- Home

- Services/IndustriesServicesindustries

- About Us

- LocationsStatesAccordion ContentAccordion ContentAccordion ContentAccordion Content

- Job Openings

- Quick Links

- ATS Family

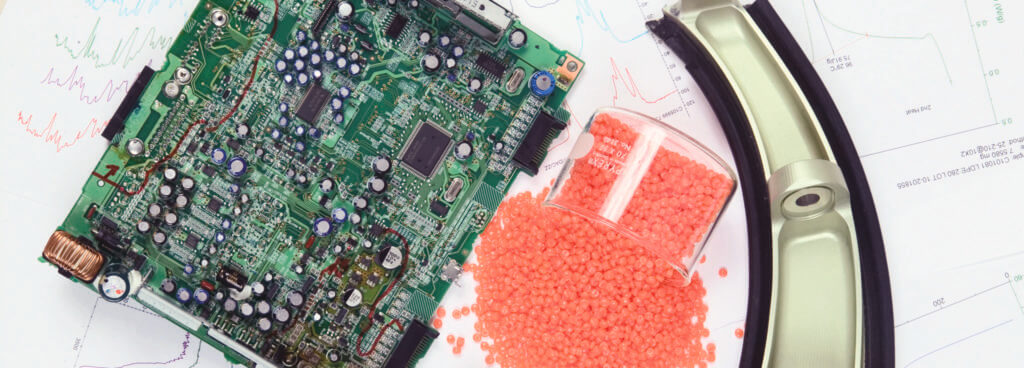

Polymer Testing Services

Applied Technical Services offers a variety of Polymer Testing Services, including polymer material testing, polymer fracture analysis, polymer characterization, polymer strength testing, polymer structure analysis, and polymer fatigue testing.

Polymer Strength Testing

Polymer Strength Testing is an effective, cost-efficient testing method used to determine the strength, resilience, physical capabilities, and structural characteristics of polymer-based materials and components. Strength testing a polymer can help to identify potential flaws in a test subject to ensure proper functionality and avoid product failure. Strength testing also provides detailed information regarding the sample’s expected lifespan and identifies weaknesses, allowing manufacturers to make adjustments and improvements early in the development phase. As there are many different methods used to analyze a polymer-based material’s strength, the most effective method is determined by the sample product’s intended use. For more information, click here.

Polymer Fatigue Testing

Due to polymer’s unique flexibility characteristics and molecular structure, performing fatigue testing for polymer-based materials is essential to verifying the sample’s resistance to external forces. There are several types of fatigue testing that incorporate different methods to analyze a polymer’s strength and characteristics. Testing the strength of a polymer allows manufacturers to identify expected product life cycle, verify industry compliance, and make quality improvements. For more information, click here.

Polymer Characterization

Polymer characterization is an in-depth analytical procedure that consists of closely examining the structure and composition of polymeric materials in order to verify structural integrity and identify flaws and weaknesses. Polymer characterization identifies several different material characteristics, including molecular mass, thermal stability, and mechanical properties. Polymer characterization is an efficient, cost-effective analysis method that serves many different purposes. For more information, click here.

Polymer Structure Analysis

Polymer Structure Analysis is used to closely examine and identify the structure and structural characteristics of a polymer-based sample product or component. Polymers are a highly utilized material due to their unique qualities, though there are several different factors of a polymer’s structure that need to be precisely calibrated in order to ensure the desired friction resistance, flexibility, strength, and durability. ATS conducts structure analysis of polymers to provide clients with a detailed, precise look at their products to ensure optimal performance and proper functionality. For more information, click here.

Polymer Fracture Analysis

Performing fracture analysis on a polymer involves analyzing a fractured polymer-based material in order to identify the characteristics and causes of the fracture. Polymers can fracture at low stress levels due to cyclic stress and fatigue, structural flaws, creep rupture, the presence of failure-inducing chemicals or agents, or long-term stress. There are several types of defects that can lead to the uneven distribution of stress and failure in polymer-based materials, such as crystalline boundaries, dislocations, and amorphous interlayers. Polymers possess a unique structure and require experienced polymer testing experts to ensure proper failure cause identification. For more information, click here.

Polymer and Polymer-based Material Testing

ATS’ Polymer Testing Services laboratories feature highly advanced equipment and are staffed by some of the nation’s leading chemists, engineers, and certified testing experts. These experts apply years of knowledge and experience to every test, committed to providing the highest level of customer satisfaction through detailed, reliable reporting. Our material testing experts strive to maximize the value of our testing services and minimize downtime by providing quick turnaround times. For more information, click here.

Testing and Analysis Standards and Specifications

In order to achieve the highest levels of accuracy and reliability, Applied Technical Services performs industrial testing in adherence with industry testing standards from several different entities. These organizations include but are not limited to:

- United States Department of Defense – DOD

- Radio Technical Commission for Aeronautics - RTCA

- American Association for Laboratory Accreditation - A2LA

- Registration, Evaluation, Authorization and Restriction of Chemicals – REACH (EU)

- Consumer Product Safety Commission - CPSC

- Society of Automotive Engineers - SAE

- Advanced Airlift Tactics Training Center - AATTC

- International Electrotechnical Commission - IEC

- National Institute of Standards and Technology – NIST

- The American Society for Testing and Materials – ASTM

- Institute of Electrical and Electronics Engineers - IEEE

- American National Standards Institute - ANSI

- International Organization for Standardization - ISO

- Environmental Protection Agency Standards - EPA

- The American Society of Mechanical Engineers - ASME

- German Institute for Standardization - DIN

- National Aerospace and Defense Contractors Accreditation Program - NADCAP

- The State of California - Proposition 65

ATS Quality Assurance: We Take a Closer Look

Applied Technical Services proudly serves several revered companies and corporations in the United States. Our internationally recognized quality assurance program has helped ATS establish ourselves as a leader in industrial testing, providing a consistent level of quality regardless of the type of service requested or the location at which the services are performed. As one of the longest-standing industrial testing providers in the United States, we understand the importance timeliness and efficiency, and we work diligently to help your business minimize downtime to keep operations running. From corrosion testing to pipeline inspections, our technicians and testing experts take a closer look to achieve the highest level of customer satisfaction possible. ATS serves clients in a wide range of industries, such as:

- Building and Construction

- Oil and Gas

- Aerospace and Aviation

- Renewable Energy

- Automotive

- Medical and Pharmaceutical

- Lighting and Electrical

- Consumer Products

- Military and Defense

- Pulp and Paper

- Food and Beverage

- Healthcare

- Nuclear

- Communication

- Power Generation

Applied Technical Services

Since our founding in 1967, ATS has worked hard to build and maintain our reputation as one of the nation’s leading industrial testing providers. Our expansive service network provides our clients with the added convenience of being able to schedule services at the location and time that suits their needs, and our longstanding business relationships serve as a testament to our commitment to customer satisfaction and quality. ATS holds ISO 17025 accreditations in several fields and is ISO 9001 certified, prioritizing the dependability of our reporting so your business can focus on doing what you do best. Contact the experts at Applied Technical Services and let us show just how convenient Polymer Testing Services can be. Click here or give us a call today at 1 (888) 287-5227 to request a free quote.

Request Form

"*" indicates required fields

Special Testing

- Hydrostatic Leak Testing

- Hydrostatic Pressure Testing

- Hydrostatic Testing

- Hydro Testing

- Leak Testing

- Load Testing

- Package Burst Testing

- Pipeline Hydro Testing

- Pipeline Hydrostatic Testing

- Pressure Cyclic Testing

- Pressure Decay Leak Testing

- Pressure Fatigue Resistance Test

- Pressure Fatigue Testing

- Pressure Leak Testing