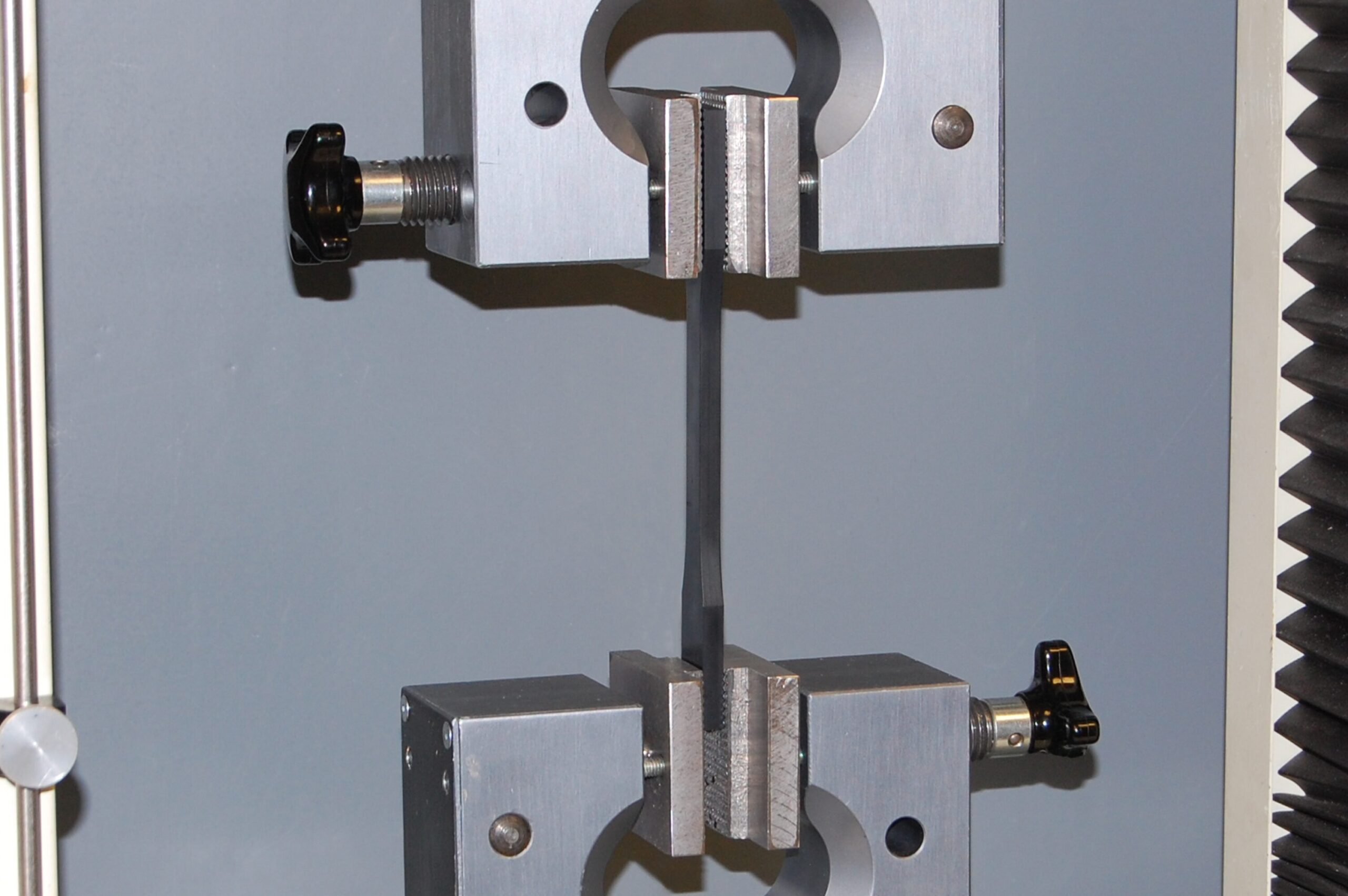

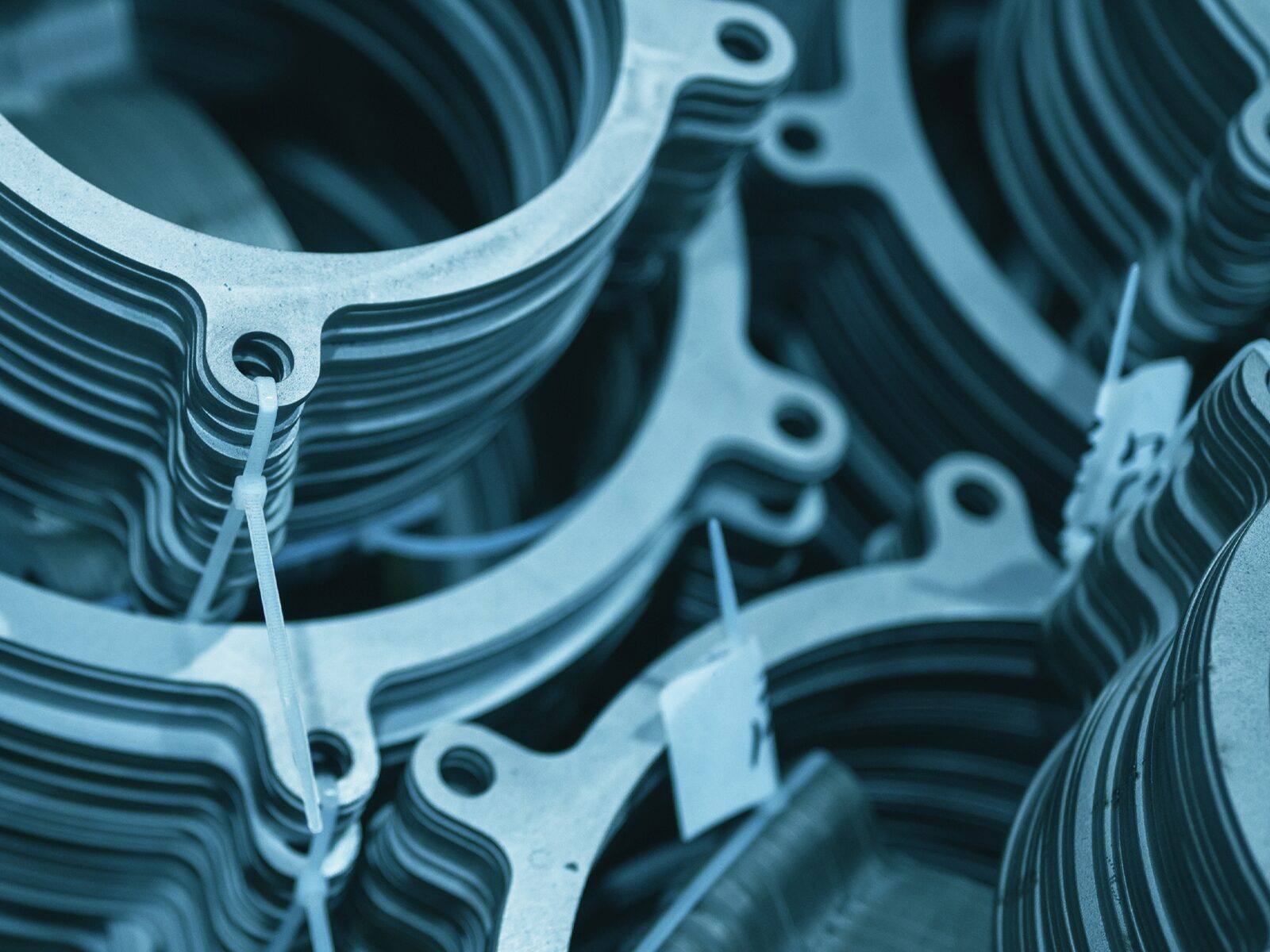

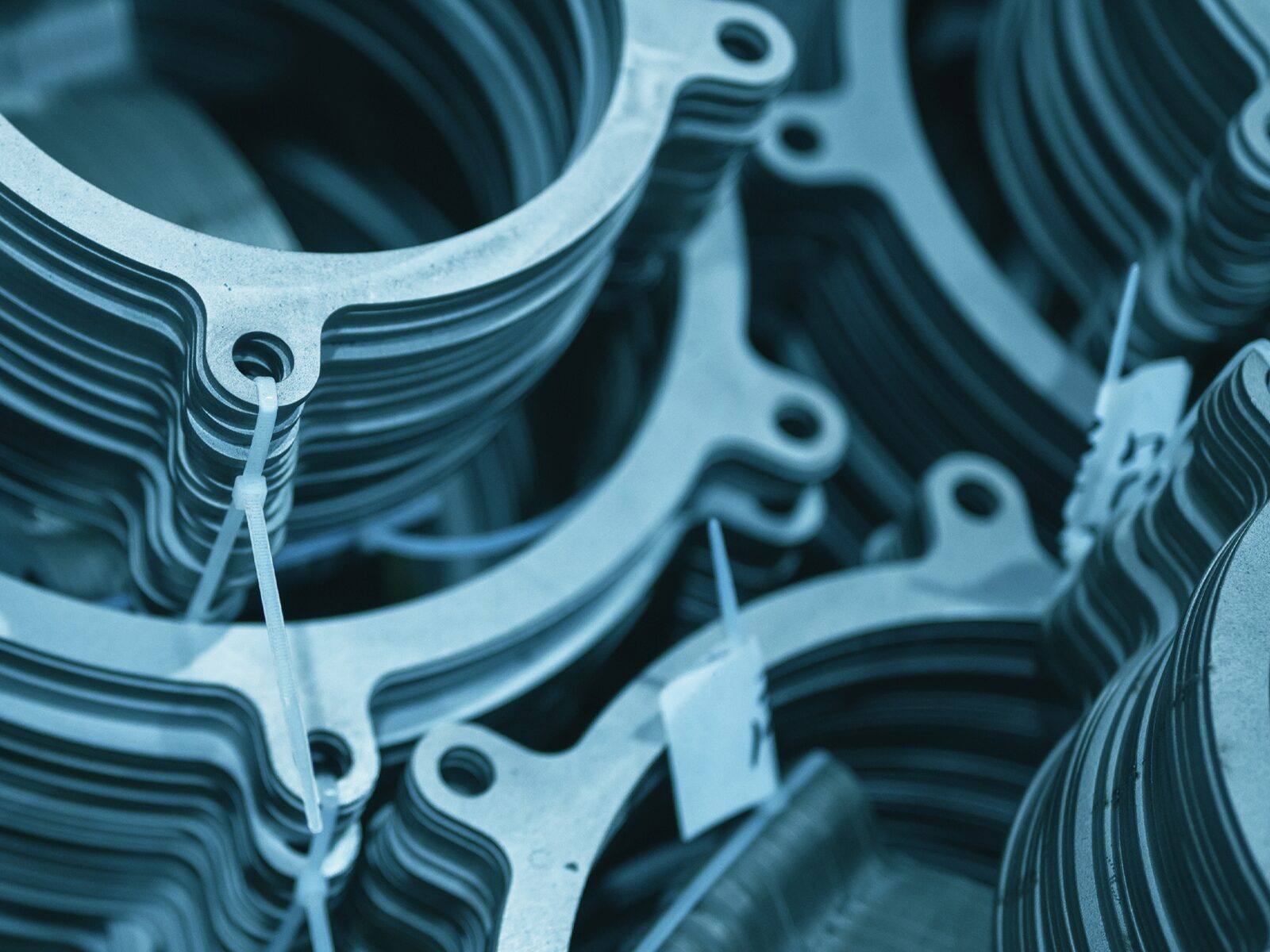

Applied Technical Services performs ASTM certified tests for all industries. From salt spray testing to adhesion, our labs are qualified to meet American Society for Testing and Materials Standards.

ASTM B368

ASTM D1177

ASTM D1218

ASTM D1238

ASTM D2240

ASTM D3039

ASTM D3418

ASTM D4065

ASTM D618

ASTM D638

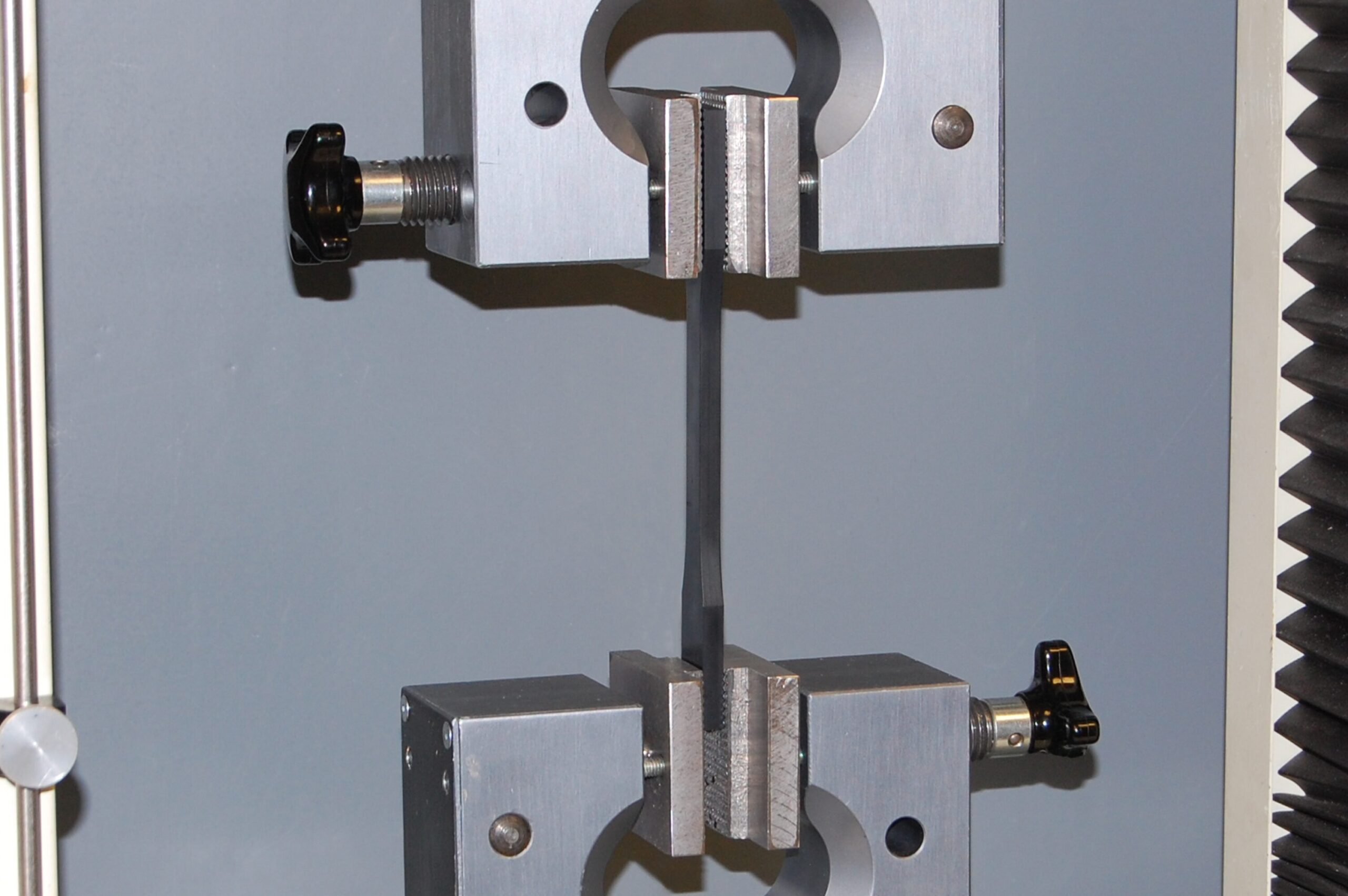

ASTM D882

ASTM D732

ASTM D785

ASTM D5023

ASTM D5026

ASTM D5296

ASTM D5865

ASTM D6869

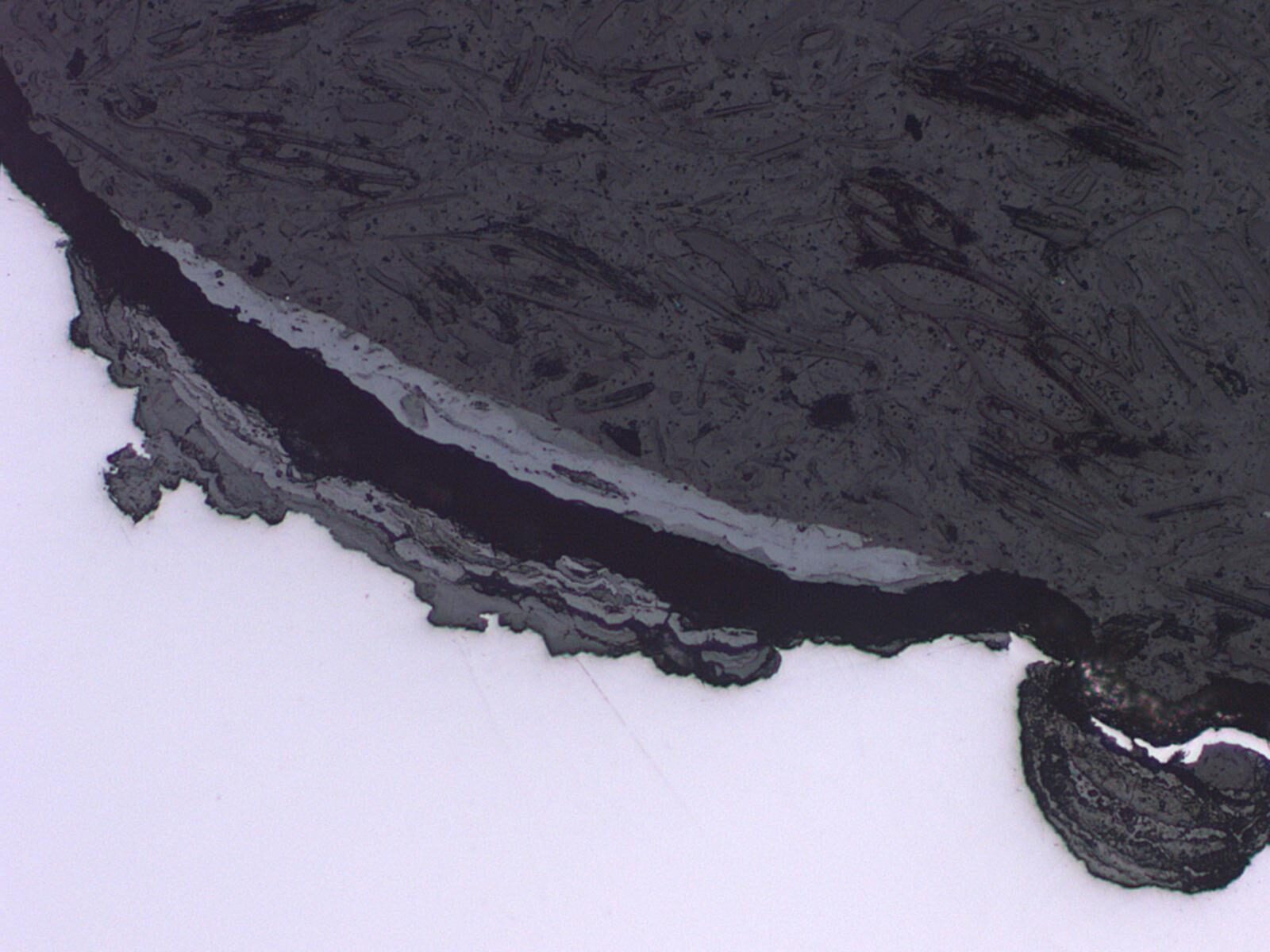

ASTM E399

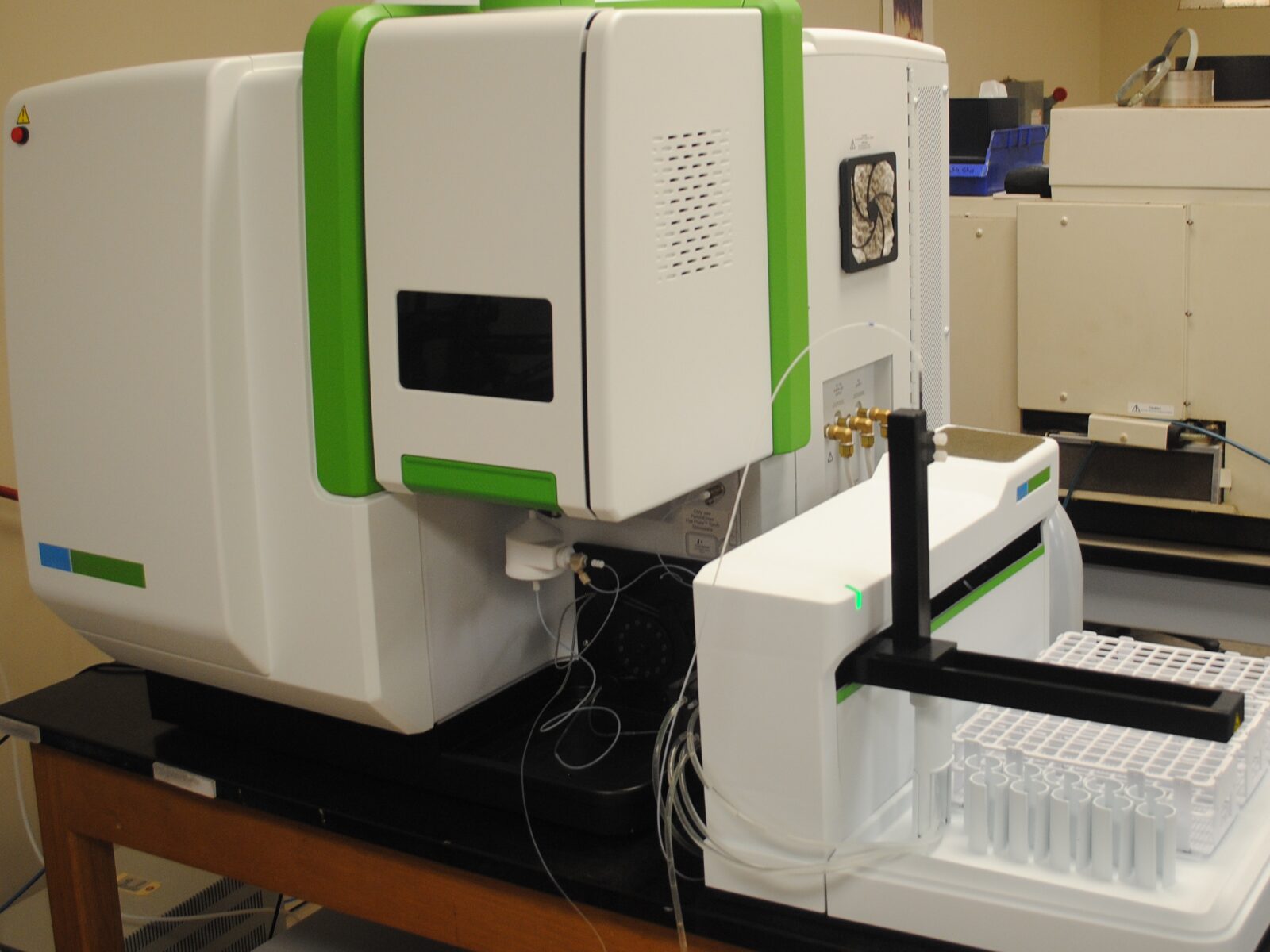

ASTM E415

ASTM E466

ASTM E831

ASTM E1086

ASTM E1251

ASTM E1479

ASTM E1545

ASTM E2092

ASTM E647

ASTM F963-11

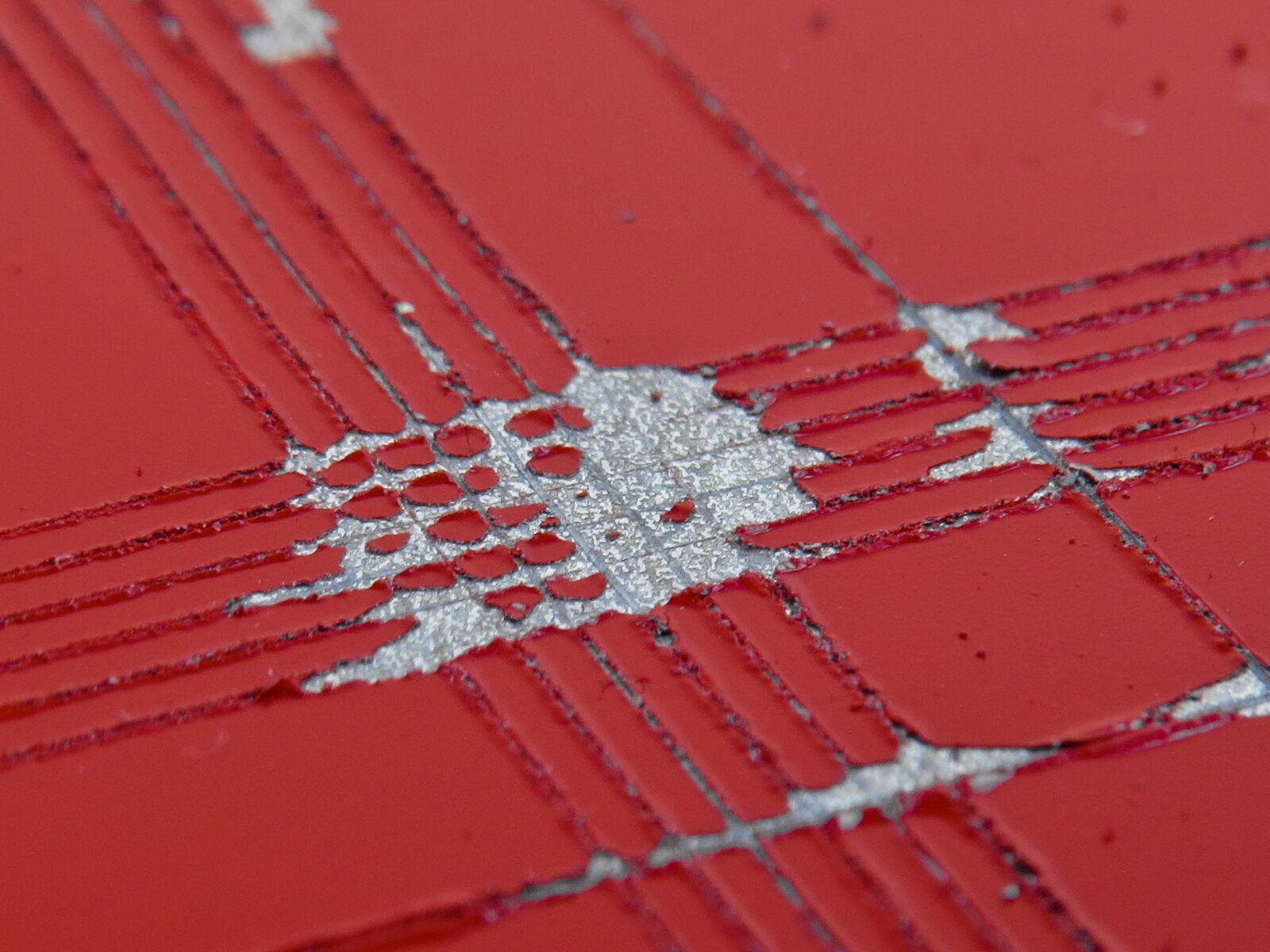

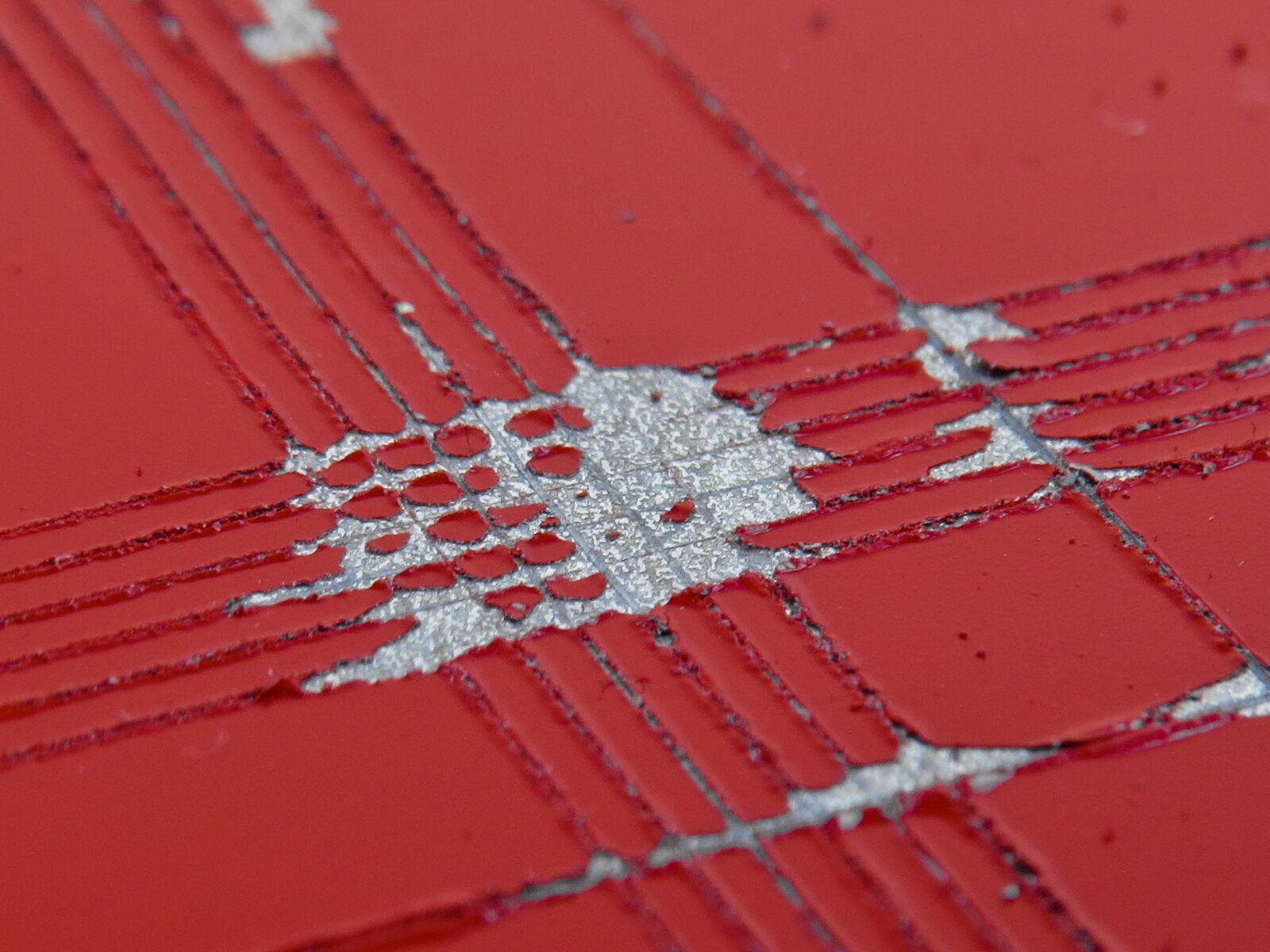

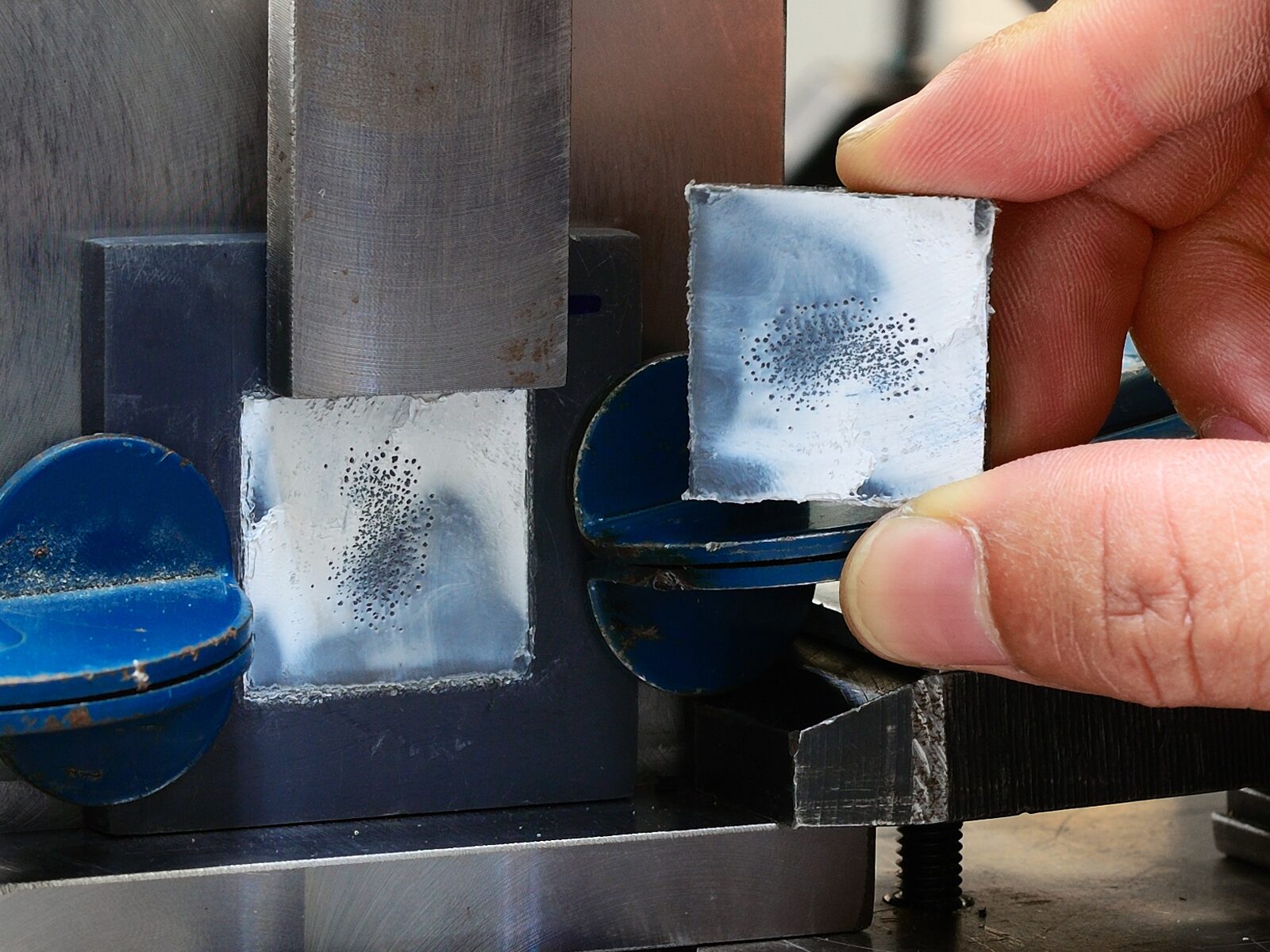

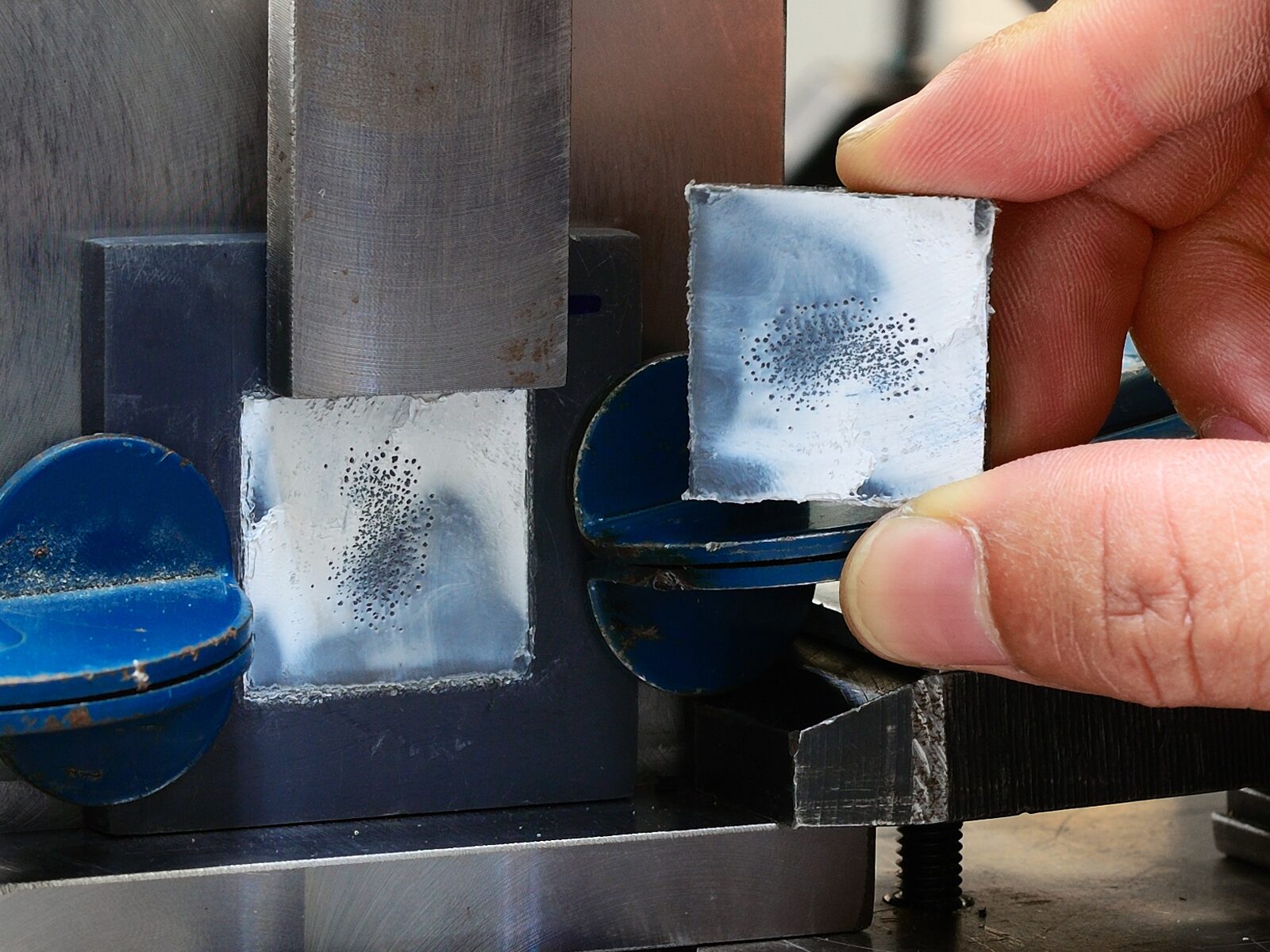

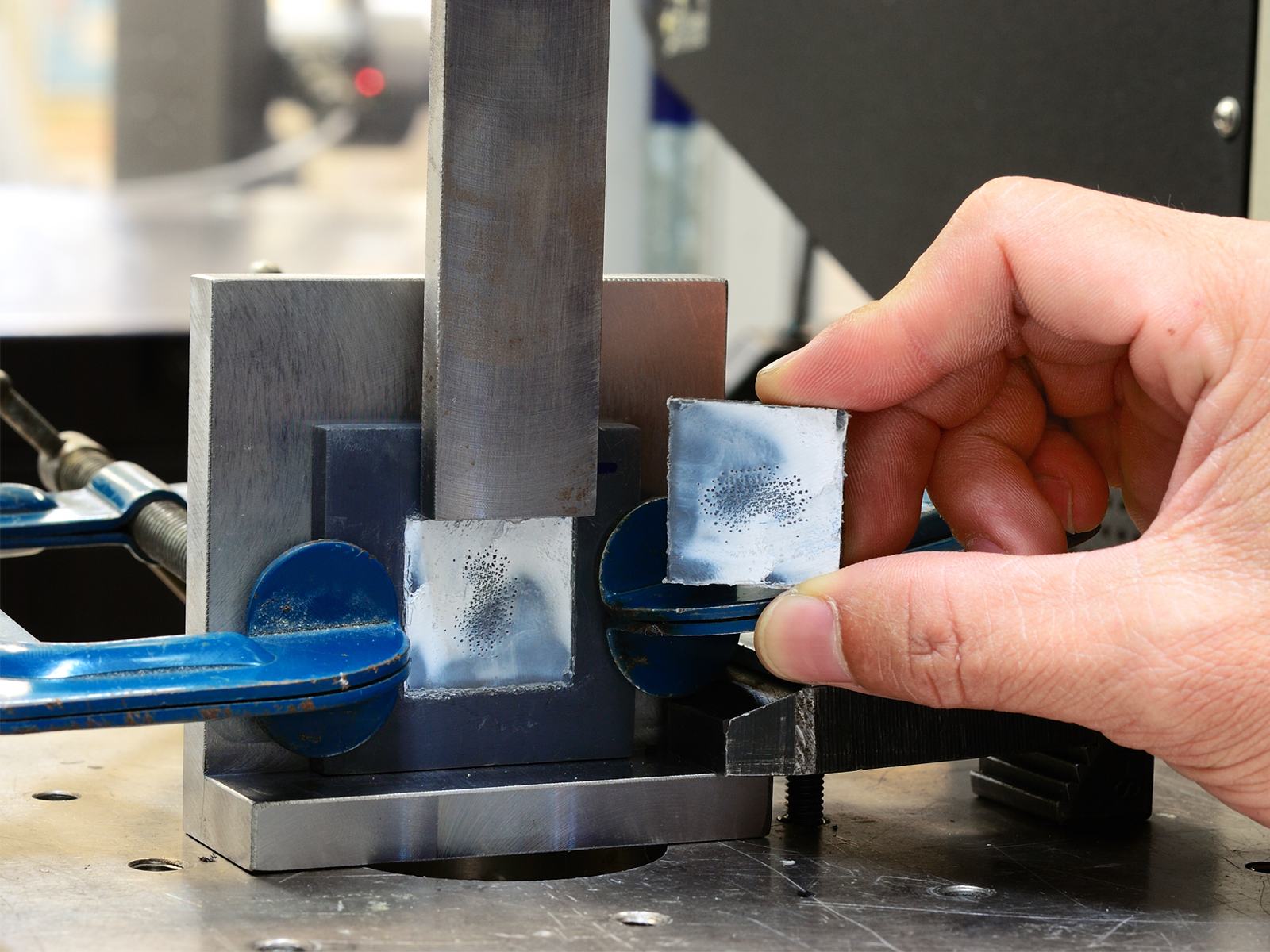

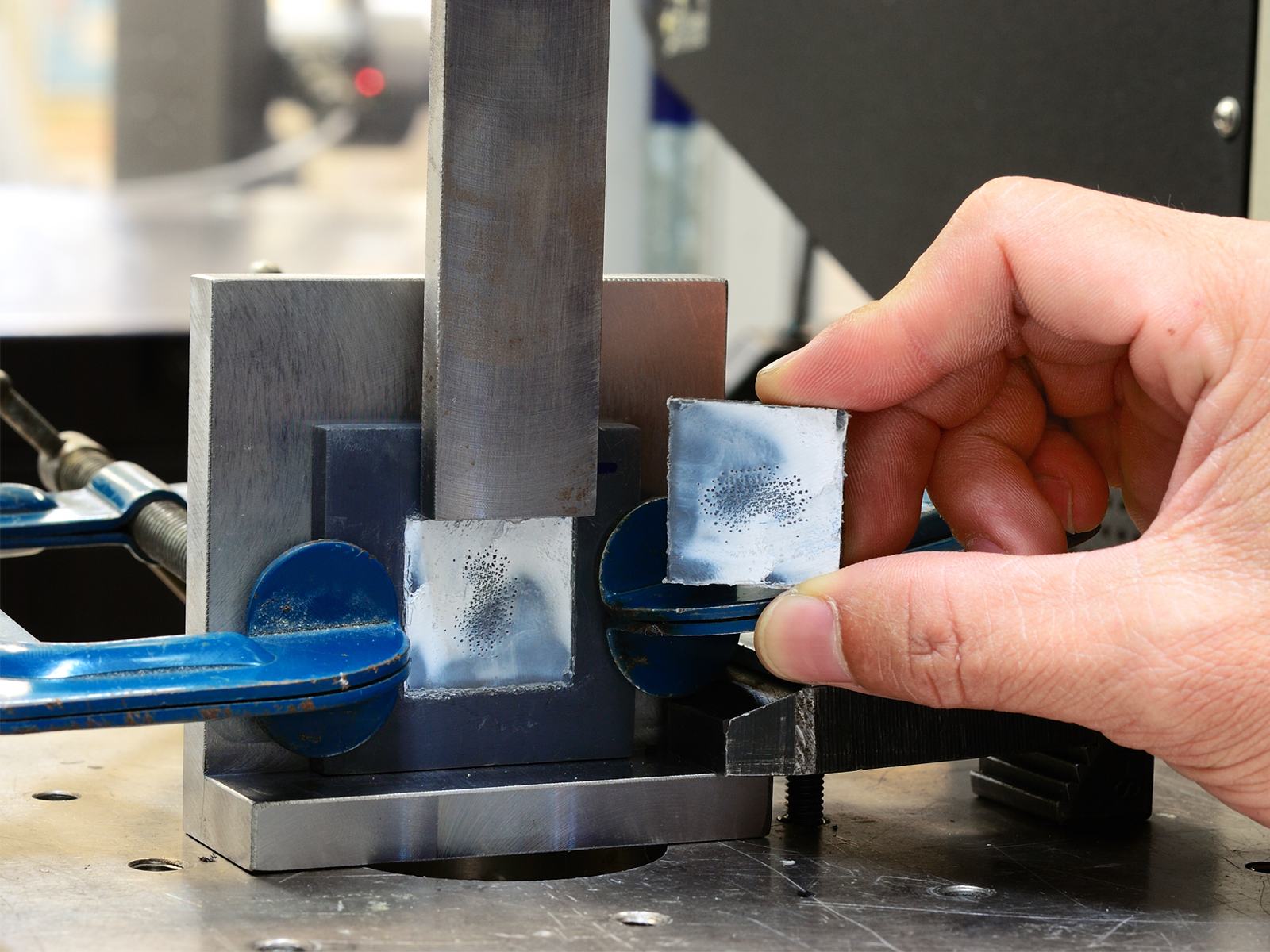

ASTM Coating Adhesion Testing

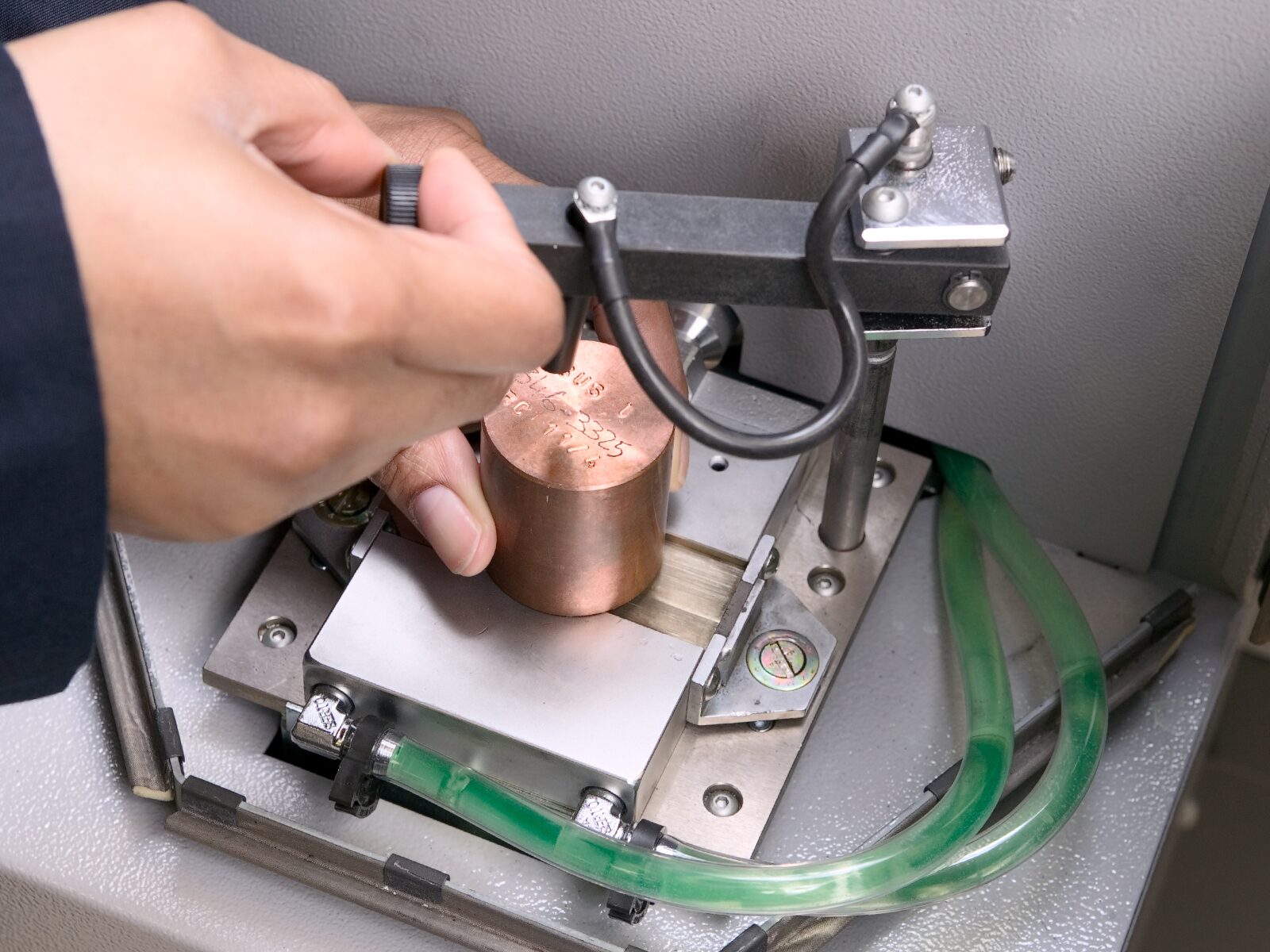

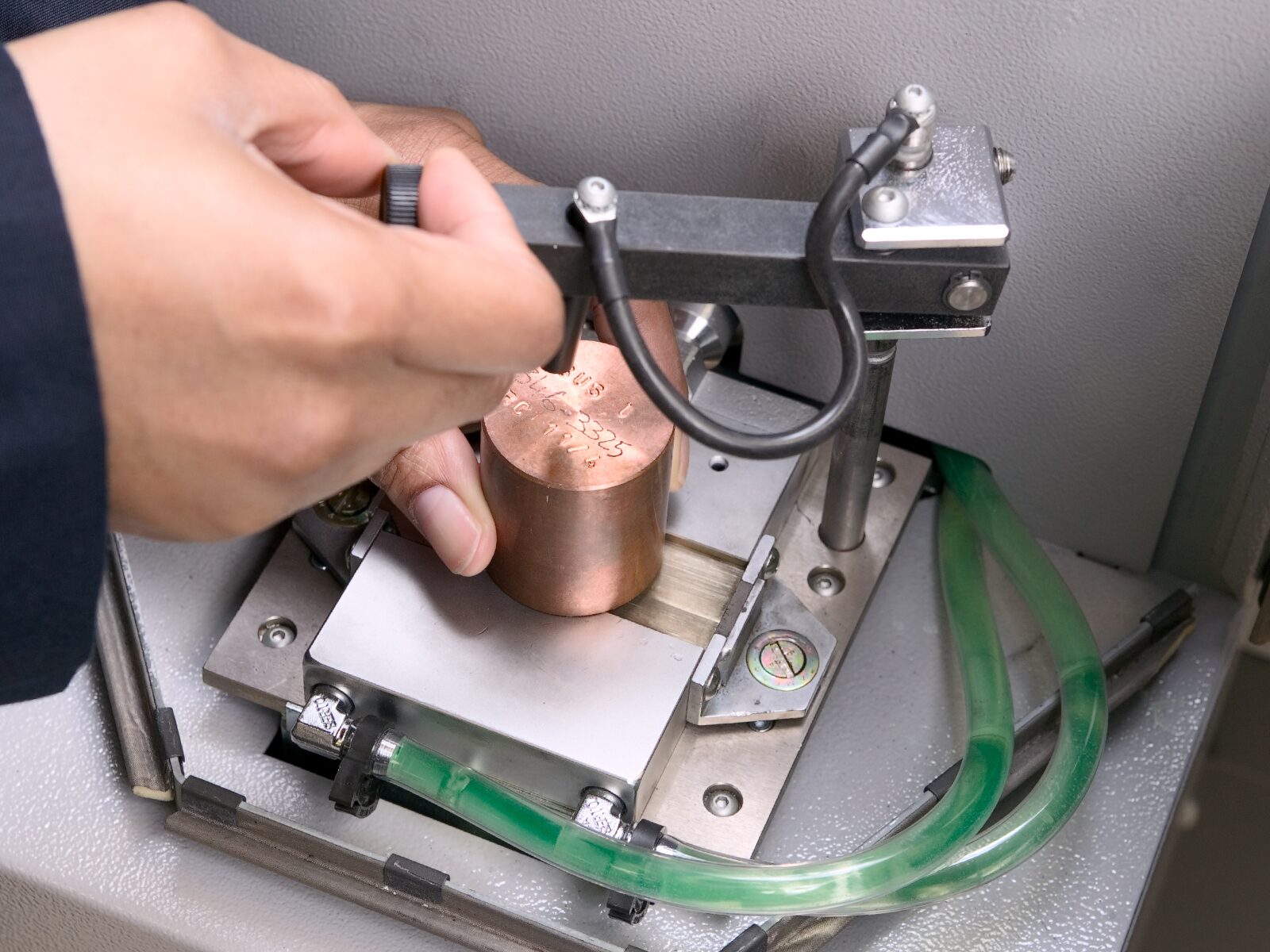

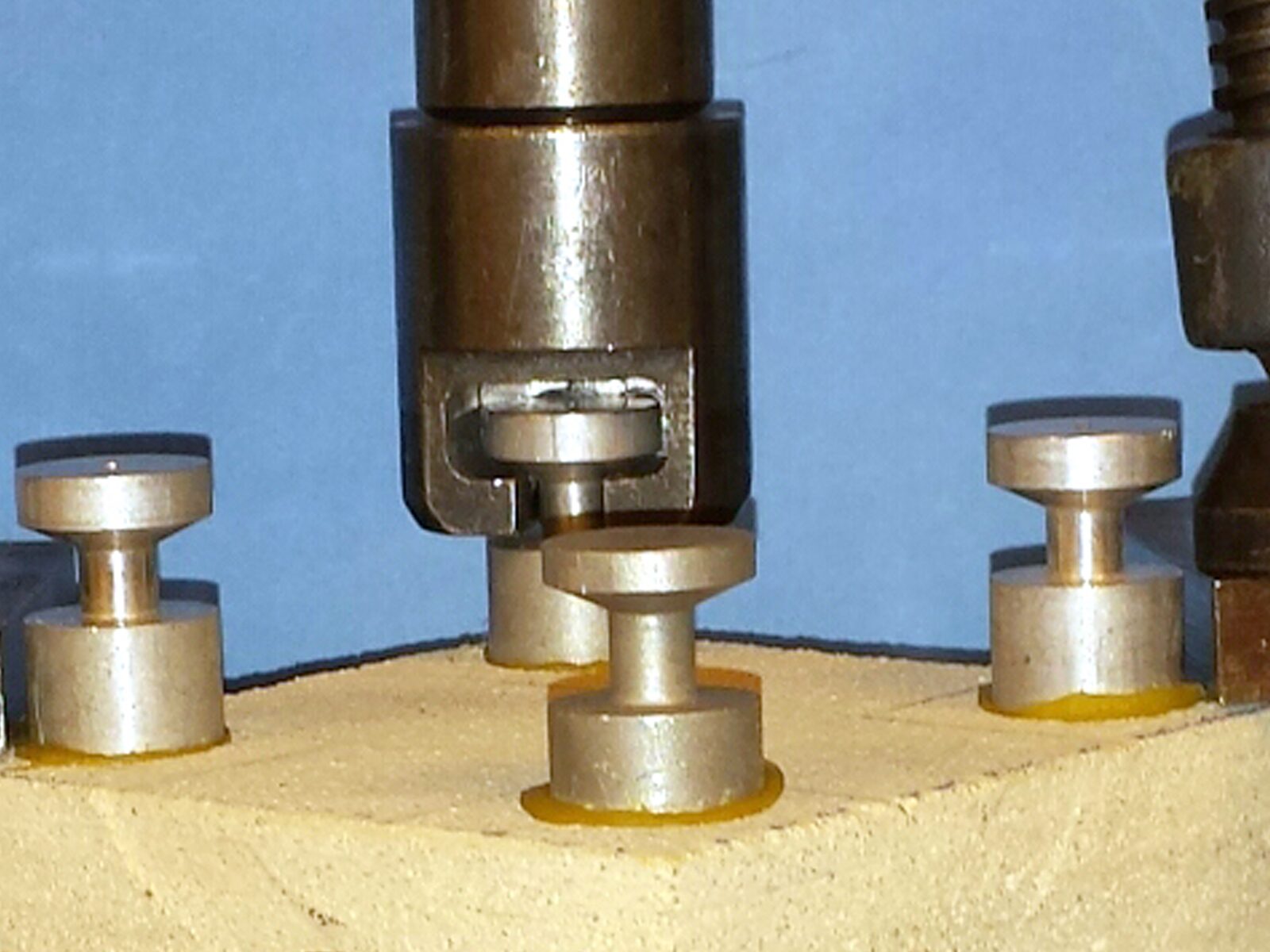

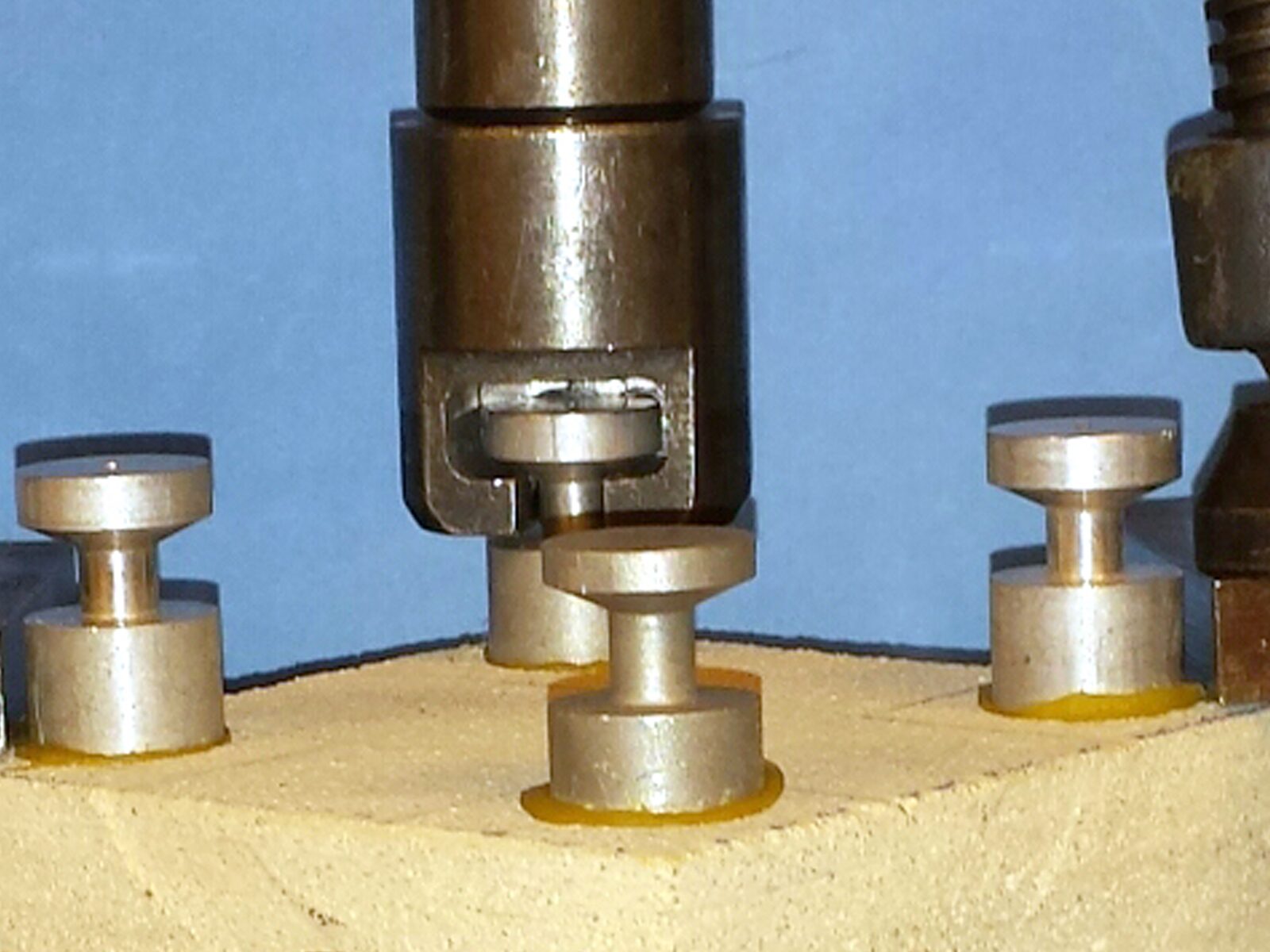

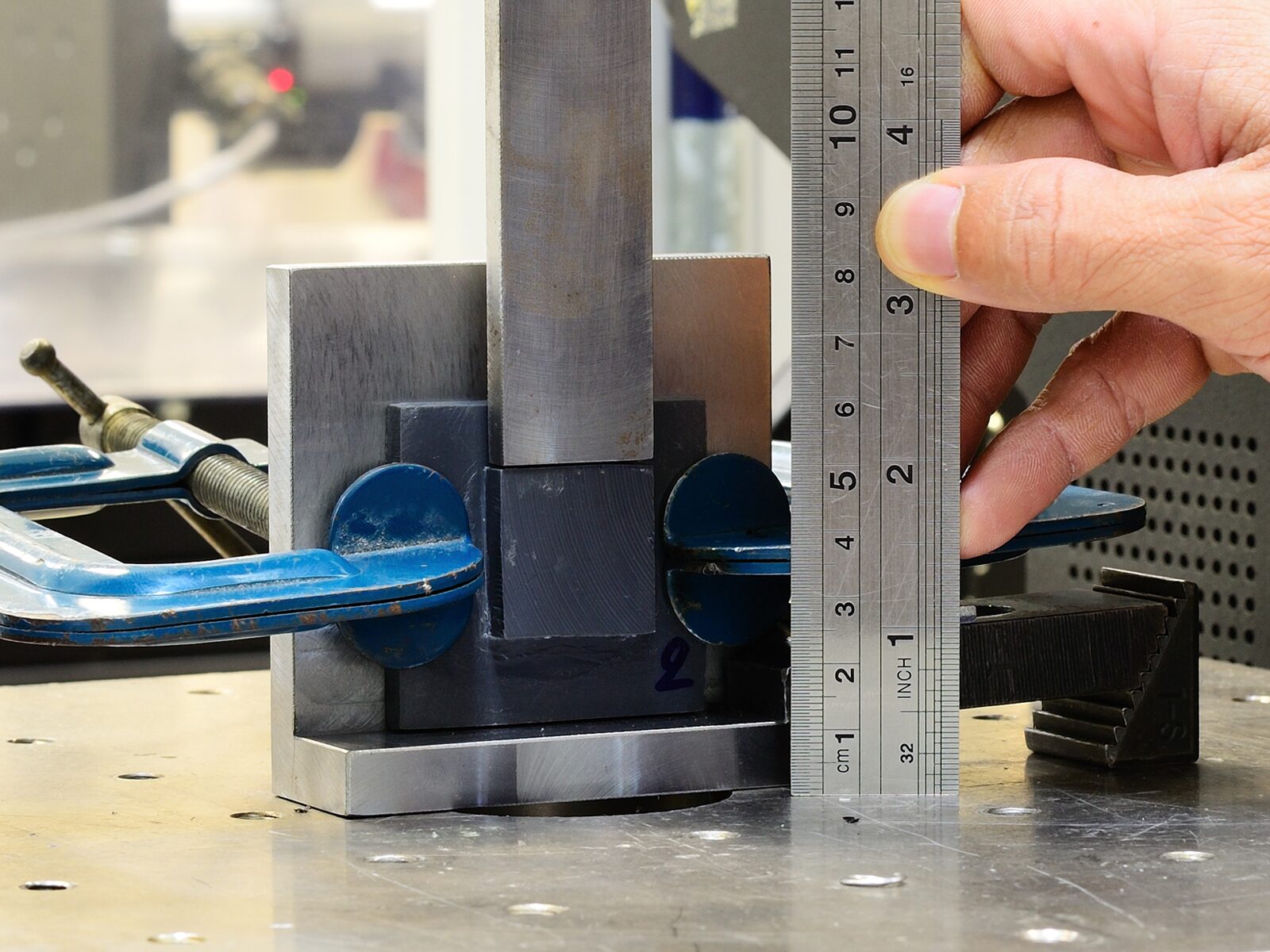

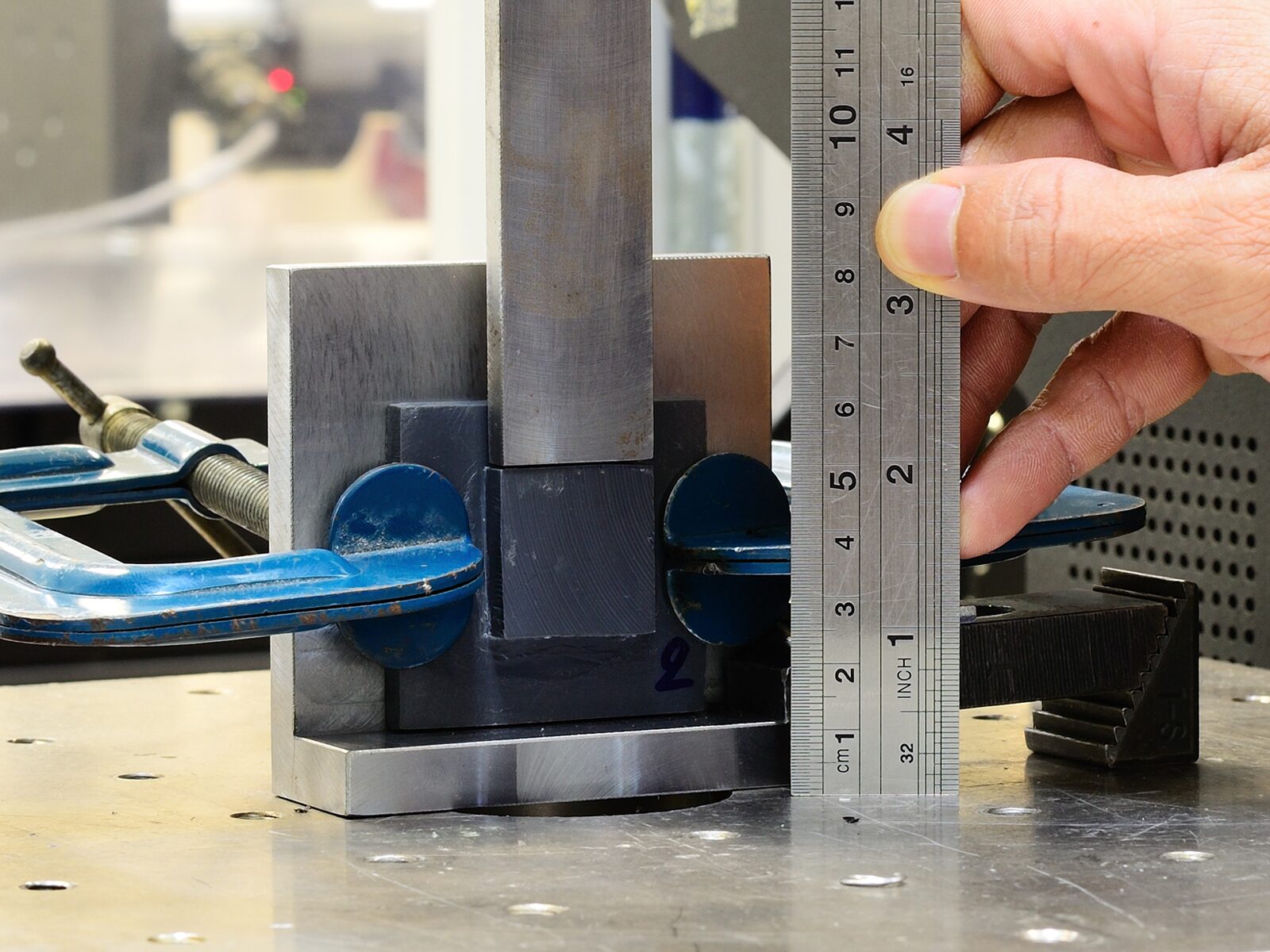

ASTM Brinell Hardness Testing

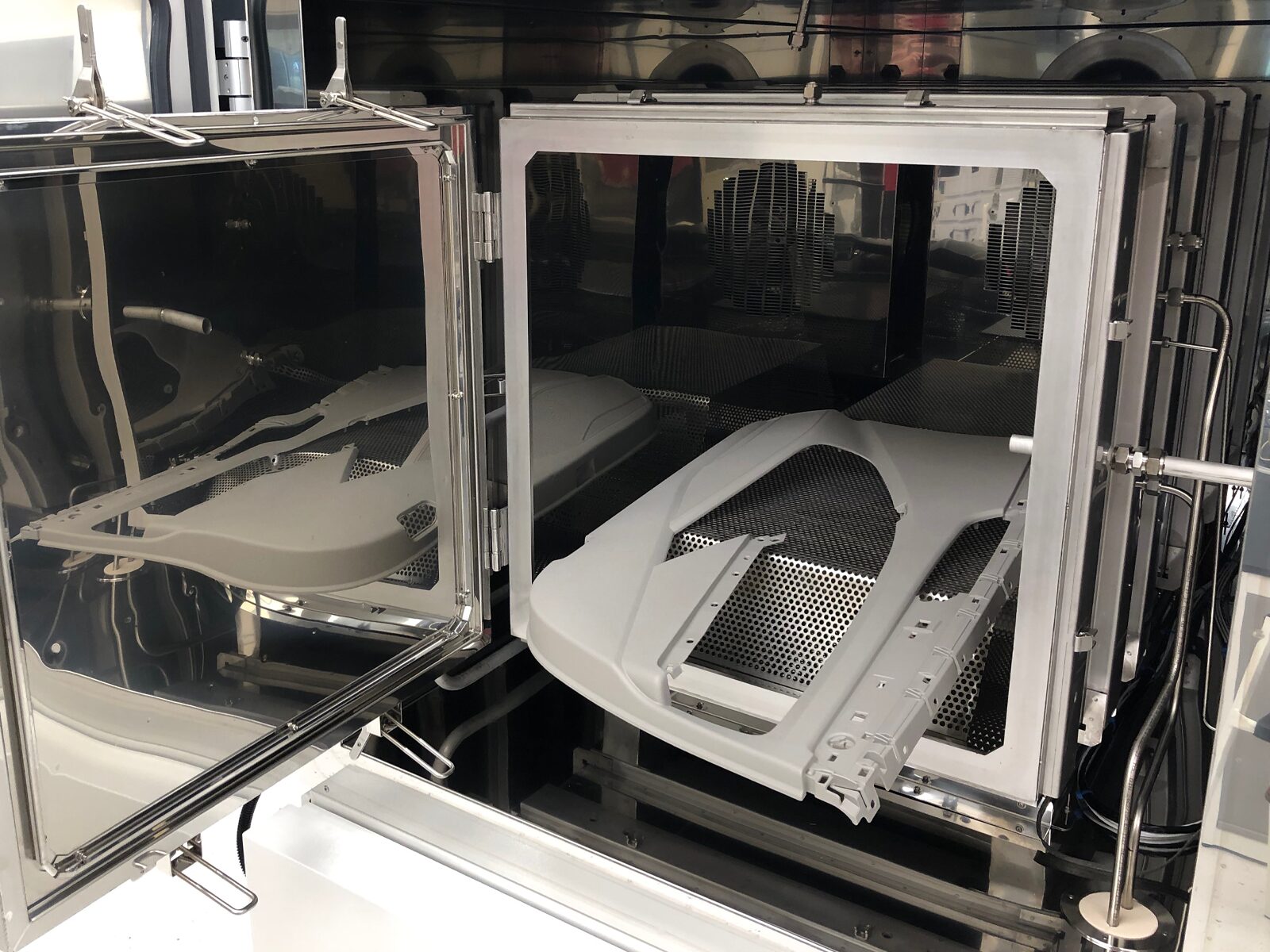

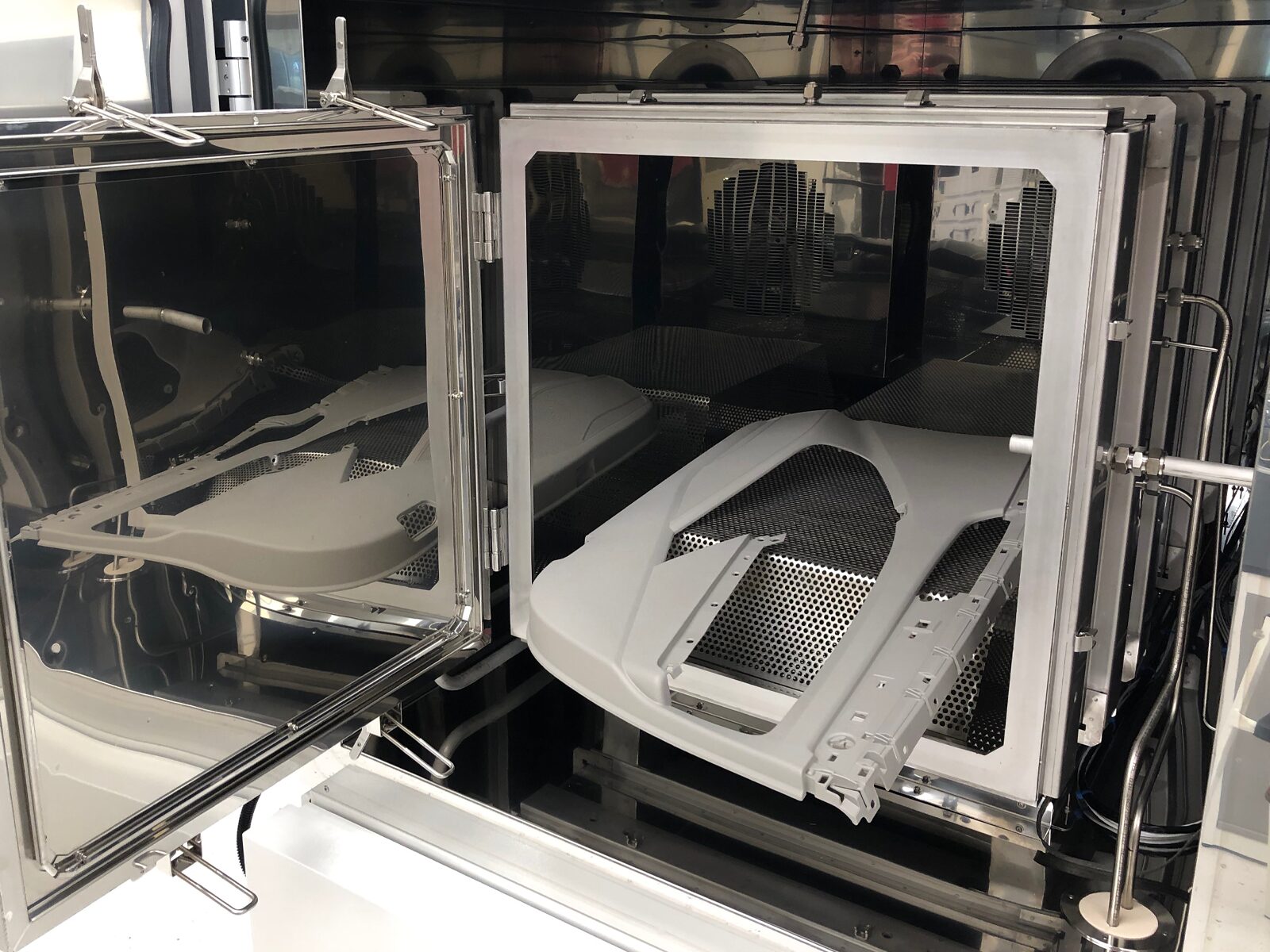

ASTM D4332 Testing: Environmental Conditioning

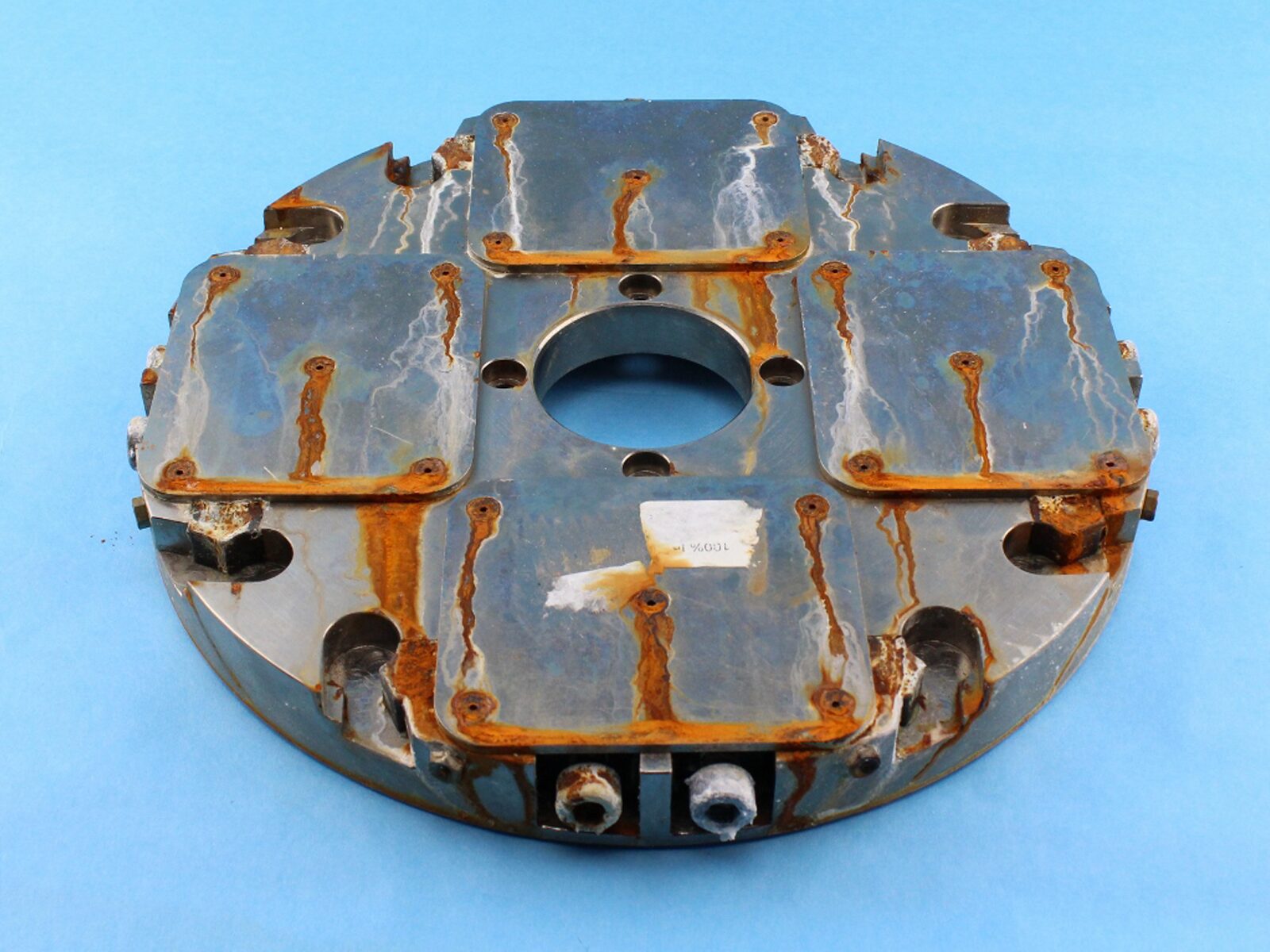

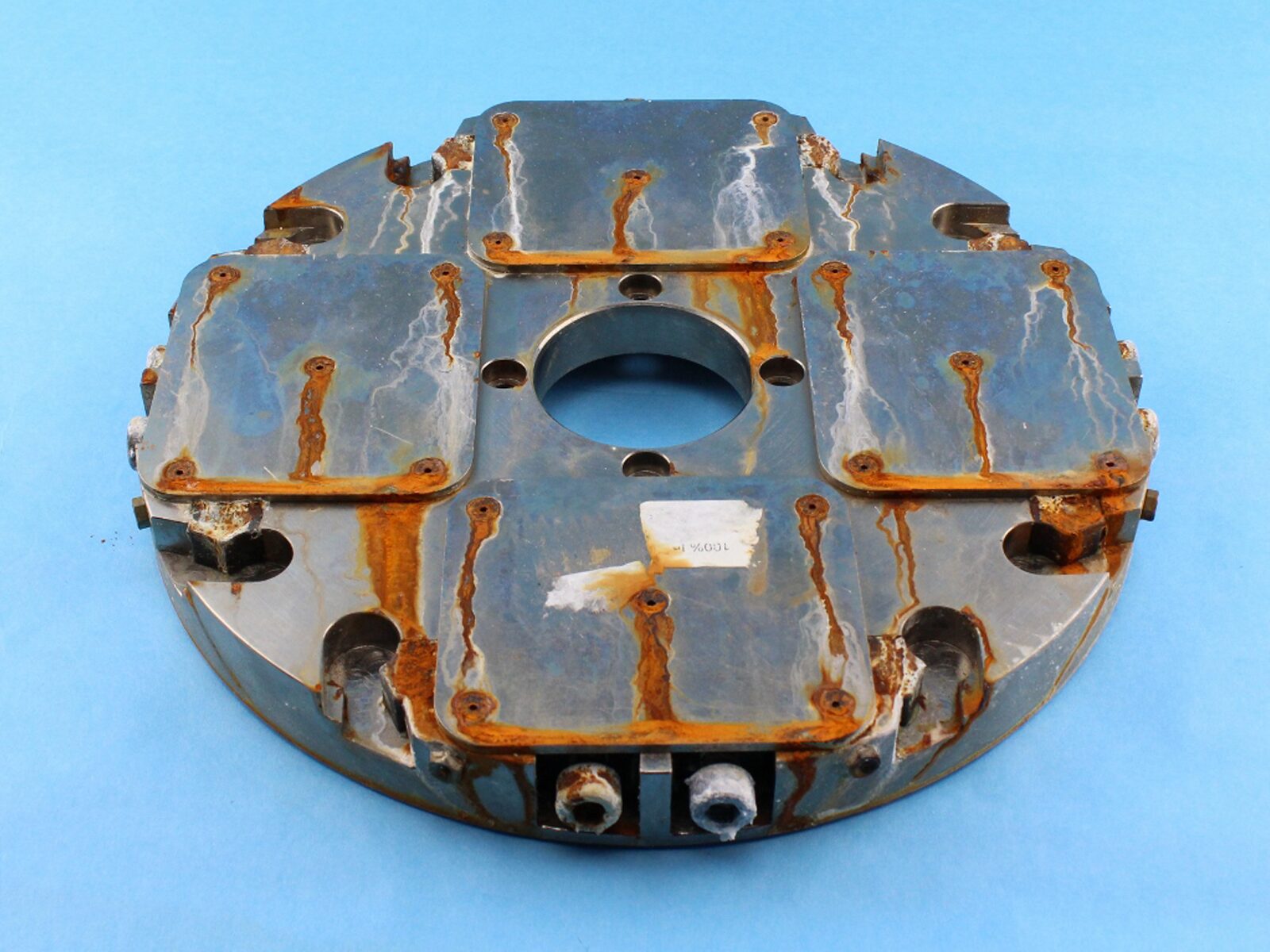

ASTM Corrosion Testing

ASTM B117 Salt Spray

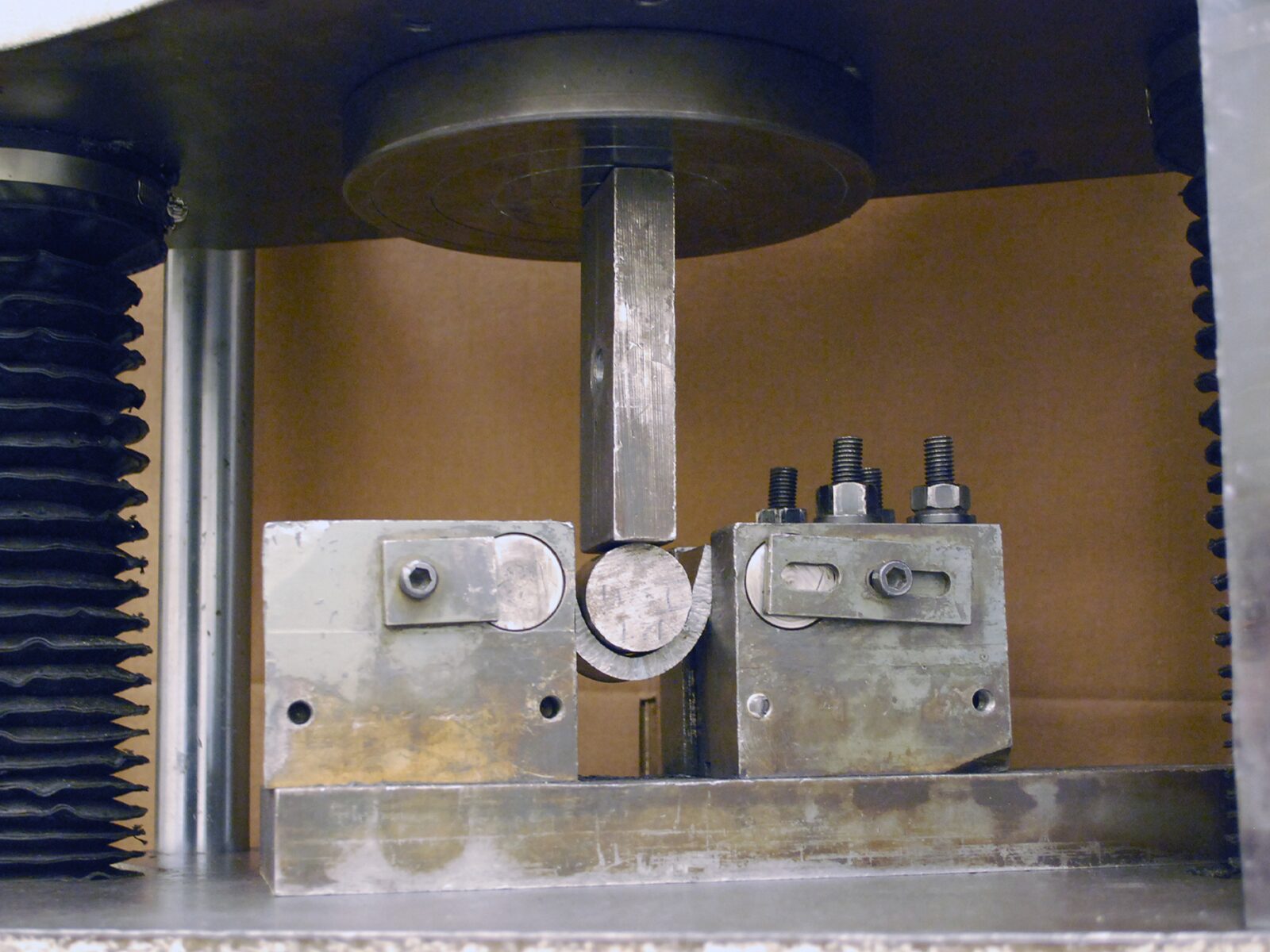

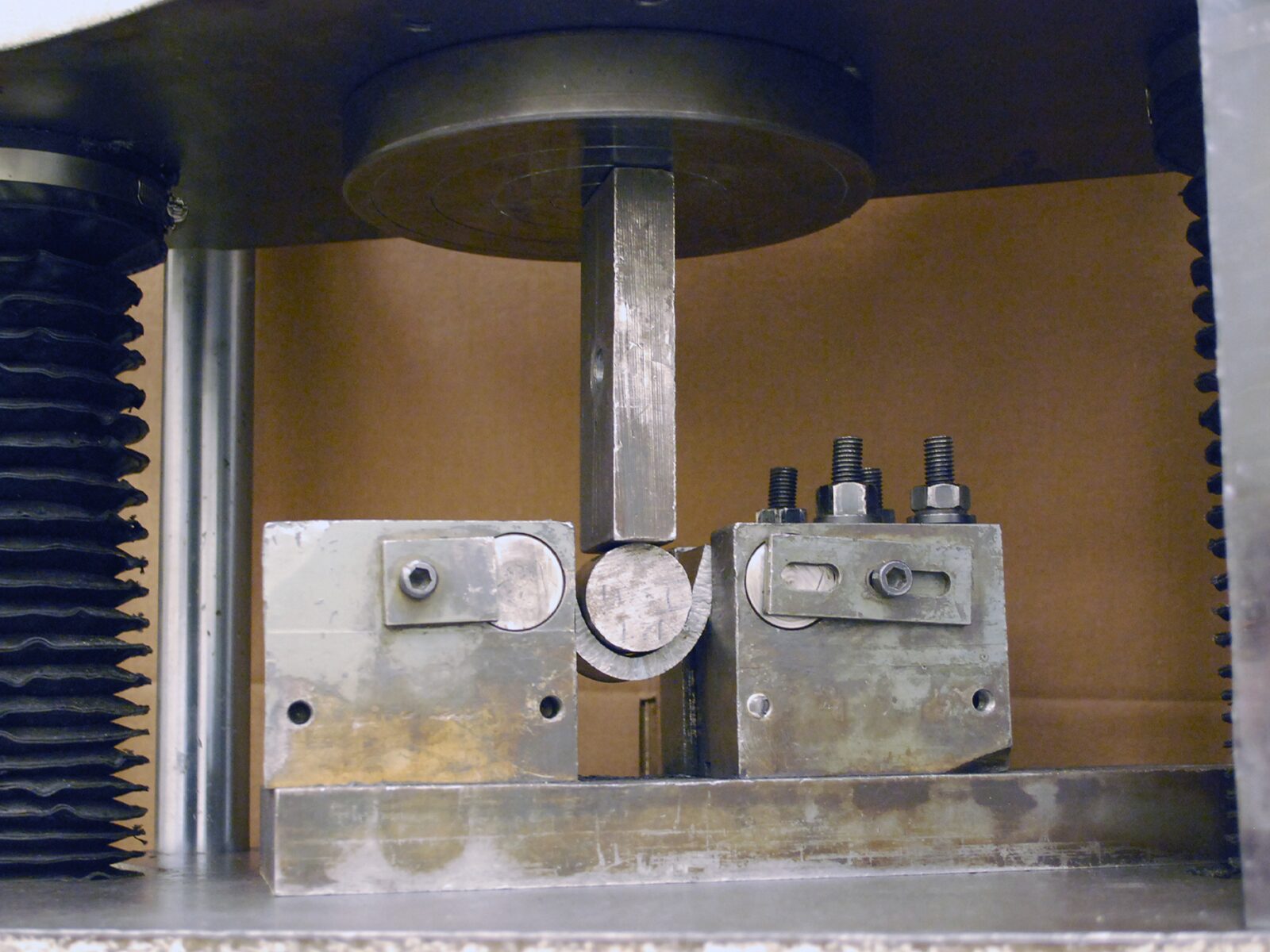

ASTM A370 Testing

ASTM B117 Testing

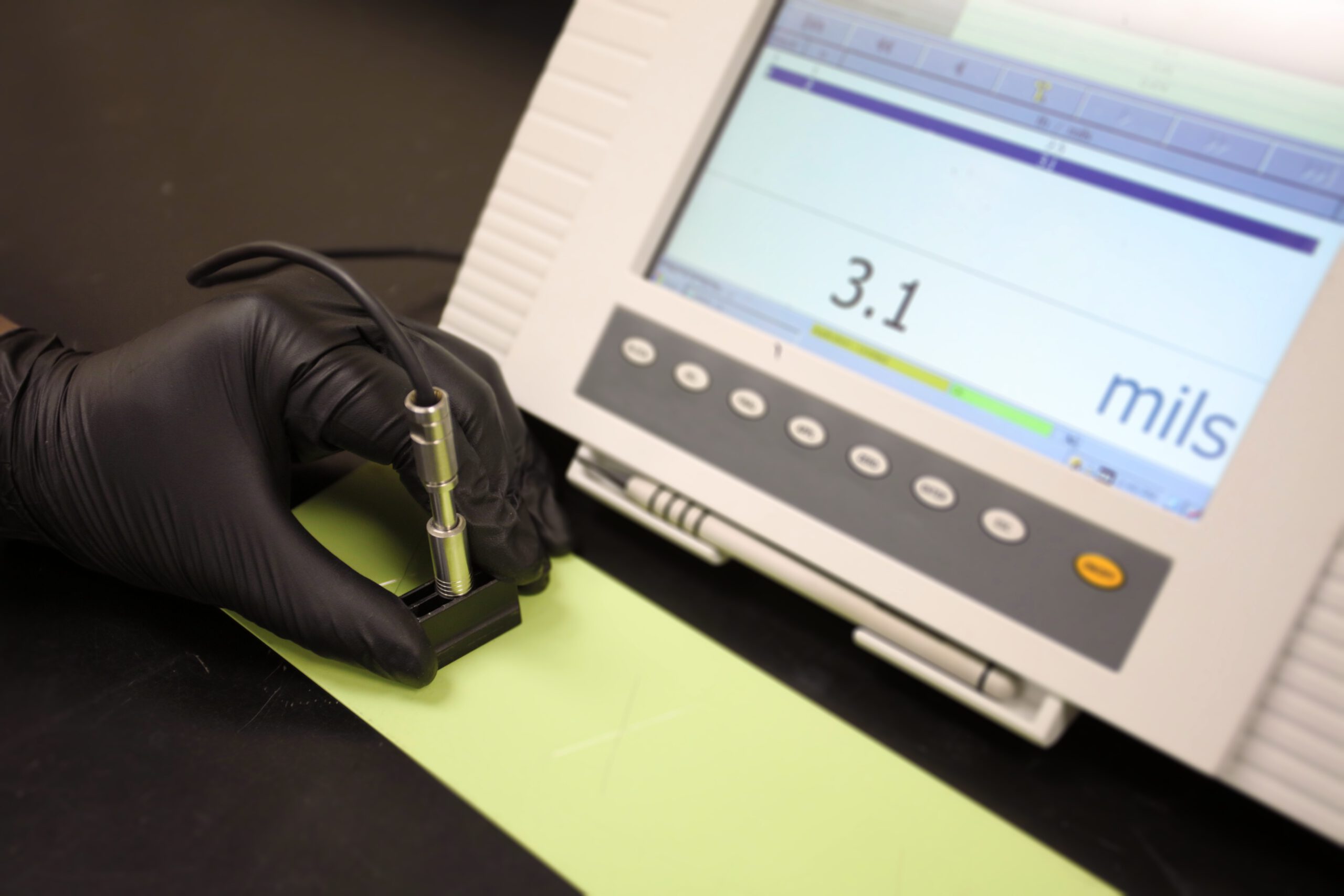

ASTM B137 Testing

ASTM C273 Testing

ASTM C393 Testing

ASTM C633 Testing

ASTM D1002 Testing

ASTM D1349 Testing

ASTM D2244 Testing

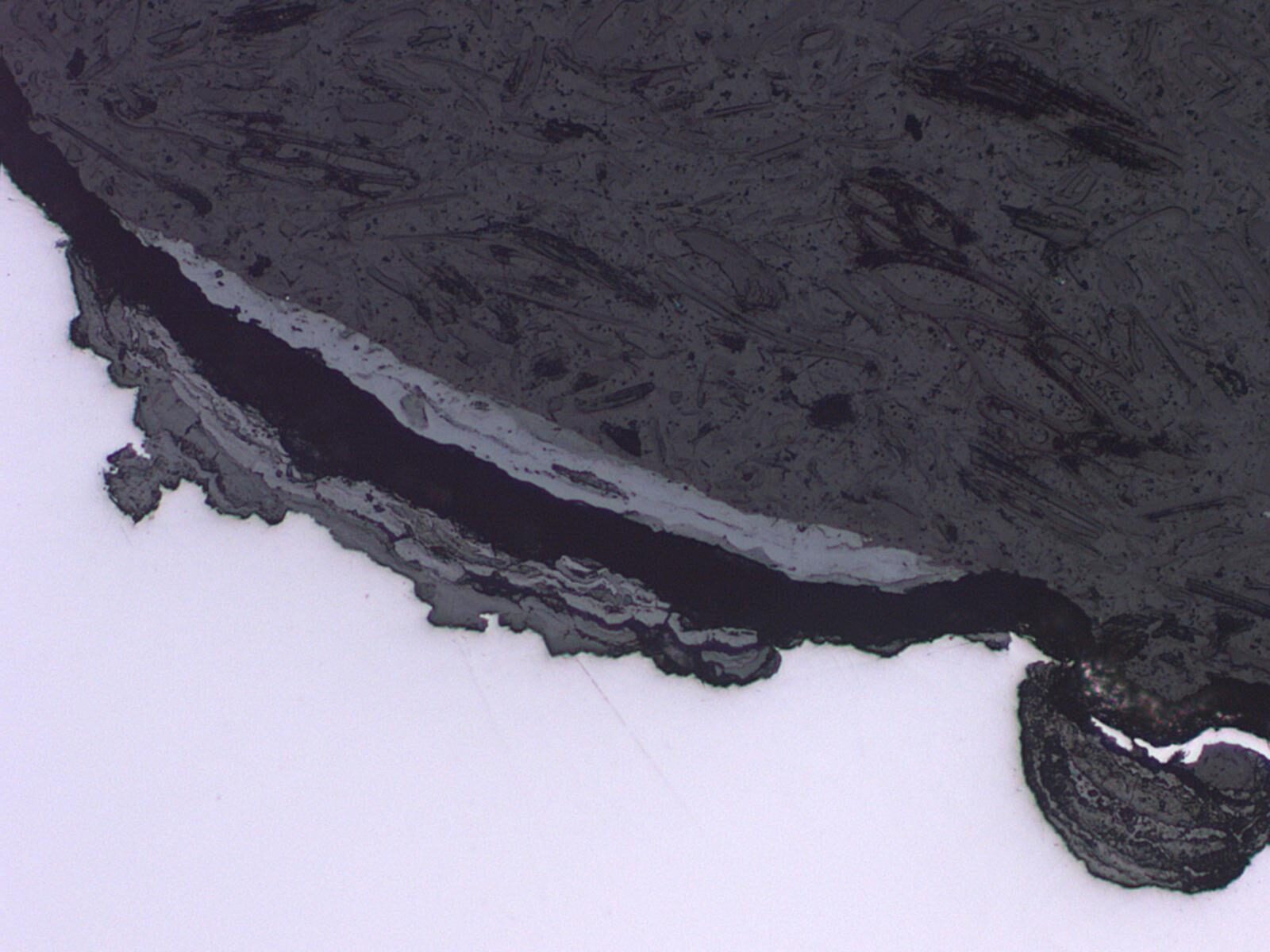

ASTM D2247 Testing

ASTM D2344 Testing

ASTM D2794 Testing

ASTM D3163 Testing

ASTM D3170 Testing

ASTM D3359 Testing

ASTM D3654 Testing

ASTM D4060 Testing

ASTM D412 Testing

ASTM D4332 Testing

ASTM D4541 Testing

ASTM D471 Testing

ASTM D522 Testing

ASTM D5229 Testing

ASTM D523 Testing

ASTM D5276 Testing

ASTM D5868 Testing

ASTM D618 Testing

ASTM D638 Testing

ASTM D642 Testing

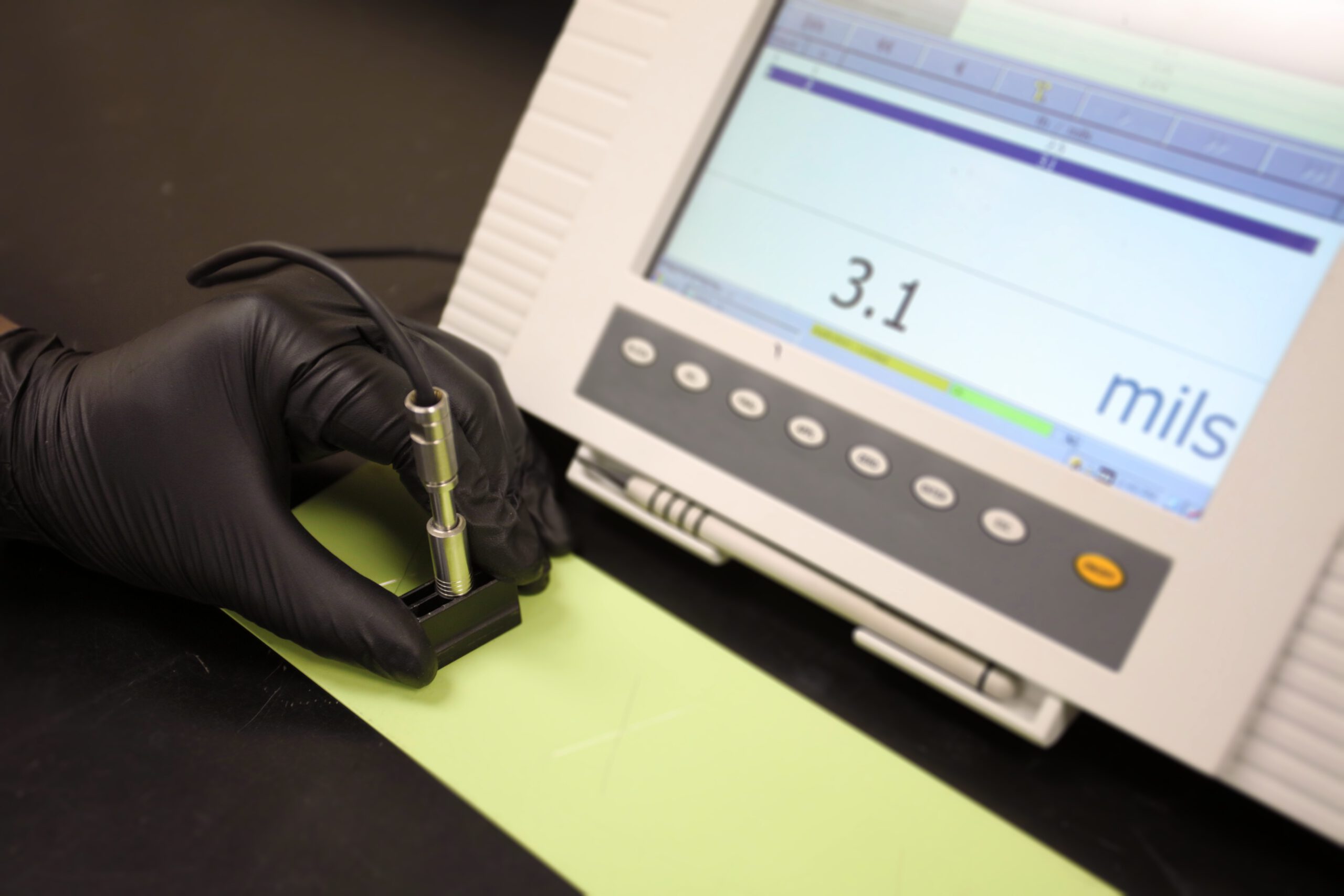

ASTM D7091 Testing

ASTM D732 Testing

ASTM D7617 Testing

ASTM D790 Testing

ASTM D8142 Testing – VOC

ASTM D999 Testing

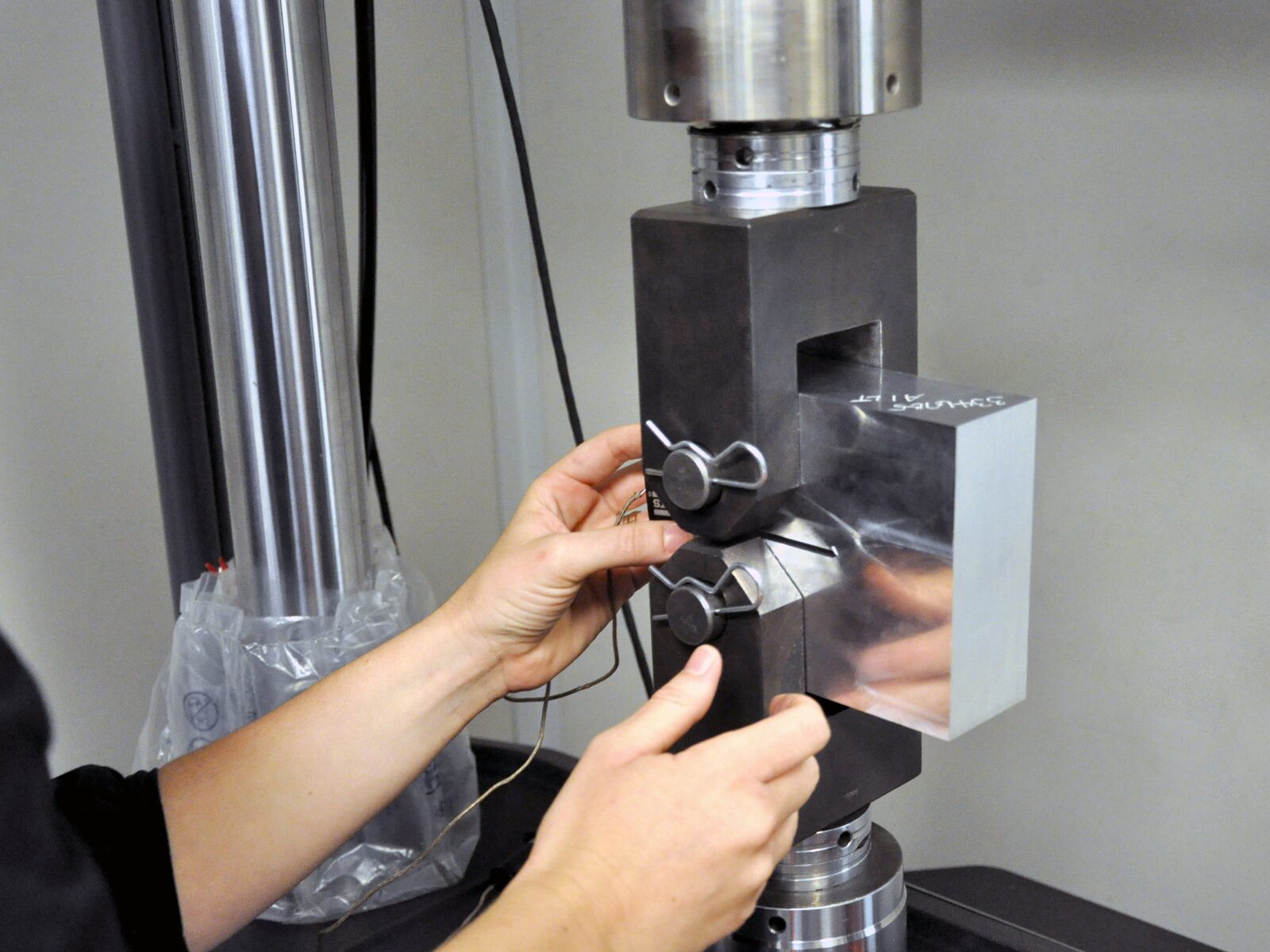

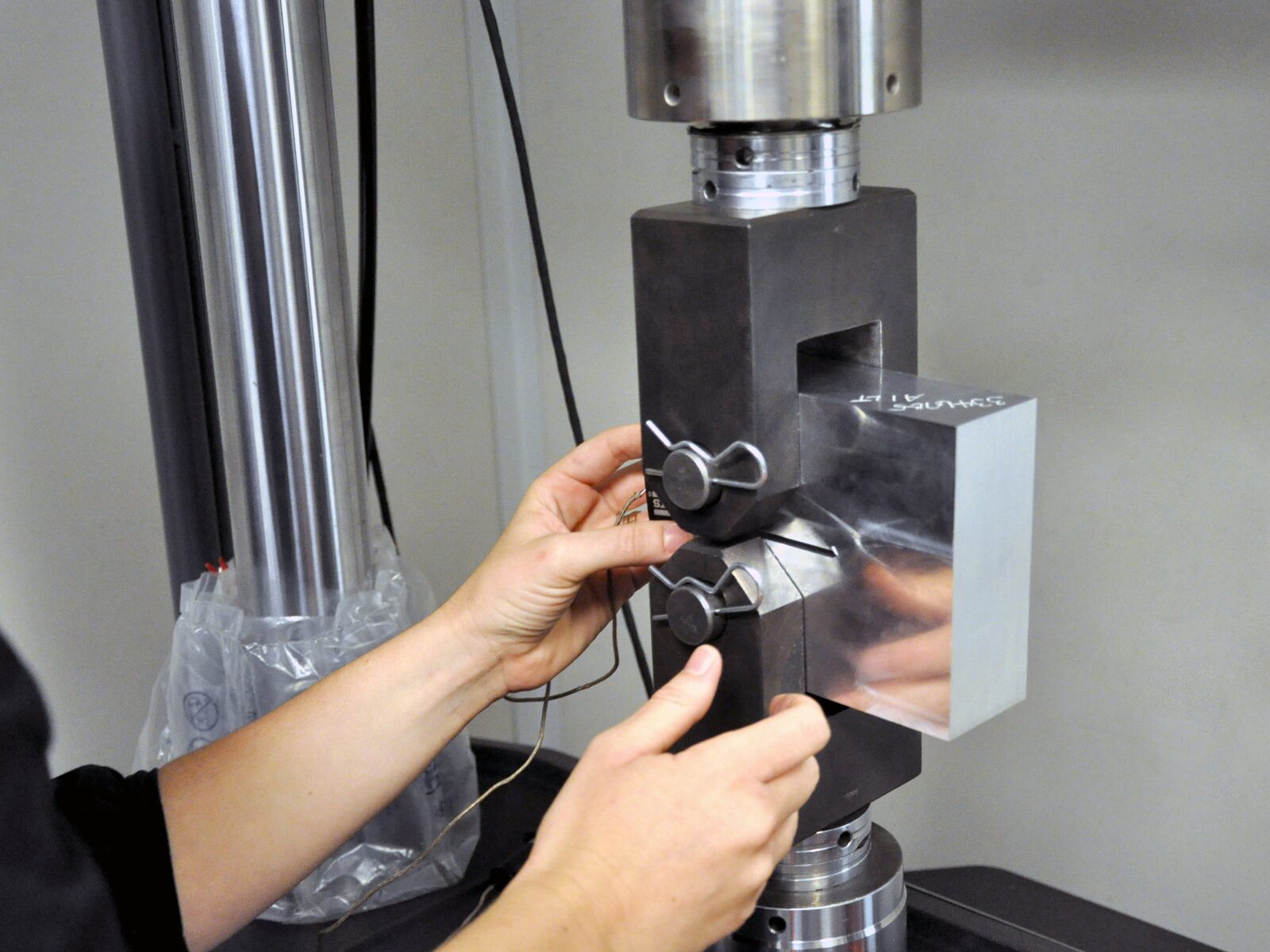

ASTM E111 Testing

ASTM E132 Testing

ASTM E132 Testing Lab

ASTM E1820 Testing

ASTM E190 Testing

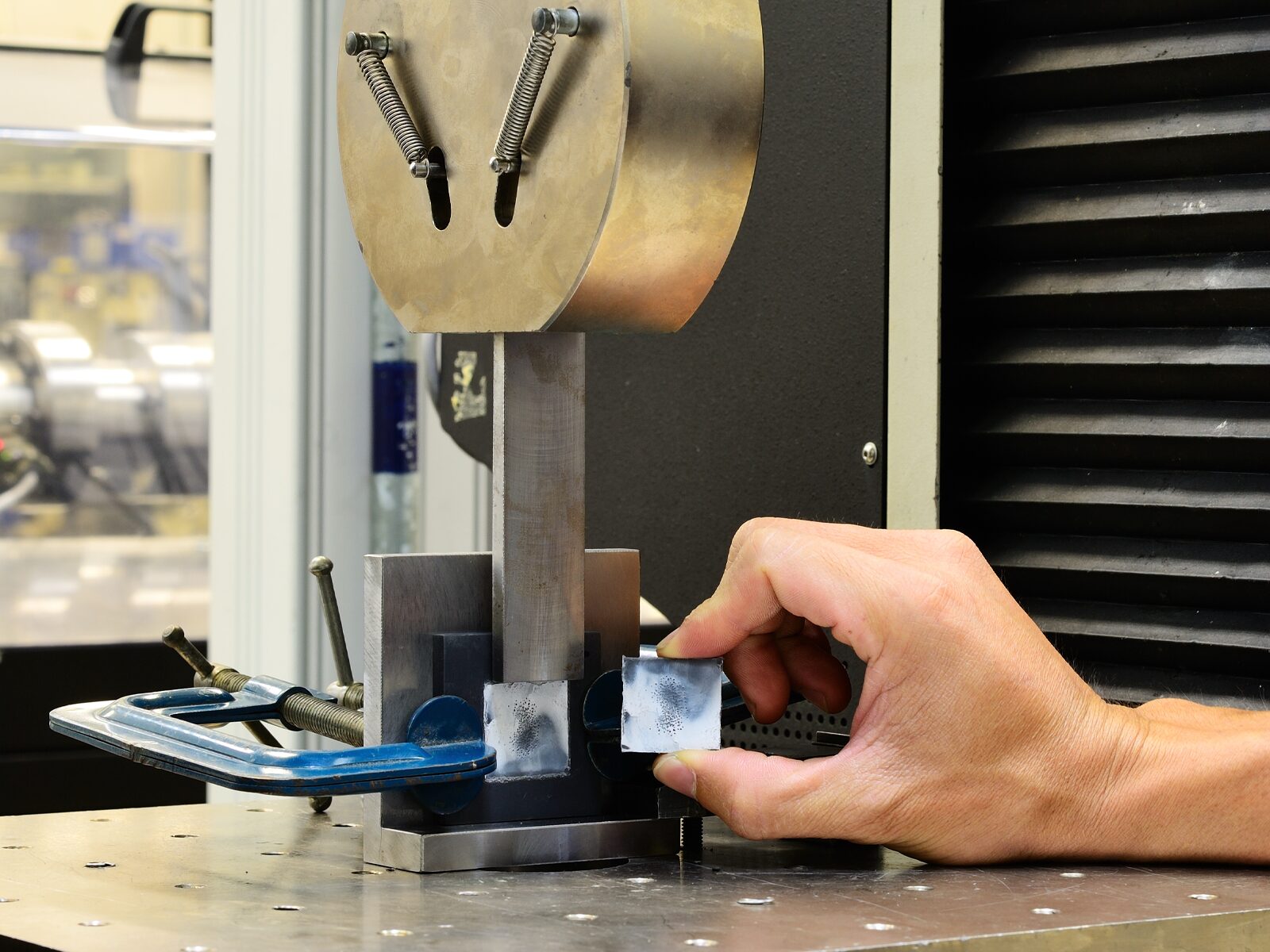

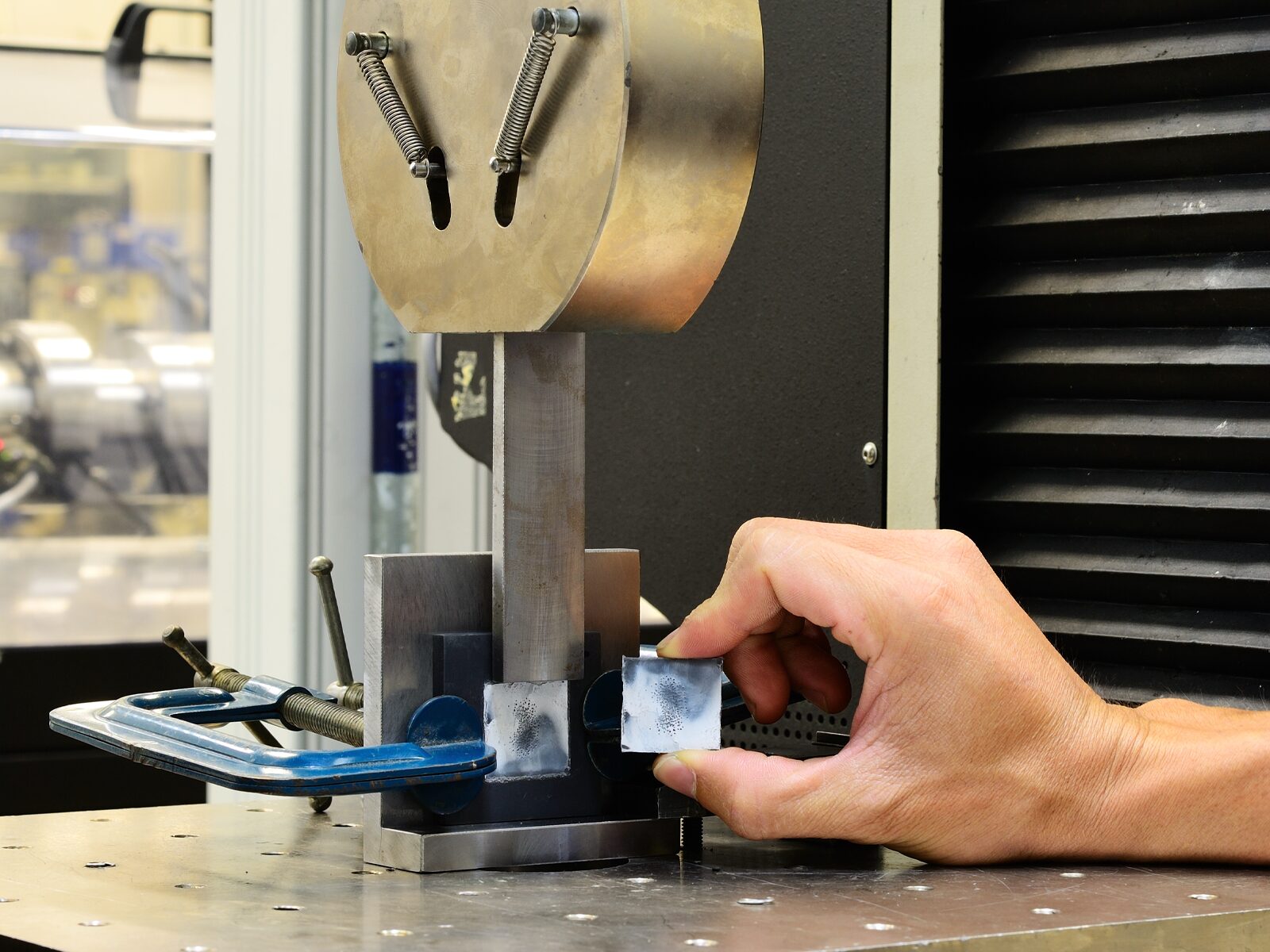

ASTM E23 Charpy Impact Test

ASTM E45 Testing

ASTM E606 Fatigue Testing

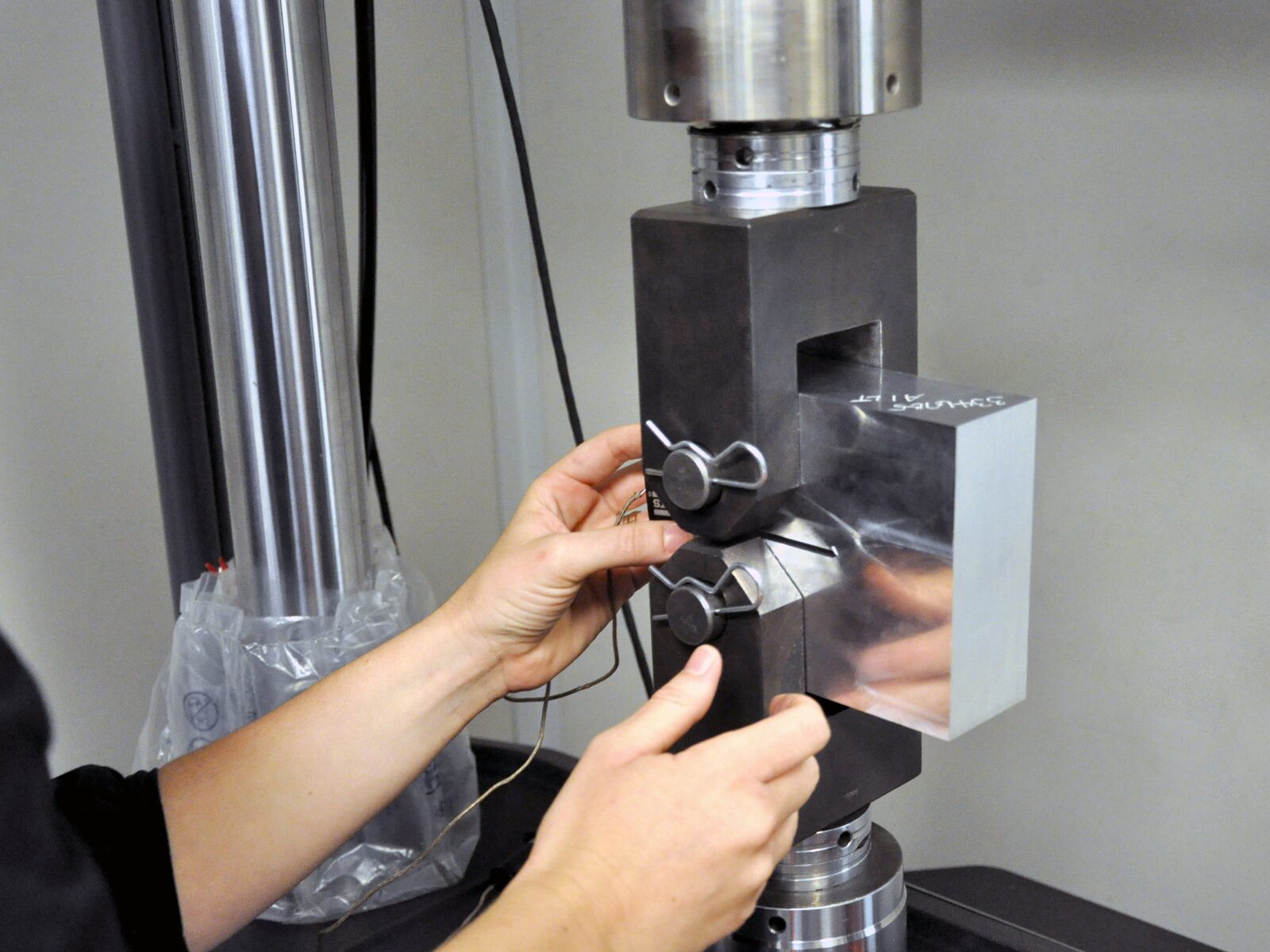

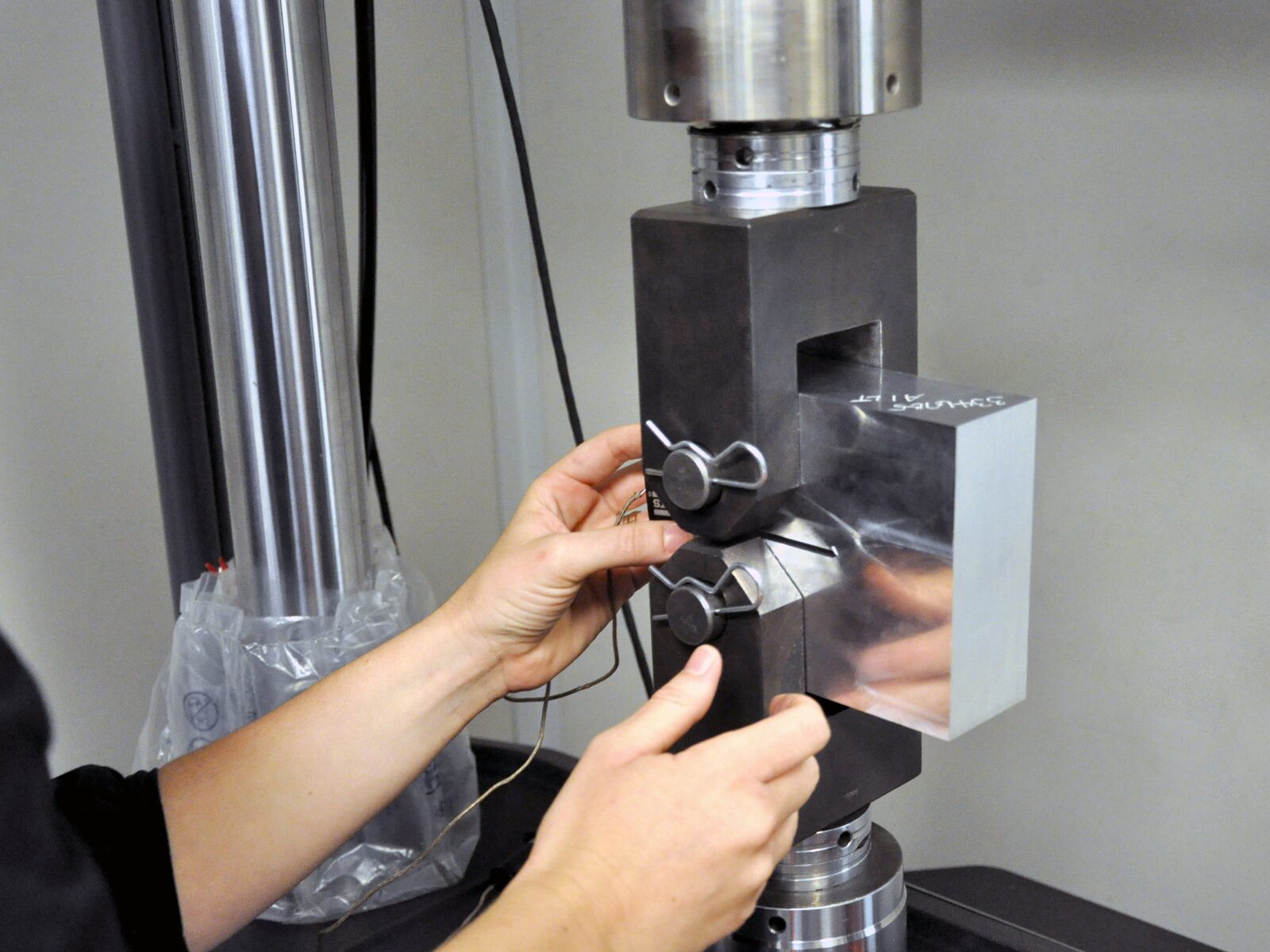

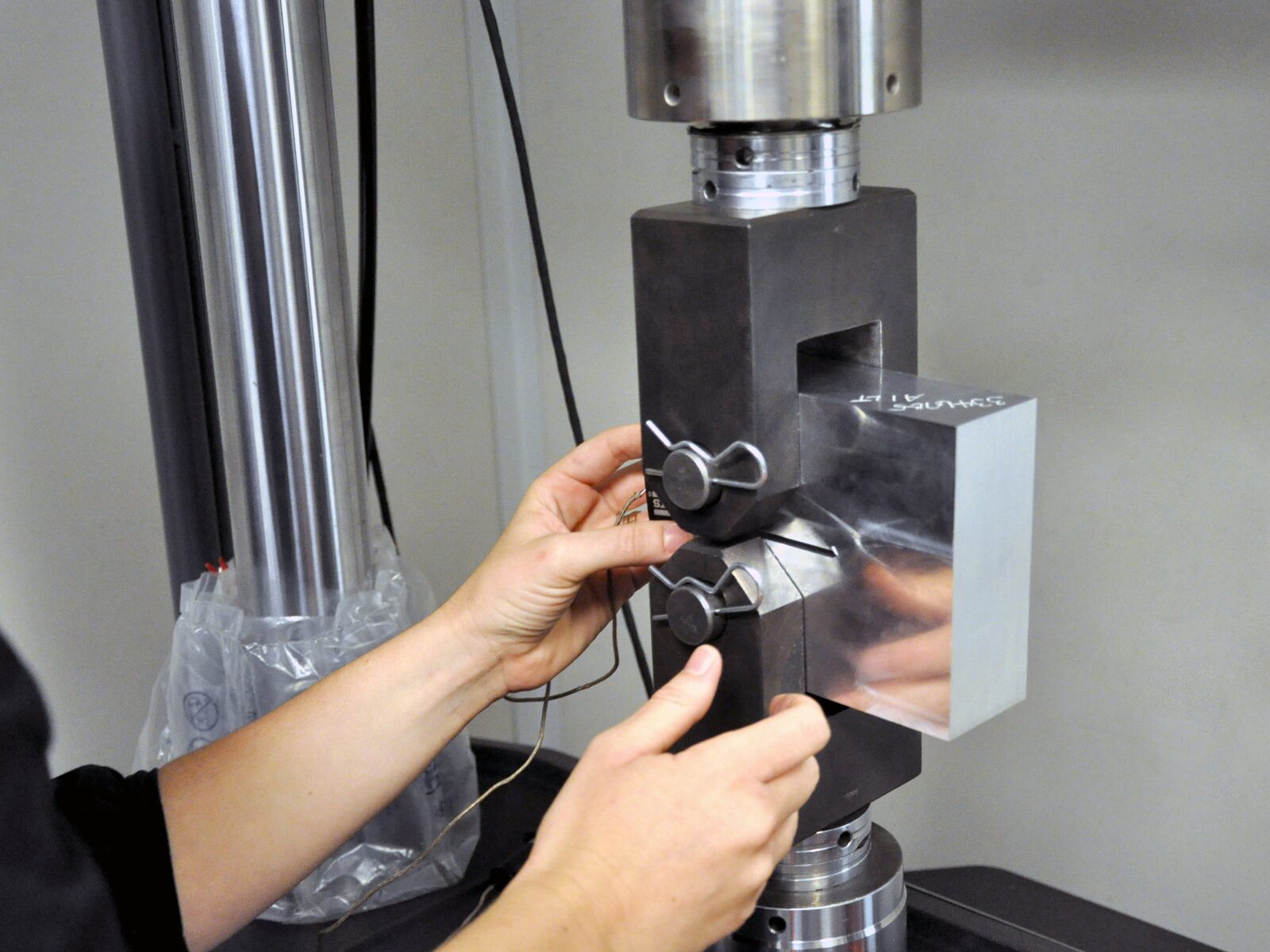

ASTM E8 Metal Tensile Testing

ASTM F1140 Testing

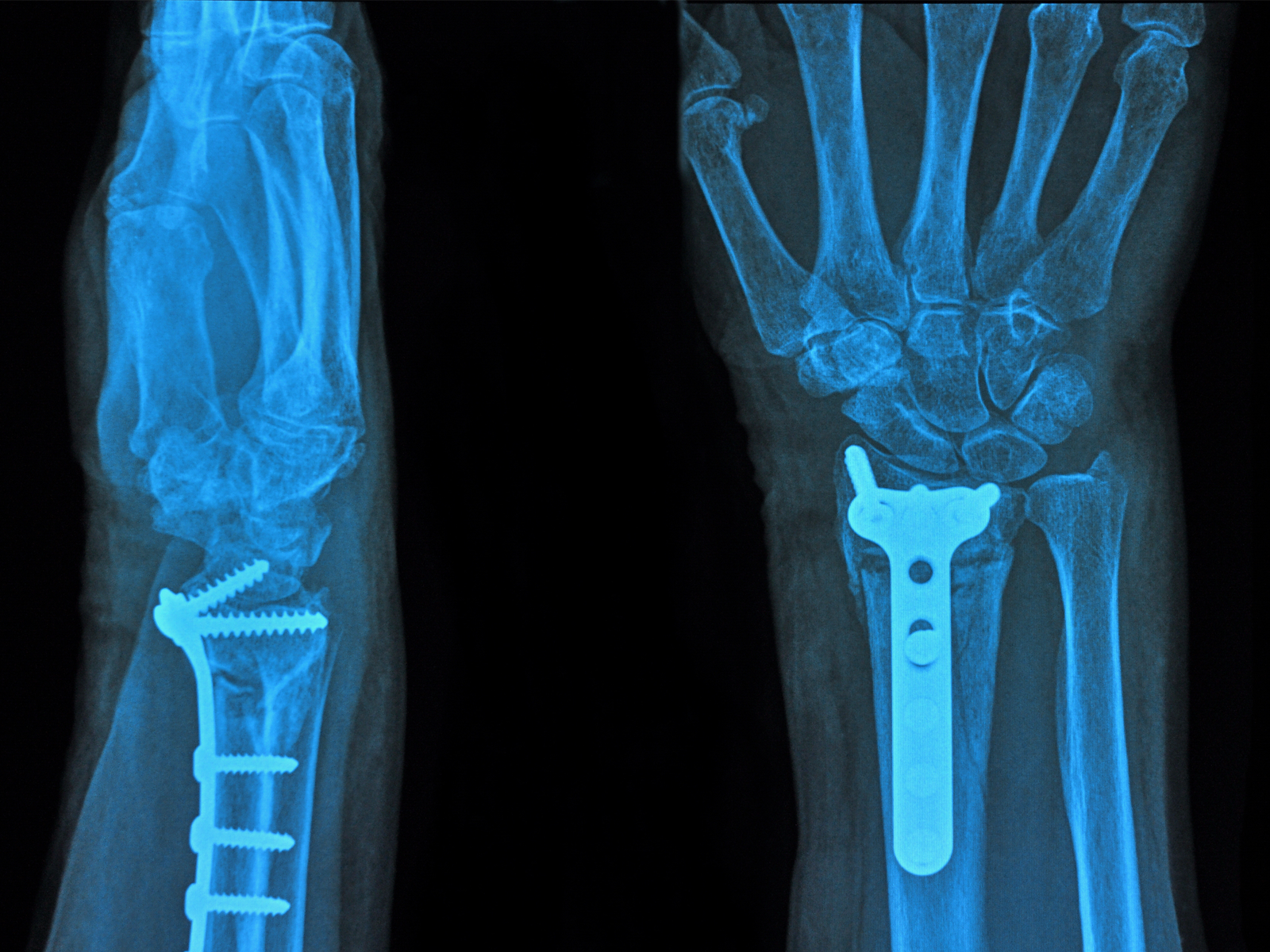

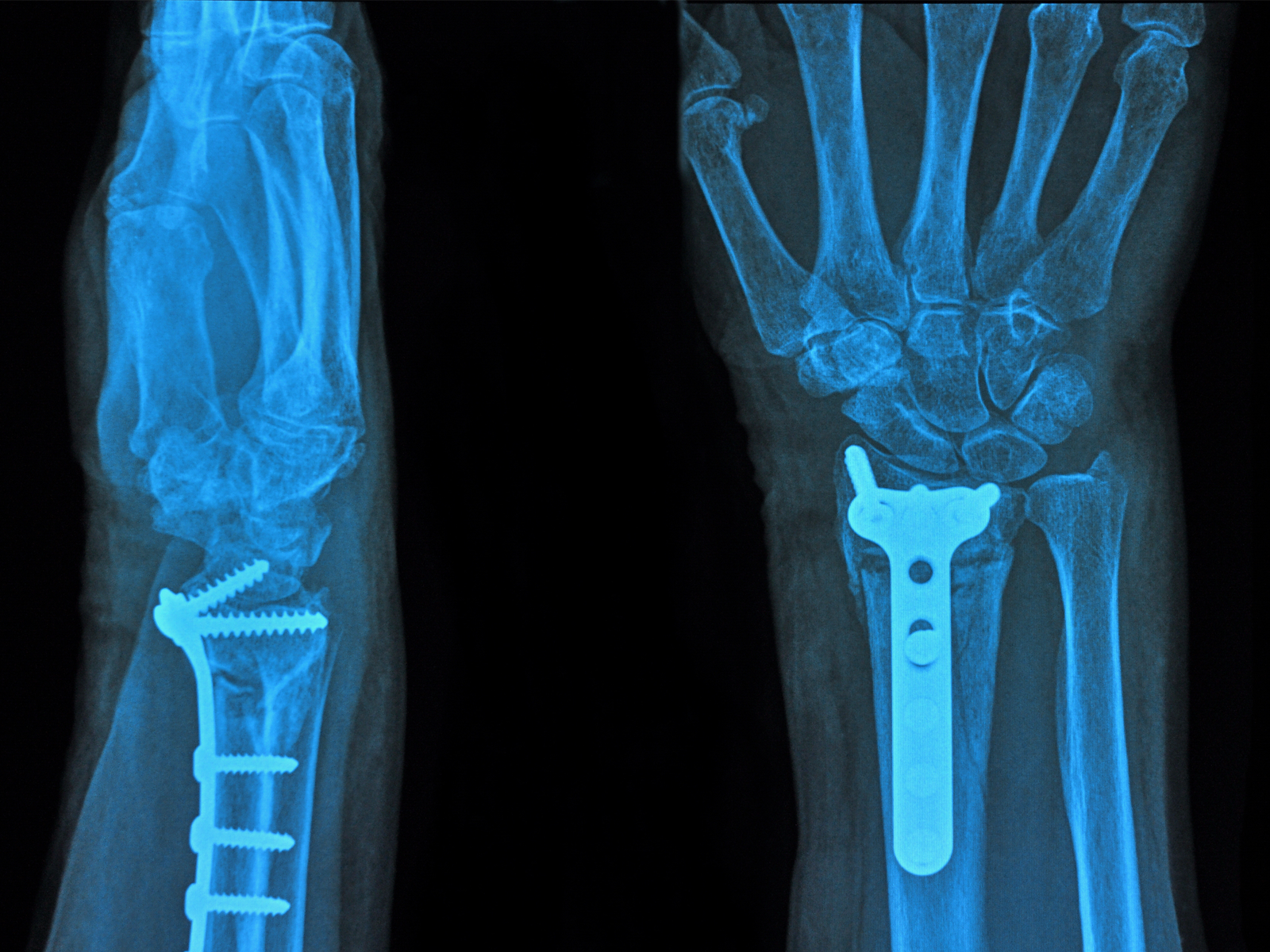

ASTM F1357 Articulating Total Wrist Implant Testing

ASTM F1378 Shoulder Prostheses Testing

ASTM F146 Testing

ASTM F152 Testing

ASTM F1714 Gravimetric Wear Assessment of Prosthetic Hip Design in Simulator Device Testing

ASTM F1781 Elastomeric Flexible Hinge Finger Total Joint Implants Testing

ASTM F1929 Testing

ASTM F1980 Testing

ASTM F2096 Testing

ASTM F24 Inspections

ASTM F2824 Testing

ASTM F382 Metallic Bone Plate Testing

ASTM F519 Embrittlement Testing Services

ASTM F963-16

ASTM G154 Testing

ASTM G155 Testing

ASTM G85 Testing

ASTM Paint Adhesion Testing

ASTM Peel Adhesion Testing

ASTM Salt Fog Testing

ATS is a Nationwide Brand

Situated in key regions, our state-of-the-art facilities are where your story of assurance and progress unfolds. From aerospace to healthcare, our strategically placed labs are equipped to tackle your most pressing challenges with precision and dedication.

What We Cover

Industries we proudly serve

ATS is proud to offer specialized testing, engineering, and calibration services across a diverse array of industries. From aerospace and automotive to healthcare and renewable energy, our tailored solutions meet the unique needs and challenges of each sector.

Certifications & Standards

Qualifications you can trust

For more information about all of our current certifications, visit our Certifications & Standards page.

Connect With Us

Find an expert

Connect with our knowledgeable experts for guidance, insight, and analysis.

Stay ahead of the curve with ATS insights

Unlock exclusive industry insights, expert tips, and the latest updates from ATS by subscribing to our newsletter. Join thousands of professionals who trust ATS to keep them informed and inspired.