- Home

- Services/IndustriesServicesindustries

- About Us

- LocationsStatesAccordion ContentAccordion ContentAccordion ContentAccordion Content

- Job Openings

- Quick Links

- ATS Family

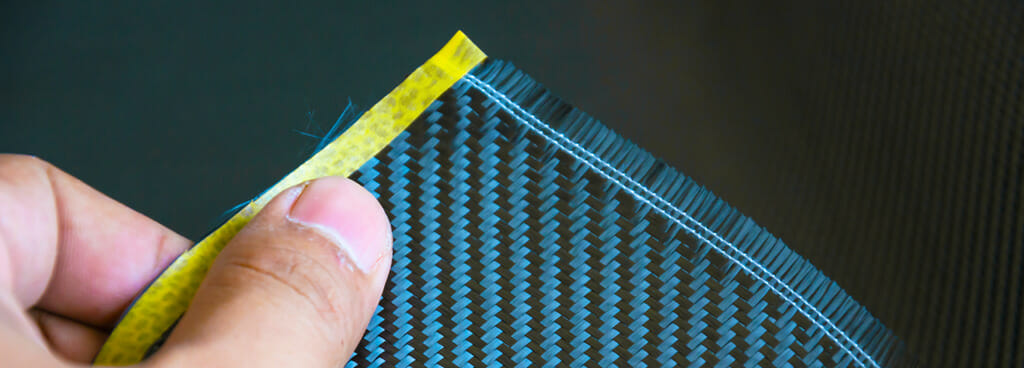

Fatigue Testing of Composite Materials

ATS offers fatigue testing of composite materials, enabling clients to make informed business decisions about product manufacture and purchase. Industries often use composite materials in critical structures and components, such as ship hulls and airframes, for increased strength and stiffness.

We frequently work with composite materials such as:

- Plywood

- Kevlar

- Reinforced concrete

- Fiberglass

- Carbon fiber-reinforced polymer

Fully Custom Testing

ATS can assess whether an item complies with industry standards, such as MIL-STD, ASTM, and CPSC. However, if a customer’s needs go beyond meeting industry standards, ATS offers fully custom testing services. We can shape our testing purposes and protocols to meet each client’s needs. For example, clients may request our services to learn more about a chosen material, including:

- Fatigue life

- Fiber direction and alignment

- Durability in environmental conditions

- Performance

- Structural and surface flaws

- Manufacturing defects

Some of our clients request testing on mass-produced components or products. Before a product enters circulation, a vendor may solicit a third-party tester, such as ATS, to ensure user safety. Our tests can prove the need for a design change or verify the product’s readiness for use.

We also handle critical components for the aerospace and defense industries. Certain aircraft components regularly undergo tens of thousands of pounds of pressure. To avoid a catastrophic failure and loss of life, plane manufacturers and component suppliers may use our fatigue testing to study materials in simulations of their intended environmental conditions. Manufacturers may request fatigue testing throughout a product or structure’s development and construction.

Clients may also request fatigue testing on composite materials as part of:

- Safety testing

- Failure analysis

- Performance testing

- Reliability testing

A common method of fatigue testing subjects a specimen to cyclic loading until the specimen breaks or fails, indicating how long an item can hold up to the forces in its intended use. We can also adjust the test variables to incorporate corrosive chemicals, humidity, and high temperatures to best represent real-life scenarios. ATS also offers other special testing services for fully custom procedures, including:

Lab Capabilities

ATS is proud to maintain an A2LA-accredited fatigue testing lab capable of simulating the intended environments for test specimens. We can raise temperatures to 1,000 degrees Celsius to test specimens under intense heat and apply forces between 2 pounds and 55 Kip to test specimens’ limits.

As an ITAR-certified company, ATS can perform rigorous tests on defense articles to assure manufacturers and suppliers that critical military equipment is able to withstand extreme conditions. We can maintain confidentiality as we test for code compliance, safety, and custom purposes.

About ATS

Applied Technical Services began in 1967 as a three-person engineering company based outside Atlanta, Georgia. Over fifty years later, we have built a Family of Companies across the United States that provides consulting engineering, calibration, inspection, and testing services to industrial and business clients.

Since our humble beginnings, we have promoted safe testing and thorough analysis to maintain our high-quality customer service. Our expert technicians strive to give clients prompt responses to all testing and inspection needs.

Our super lab is A2LA-certified to perform mechanical, nondestructive, electrical, chemical, and calibration testing. We also hold NADCAP certification for nondestructive and material testing. To learn more about our certifications and recognitions, click here.

Contact Us

Call +1 (888) 287-5227 or complete the request form on this page to schedule fatigue testing on your composite materials today.

Request Form

"*" indicates required fields

Special Testing

- Hydrostatic Leak Testing

- Hydrostatic Pressure Testing

- Hydrostatic Testing

- Hydro Testing

- Leak Testing

- Load Testing

- Package Burst Testing

- Pipeline Hydro Testing

- Pipeline Hydrostatic Testing

- Pressure Cyclic Testing

- Pressure Decay Leak Testing

- Pressure Fatigue Resistance Test

- Pressure Fatigue Testing

- Pressure Leak Testing