- Home

- Services/IndustriesServicesindustries

- About Us

- LocationsStatesAccordion ContentAccordion ContentAccordion ContentAccordion Content

- Job Openings

- Quick Links

- ATS Family

High Stresses Demand High Durability

ATS offers pyroshock testing to help clients validate the durability of their components and subassemblies, verifying that they can withstand the extreme forces native to their intended use. While every manufacturer wants their product to be resilient for quality assurance and customer satisfaction, even the most robust of consumer products yield in the face of massive forces — primarily because they were never designed for such a service environment. Certain items, however, do require a higher level of durability to fulfill their purpose effectively. Equipment designed for use in aerospace, military, and other highly demanding service conditions must continue to perform adequately after sustaining a massive force such as a pyroshock. Any product that fails in the circumstances particular to their intended service conditions jeopardizes both the success of their task and the safety of their operator.

What is a Pyroshock?

Also referred to as a pyrotechnic shock, pyroshock is a type of force characterized by high frequencies and high magnitudes. Different from a ballistic shock in that it does not comprise projectile impacts, the most common example of a pyroshock is when an explosion- or propellant-activated device engages — launching a payload from the equipment’s main structure. This brief but intense stress can undermine the functionality of the affected subassembly, as these shocks can cause fatigue cracks to initiate in materials over time, exacerbate existing flaws, loosen fasteners, dislodge electronic components, or disrupt their signals due to electromagnetic emission. In the case of a satellite using a multi-stage launching sequence to propel itself into orbit, the boosters eject from the main rocket. If this process were to interrupt functioning of any of the delicate electronic instruments onboard for even a moment, the results could be catastrophic.

To ensure their products continue to operate at the highest capacity after undergoing these forces, clients send samples to ATS for pyroshock testing.

Pyroshock Testing and Relevant Standards

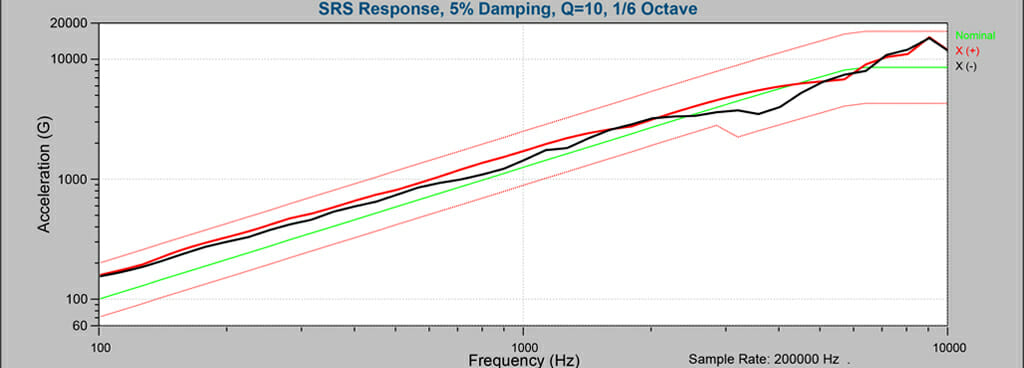

Testing samples using this method requires the ability to administer a significant mechanical shock. ATS accomplishes this in two ways — using either an electrodynamic shaker table or a tuned beam, excited by a hammer or air cannon. These advanced analytical tools allow our technicians to subject the unit under test to precise stresses mimicking those in its intended service environment, as we can apply impacts up to 20,000Hz and 100,000g. By implementing these methods, we can assess the sample’s durability without subjecting it to actual explosions.

We maintain an ISO 17025 accreditation through the A2LA to perform pyroshock testing to the following relevant standards:

- MIL-STD 810H

- MIL-STD 1512

- MIL-STD 1576

The ATS Difference

ATS offers a level of expertise and professionalism that clients prize. While we offer a variety of testing capabilities to other industries, our pyroshock testing almost exclusively serves the automotive, military, and aerospace industries. If your company needs this or another method of environmental testing, contact ATS today for a free quote!

Request Form

"*" indicates required fields