- Home

- Services/IndustriesServicesindustries

- About Us

- LocationsStatesAccordion ContentAccordion ContentAccordion ContentAccordion Content

- Job Openings

- Quick Links

- ATS Family

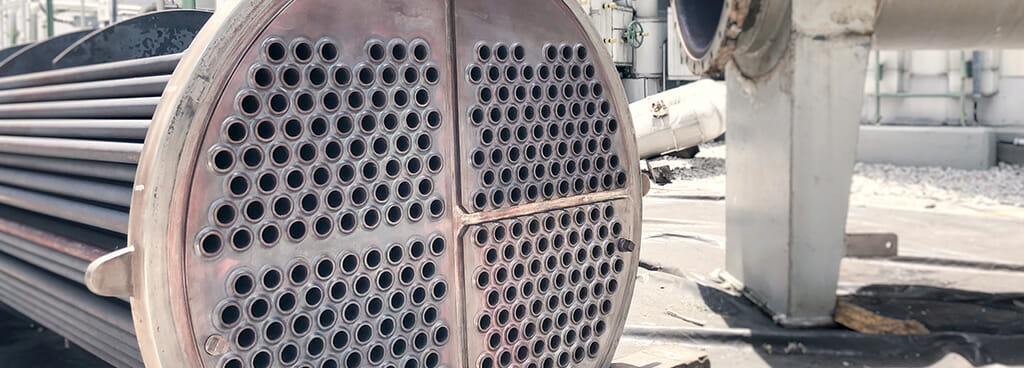

Heat Exchanger Testing Services

Applied Technical Services offers heat exchanger testing as part of our wide range of nondestructive testing services. Our NDT field technicians can thoroughly test heat exchanger tubes and verify that they operate safely in accordance with applicable codes and standards.

A Proactive Approach to Heat Exchanger Maintenance

Heat exchangers are used in the chemical, nuclear, wastewater treatment, and other plants to heat and cool industrial processes for improved efficiency. This temperature exchange is accomplished with the use of tubes that carry fluid through separate channels. However, heat exchanger tubes are frequently exposed to high fluid pressure and should be regularly tested to ensure satisfactory performance, efficiency, and safety.

Heat exchanger tubes can suffer cracking, pitting, general corrosion, and other types of surface and sub-surface flaws. If left unchecked, these flaws can deteriorate into larger issues and potentially result in compromised performance, operational failures, and unplanned shutdowns. For this reason, the best approach to heat exchanger maintenance is a proactive one.

Typical Heat Exchanger Testing Findings:

- Deposit Build-up

- Intergranular Corrosion

- Microbiologically Induced Corrosion

- Pitting Corrosion

- Stress Corrosion Cracking

- Thermal Fatigue

- Vibration Fatigue

Heat exchangers can vary from operation to operation; subsequently, there is no one “catch-all” test method to satisfy every circumstance. ATS can nondestructively test both ferromagnetic and non-ferromagnetic tubes using several proven NDT methods:

Used for non-ferromagnetic tubing, eddy current testing (ECT) detects and characterizes surface flaws such as cracking and voids. ECT creates a magnetic field with electricity and magnetism onto the conductive metal surface. Variations in the electrical conductivity readings typically indicate an irregularity.

Internal Rotary Inspection System (IRIS)

IRIS can be used to test the outside and interior diameter of both ferromagnetic and non-ferromagnetic heat exchanger tubes for corrosion. IRIS probes use rotating mirrors that send an ultrasonic pulse around a helical path to produce a scan and accurately measure wall thickness and metal loss.

Remote Field Testing (RFT)

Used for ferromagnetic tubing, RFT can be used to quickly assess tubes for thinning. The magnetic field will show distortions if there are flaws present.

ATS – Your NDT Provider

Applied Technical Services holds an excellent reputation for service quality, both nationally and internationally. As such, our services are performed according to stringent standards under our ISO certified quality management program. For more details about our heat exchanger testing services, contact us today. Our clients can expect helpful client support representatives, detailed reporting, and accurate results. ATS — We take a closer look!

Request Form

"*" indicates required fields