- Home

- Services/IndustriesServicesindustries

- About Us

- LocationsStatesAccordion ContentAccordion ContentAccordion ContentAccordion Content

- Job Openings

- Quick Links

- ATS Family

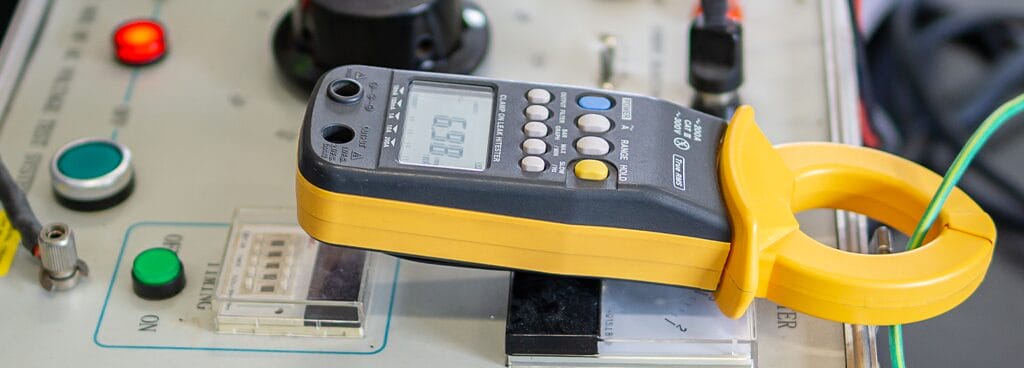

AC and DC HiPot Testing

Applied Technical Services (ATS) conducts pass/fail AC and DC HiPot tests to ensure equipment withstands the stresses of high-potential voltages without breakdown. Effective insulation must prevent current leakage and flow to remain safe and effective. HiPot testing explores the dielectric limits of materials, helping manufacturers and designers with material selection and quality assurance.

How Good is Your Insulation, Really?

Manufacturers request HiPot testing to verify their product is safe for the intended application or if it needs design changes. Our ISO/IEC 17025-accredited testing facility provides clients with documented proof of compliance with safety and performance regulations. An ATS expert can search for insulation flaws such as corrosion, short clearance distances, and creepage to assess the quality of the insulation and conductors in a component.

If your product requires other rigorous tests, we can save AC and DC HiPot testing for the end of a testing sequence to best simulate operating conditions that may introduce flaws and degradation to the insulation. We operate several labs with an array of ISO 17025 accredited testing scopes, including:

AC HiPot Testing

During an alternating current (AC) HiPot test, a powerful tester subjects a product to high voltages that exceed those anticipated in the product’s intended application. We deliver high electrical stress to determine whether a product can handle standard operation requirements and voltage spikes alike. While ATS usually tests at a frequency of 60 Hz, the American standard for electrical equipment, we can instead customize the procedure to apply other frequencies as appropriate.

A product that passes AC HiPot testing can serve in applications such as:

- Home appliances, from refrigeration to lamps

- Building lighting systems

- Utility lines across long distances

DC HiPot Testing

HiPot testing with direct current (DC) requires a product to endure sessions of increasing DC voltages in a process called ramping. Throughout the test, an ATS expert looks for signs of impending insulation breakdown that present safety hazards to users, equipment, and surroundings. Performing both AC and DC HiPot testing provides a more comprehensive analysis of insulation effectiveness than AC HiPot testing alone.

DC power delivers a stable energy flow that benefits battery charging, renewable energy, and electrical devices like smartphones and computers. Manufacturers may apply DC HiPot test results to compare a product’s dielectric withstand voltage with operating voltages and determine if the device meets quality requirements.

Testing with ATS

ATS serves a global client base as a testing, inspection, calibration, and engineering company headquartered in Marietta, Georgia. Clients can ship their devices to us for thorough lab testing and analysis or consult with our specialists on product validation scopes and procedures.

HiPot Testing involves the application of very high voltages; as such, this procedure requires an expert with training and experience to operate all equipment safely. The ATS electrical testing lab is ISO/IEC 17025 accredited and staffed with trained and experienced personnel who adhere to stringent safety standards and procedures when performing electrical tests in a controlled lab environment.

Our lab experts test to industrial standards from:

- IEC

- IEEE

- ASTM

- ANSI

- MIL-STD

Contact Us

Schedule HiPot testing with ATS for the confidence that your product performs to safety and quality expectations before it goes to market.

Call +1 (888) 287-5227 or complete the request form on this page to schedule AC and DC HiPot Testing for your product. To find out whether your device qualifies, speak with our representatives today.

Request Form

"*" indicates required fields

Electrical Testing

- AC Hipot Testing

- AC and DC HiPot Testing

- Battery Testing

- Battery Electrical Testing

- Battery Chemical Analysis

- Battery Pack Testing

- Bus Bar Hipot Testing

- Circuit Breaker Testing

- Conductivity ASTM B193

- Conductivity ASTM B193 testing

- Contact Resistance MIL DTL 5541 Testing

- Continuity Testing quote request form

- Consumer Electronics Testing

- DC Hipot Cable Testing

- DC Hipot Testing

- DC Hipot Testing of Medium Voltage Cables

- Dielectric Breakdown Testing

- Dielectric Constant Testing

- Dielectric Constant ASTM D150 Testing

- Dielectric Strength ASTM D149 Testing

- Dielectric Strength Quote Request Form

- Dielectric Strength Testing

- Dielectric Withstand Testing

- Dielectric Withstand Voltage Test

- DWV Electrical Test

- DWV Testing

- Electrical Failure Analysis Quote Request Form

- Electrical Testing EV Batteries

- Electrical Lab Services

- Electrical Load Testing Request Form

- Electrical Testing Lab

- Electrical Testing Laboratory

- Electrochemical Impedance Spectroscopy EV Testing

- Electronic Product Testing

- EV Battery Testing

- EV Battery Thermal Testing

- General Electric Testing Quote Request Form

- HiPot Cable Testing

- HiPot Testing

- Hipot Testing Motors

- HiPot Testing Services

- Lithium Ion Battery Testing

- IEC 60502-2 Hipot Test

- IEC 60950 Hipot Test

- IEC 60950 Testing

- Insulation Resistant Testing

- Insulation Resistant quote request form

- Photovoltaic Testing

- Polorization Index Testing

- Resistivity Testing Quote Request Form

- SAE J1455 Recommended Environmental Practice for Heavy Trucks

- SAE J2464 Testing

- SAE J2464 Electric and Hybrid Electric Vehicle Rechargeable Energy Storage (RESS) Safety and Abuse Testing

- Soil Resistivity Testing

- Thermal Testing EV Batteries

- VLF Cable Testing

- Voltage Drop Testing