- Home

- Services/IndustriesServicesindustries

- About Us

- LocationsStatesAccordion ContentAccordion ContentAccordion ContentAccordion Content

- Job Openings

- Quick Links

- ATS Family

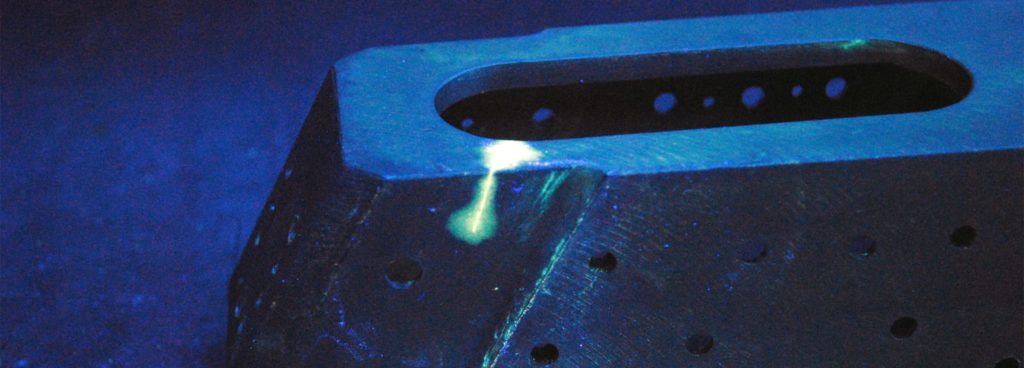

ATS' Dye Penetrant Testing Services

Applied Technical Services (ATS) implements one of the most proven inspection methods using dye penetrant testing. Our clients ask for this method since it is extremely receptive to small surface flaws and discontinuities. In addition, it is used on a wide-range of complex and intricate contours and materials ranging from metals, plastics or polymers, and composites. PT is a highly-demanded cost cutting measure to quickly inspect large-sized objects or a considerable amount of components.

By applying dye penetrant testing, our techs are certified to detect common and uncommon discontinuities exposed to the material’s surface. In most cases, the revealed findings are fatigue cracks, grinding cracks, quench cracks, impact fractures, overload fractures and weld discontinuities.

ATS’ certified team of NDT professional techs offer complete inspection services to an expansive range of industries domestically and globally. Dye Penetrant Testing services are offered in our laboratories, in the field and/or on client premises with customer service as a priority and cost effectiveness as a primary goal.

Common PT Findings:

- Fatigue Cracks

- Grinding Cracks

- Impact Fractures

- Laps

- Overload Fractures

- Porosity and Seams

- Quench Cracks

- Forging Defects

Common Materials Tested:

- Aluminum

- Ceramic Materials

- Glass

- Composites

- Nickel

- Plastic

- Rubber

- Stainless Steel

- Various Metals

Common PT Applications:

- Engine Parts

- Fan Blades

- Fillet Welds

- Forged Parts

- Inlet/Outlet Blowers

- In-Service Parts

- Pressure Bodies

- Stainless Steel

- Turbine Engines

- Valve Components

- Weld Inspections

Industries Using PT:

- Manufacturing

- Ship Yards

- Petrochemical

- Pharmaceutical

- Pipeline

- Power Generation

- Pupl and Paper

- Welding Fabrication

Request Form

"*" indicates required fields