The growing Applied Technical Services Family of Companies (FoC) performs comprehensive industrial scale calibration in our ISO/IEC 17025:2017-accredited calibration labs and in the field. Scales and balances require regularly scheduled calibration to ensure clients get the most out of their heavy-duty equipment and meet critical business objectives for quality control, logistics, regulatory compliance, and safety.

How the Environment Impacts Your Scale

ATS calibrates rugged industrial scales to counter the effects of heavy use. While all devices experience wear and tear as they age, industrial scales often operate in outdoor and industrial settings where they are more susceptible to harsh conditions. All scales include a load cell that responds to force, interpreted as weight. The load cell expands and contracts due to temperature fluctuations, such as exposure to direct sunlight and seasonal changes. Over time, these oscillating temperatures cause a subtle drift in the scale’s readings.

Scale accuracy can also degrade under the typical rigors of their operating environment:

- Air pressure

- Creep

- Dust

- Elevation

- Moisture intrusion

- Vibration

ATS Calibrates Precise Scales

We calibrate devices that measure small samples, such as analytical balances and precision scales. These tools have applications in industries that rely on close measurements, such as chemistry, pharmaceuticals, cosmetics, and electronics.

Analytical Balances

Analytical balances take precise measurements of small sample masses. Calibration helps users avoid drawing inaccurate conclusions if the device is out of tolerance. We also calibrate other metrological balances, including spring balances, portable balances, equal arm balances, and unequal arm balances.

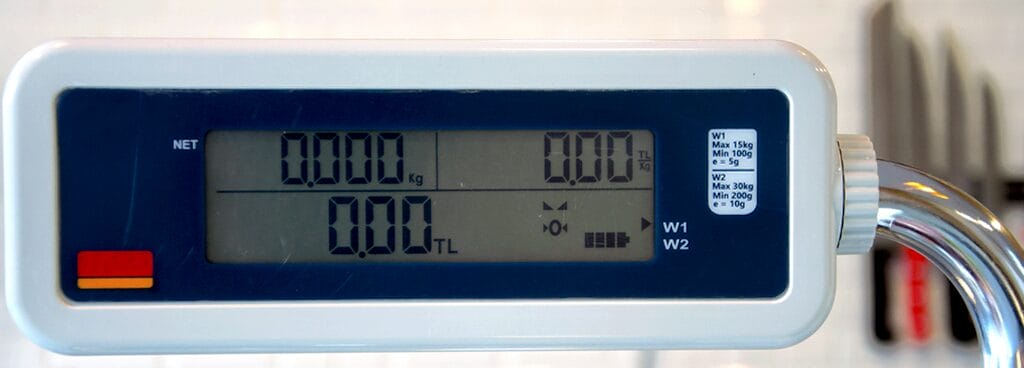

Precision Scales

Many professionals use precision scales for precise measurements of minute quantities. The high sensitivity of a precision scale enables close readings of liquids and solids, but even a slight deviation can introduce uncertainties. ATS calibrates precision scales capable of accuracy down to a fraction of a gram.

ATS Calibrates Large Scales

Platform and Floor Scales

We calibrate a wide range of platform and floor scales designed to weigh large objects, such as pallets, crates, and heavy boxes. The ATS calibration lab calibrates digital and floor scales up to 1,000 pounds. Platform and floor scales have applications in the following industries:

- Aerospace

- Automotive

- Construction

- Manufacturing

- Oil and Gas

- Shipping

Truck Scales

The ATS FoC calibrates multiple types of truck scales. A truck scale’s multiple load cells allows for a greater measurement range but also increases the need for frequent calibration. Industrial truck scale calibration is essential for accurate readings of vehicle weights to ensure trucks are adequately supplied and within regulatory weight requirements. Weight control is critical for safe transport over highways and bridges.

ATS Calibrates Crane Scales

We calibrate crane scales for weighing heavy suspended loads. Calibration helps ensure the scale maintains optimal performance according to manufacturer specifications. Following a regular calibration schedule is paramount for preventative maintenance and avoiding safety hazards associated with overloading, inaccurate measurements, and suspended overhead loads. The ATS calibration lab accepts crane scales measuring up to 100,000 pounds.

ISO/IEC 17025(2017) Accredited Labs

The ATS FoC unites dozens of high-performance companies under a single mission for customer satisfaction. Our labs maintain ISO/IEC 17025 accreditations in calibration procedures and mechanical, nondestructive, electrical, and chemical testing. Additionally, our services comply with 10 CFR 50 – Appendix B, 10 CFR Part 21, ASME NQA-1, ANSI/NCSL Z540-1, and ISO 9001:2015 requirements.

Clients can expect a standard turnaround rate of 7 to 10 business days. Devices shipped to our labs are given at least 24 hours to stabilize to ambient conditions:

- Temperature: 68 ˚F (+/- 1 ˚F)

- Relative Humidity: 30-55% RH

- Isolation joints in flooring to dampen vibrations

We typically calibrate scales and balances by comparing the device’s readings with a NIST-traceable reference scale or the known values of certified ASTM Class 1 and Class F weights across the scale’s full range.

Our technicians document the calibration procedure and NIST-traceability in a certificate of calibration available on iPortal, our secure web platform. Clients may also refer to iPortal for calibration schedules and equipment history.

Contact Us

Call +1 (888) 287-5227 or submit the request form on this page to schedule industrial scale calibration from the industry experts at ATS. Check our other calibration services on our website or call our representatives for more information.