- Home

- Services/IndustriesServicesindustries

- About Us

- LocationsStatesAccordion ContentAccordion ContentAccordion ContentAccordion Content

- Job Openings

- Quick Links

- ATS Family

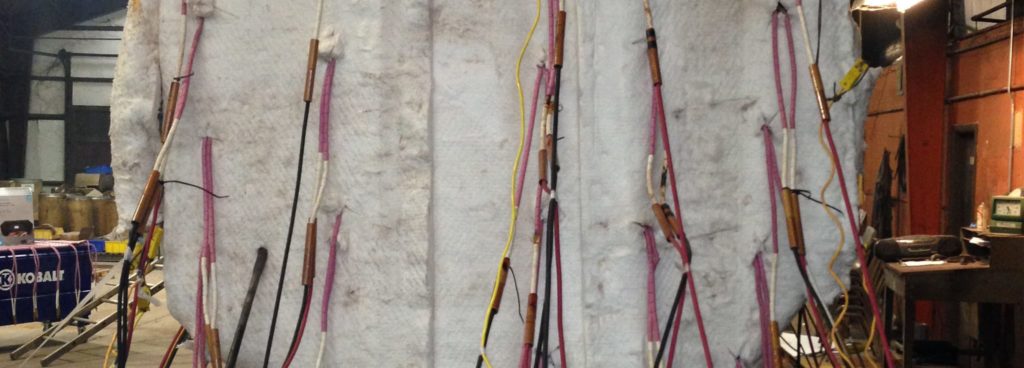

Weld Heat Treatment Services

As an industry leader in weld heat treatment companies, ATS offers high quality engineering, testing, and inspection services. We have earned an excellent reputation in customer service by adhering to safety standards, and offering a wide variety of services performed by professional/knowledgeable experts.

In response to high demand from many industries, ATS offers electrical resistance heat treatment services throughout the Southeast. This treatment will benefit many of our current and potential new clients who are in the process of receiving other ATS engineering, testing, and nondestructive inspection services.

Heat Treatment Objective & Method

Objective:

Heat Treating is the controlled heating and cooling of metals to alter their physical and mechanical properties without affecting the product’s shape. Noted benefits to this treatment are increasing the strength of the material, or achieving certain ease of manufacturing objectives such as improved machinability, formability, or restoring ductility after a cold working operation. In addition to the manufacturing benefits, many industries may rely on this process for better product performance due to increased strength and other desirable material property characteristics.

Method:

- ATS' equipment uses 480 volt three phase (high voltage) power to supply 6 circuits of 85 volt (low voltage) to power electric resistance heating pads

- Quality equipment and technology capable of heating from ambient to 2,400°F +

- Treatment accurately and efficiently performed with proper documentation according to stringent Quality Assurance Procedures and Standards

- Utilizes NIST-traceable recorders and thermocouples for accurate documentation

Why Pre & Post Weld Heat Treatment (PWHT)?

Benefits of Preheating:

The goal of preheating is to reduce the cooling rate of the base metal and deposited weld metal to avoid formation of detrimental phases.

Method:

- Uniform heat penetration

- Maintaining specific minimum temperatures

- Less downtime with components always ready to weld

- Welder productivity for faster turnarounds

- Eliminates detrimental manual preheat effects (rosebuds)

- Eliminates any open flames reducing a major SAFETY issue

- Recordable documentation of preheat

Benefits of Post Weld Heat Treatment:

Post Weld Heat Treatment or Stress Relief is a crucial step in maximizing the life of process equipment. PWHT tempers the metal and reduces residual stresses, minimizing the risk of brittle fracture, stress and corrosion cracking and initiation of potential fatigue cracks. This is especially important for equipment used in harsh service environments, such as Refiners and Utility Industries.

Common Industries We Serve:

- Refiners

- Utilities (Power)

- Chemical

- ASME Stamp Holders

- Code Shops

- Pipe or Tank Fabricators

- Pulp & Paper

- Forging Manufacturers

Request Form

"*" indicates required fields