Applied Technical Services measures various materials’ fatigue crack growth rates using ASTM E647.

Understanding Fatigue Crack Growth and Fatigue Crack Growth Rate

Fatigue crack growth tests subject materials with pre-existing cracks to cyclic loading to evaluate the material’s reliability under stress, whereas crack growth rate tests assess the rate at which pre-existing cracks grow over time. Several factors cause crack propagation, including:

- Corrosion

- Fatigue

- Insufficient Maintenance

- Manufacturing Inconsistencies

- Repetitive Expansion / Shrinkage Cycles

- Temperature Changes

Crack growth can lead to further complications that compromise a material’s ability to function effectively and safely, so manufacturers rely on fatigue tests to evaluate a material’s resistance to crack growth. Failure to evaluate crack growth may lead to expensive repairs, safety violations, and abrupt fatigue failure.

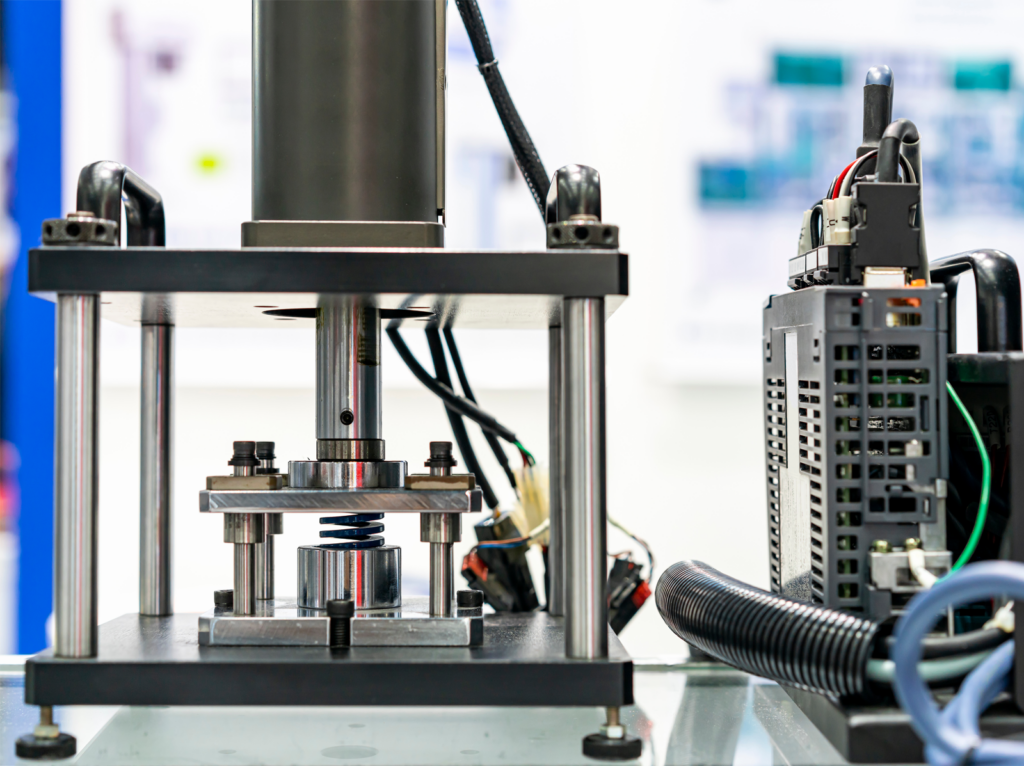

ASTM E647

The objective of ASTM E647 is to determine how fatigue crack propagation impacts the life of material subjected to cyclic loads. During the test, technicians expose pre-cracked specimens to cyclic loading that results in crack growth. The crack growth length is measured as a function of elapsed fatigue cycles to evaluate the crack growth rate. Technician express results as the crack-tip-stress-intensity factor range (DK), which is established by linear elasticity theory. The results offer insight into the mechanical limits of materials, allowing manufacturers to determine the ideal application for material and maintain quality control.

Applied Technical Services’ Fatigue Testing Services

Applied Technical Services conducts fatigue testing on various ceramics, polymers, and metals. Our ISO/IEC 17025:2017-accredited mechanical testing lab conducts fatigue testing and analysis services in compliance with common ASTM standards such as E399, E606, and E647. Our experts have decades of experience in disciplines beneficial to fatigue testing and remain dedicated to providing professionalism as promptly as possible.

Our Fatigue Testing Equipment Capabilities

- Temperature Range: Ambient to 1000°C

- Load Capacity: 2lbs to 55 Kip

About Applied Technical Services

Applied Technical Services offers quality consulting engineering, inspection, and testing services for companies worldwide. As an ISO 9001:2015-registered entity, we are committed to continuously improving our operation and service. We’ve greatly expanded our client base and list of services since our founding in 1967 and continue to earn the relevant accreditations and certifications to ensure quality service.

Please call +1 (888) 287-5227 or submit a web request to speak with an ATS representative for further details regarding our fatigue testing services.