- Home

- Services/IndustriesServicesindustries

- About Us

- LocationsStatesAccordion ContentAccordion ContentAccordion ContentAccordion Content

- Job Openings

- Quick Links

- ATS Family

Heat Treating Services

Applied Technical Services prides itself on its ability to offer not only the types of heat treating services that our customers are looking for but also the high quality engineering, testing and inspection services that they can depend on. We’ve worked hard in developing our excellent reputation in customer service and continue to strive to be an industry leader.

The types of heat treating services offered by ATS were designed to meet the high demands from many different industries, always adhering to stringent safety standards. All of our heat treating services are performed by dedicated and knowledgeable professionals, many of whom hold multiple accreditations and certifications between them.

Heat Treating Benefits

Heat treating commonly involves heating and cooling metals in such a way so as to alter their physical and mechanical properties without also changing their original shape. Heat treating is often used to increase the strength of a material or to help achieve certain product performance objectives.

The ATS Approach

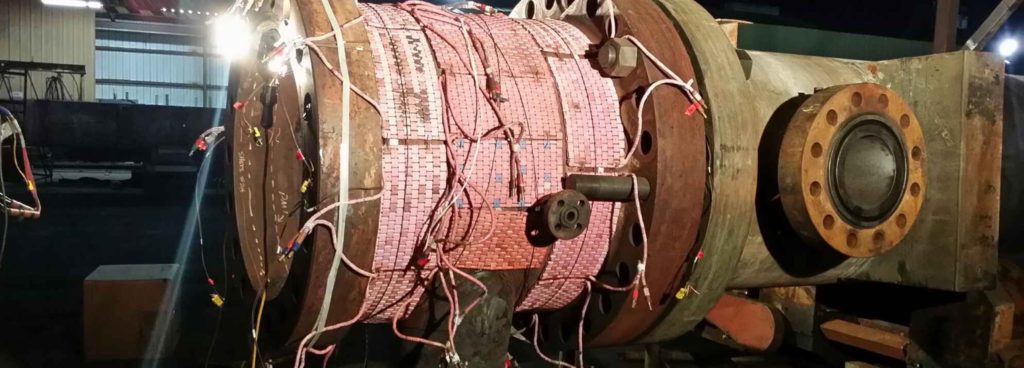

ATS’ heat treating services involve equipment that uses 480 volt three phase (otherwise known as high voltage) power to supply six different circuits of 85 volts. This is used to power the electric resistance heating pads. The type of equipment that we use during this process is capable of heating from ambient to 2,400°F or more depending on the needs. All of our heat treating services are accurately and efficiently performed using not only proper process documentation, but also the highest level of Quality Assurance Procedures and Standards available. We also utilize NIST traceable recorders, thermocouples and equipment for only the most accurate documentation.

The types of heat treatment services offered by ATS are used in a wide range of industries across the country, including but not limited to ones like:

- Utilities (Power)

- ASME Stamp Holders

- Code Shops (Welding Fabricators)

- Pipe or Tank Fabricator

- Pulp & Paper

- Forging Manufacturers

ATS also specializes in PWHT, or “Pre and Post Weld Heat Treatment.” Via a process of uniform heat penetration, specific minimum temperatures are therefore easier to maintain. The ultimate goal of this process is to reduce the cooling rate of both the deposited weld metal and the base metal with the added benefit of less downtown as components are always ready to weld. This, in turn, translates to increased productivity and faster turnarounds besides helping to eliminate any open flames that would commonly create a major safety issue in the workplace.

ATS' Quality Assurance

If your organization is looking for a trusted partner to handle any and all heat treating services that you may need, please don’t hesitate to contact Applied Technical Services today for more information.

Request Form

"*" indicates required fields