- Home

- Services/IndustriesServicesindustries

- About Us

- LocationsStatesAccordion ContentAccordion ContentAccordion ContentAccordion Content

- Job Openings

- Quick Links

- ATS Family

Fatigue Testing Services

ATS provides fatigue testing services to determine the integrity of critical components and structures. We serve a variety of industries and clients with speed and discretion.

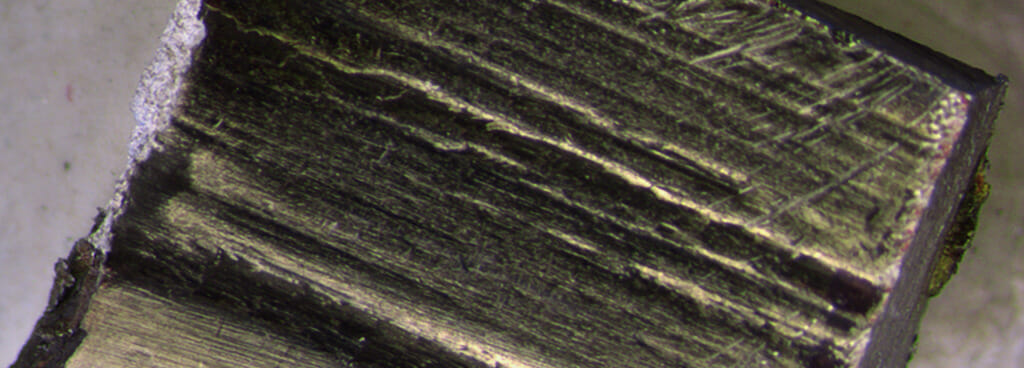

Fatigue begins when a crack forms due to fluctuating stress, typically near the surface. Over time, additional cracks propagate until the rest of the material cannot endure the stress, and the item fractures. However, the propagated cracks may not be visible until an item is near failure. When vulnerabilities and microcracks remain undetected, the effects can be dire.

Our Fatigue Tests

Fatigue tests identify weaknesses in materials so manufacturers and vendors can identify product defects before material fatigue becomes a liability. Fatigue testing uncovers vital information about a sample’s projected life and durability. Clients often use our analyses to identify the following about a chosen material:

- Fatigue life

- Fatigue strength

- Residual stresses

ATS offers multiple fatigue testing services to manufacturers, vendors, and end-users. Our expert technicians can test a material sample or perform a full-scale test on a product or structure. Clients may choose from a selection of services, such as:

- Corrosion fatigue testing

- Fatigue crack growth testing

- Spring fatigue testing

- Polymer fatigue testing

- Custom fatigue testing

We work with various materials and conditions to see how a sample holds up under loading and unloading forces. Upon request, we can subject materials to their intended environmental conditions, from to corrosive chemicals. Our fatigue testing machines can produce temperatures as high as 1000 degrees Celsius and a weight of up to 55 Kip.

Standard Certification and Custom Testing

Our lab technicians work with clients to verify that a material, product, or structure meets applicable standards or fully custom testing requirements. We can test for compliance with industry standards, such as:

Additionally, we can tailor the test concept and procedure to a client’s individual needs. Our special testing services allow for a broad range of mechanical testing capabilities.

Industries Served and ITAR Security

Our services empower a multitude of industry ventures and needs. Some of our regular clients include the following industries:

- Defense and military

- Consumer product manufacturing

- Construction

- Aerospace engineering

- Automotive engineering

- Medical device manufacturing

We are an ITAR-secure contractor that facilitates confidential testing and reports by qualified experts. Upon request, we can alter our procedures to adhere to ITAR specifications for testing items on the United States Munitions List (USML).

About Applied Technical Services

ATS began in 1967 as a three-person engineering company. Now, after over fifty years of operation, we have expanded our national presence to nearly all states. From our headquarters in Marietta, Georgia, we work with clients and businesses on a global scale to provide consulting engineering, calibrations, inspections, and testing services. Our growing Family of Companies allows us to support our clients in a greater capacity now more than ever.

Our company mission is to empower clients to make informed decisions based on our rigorous testing abilities and comprehensive reporting. We value client safety and satisfaction above all else, which is why our super laboratory has gained recognition from A2LA, NADCAP, and other industry organizations:

- ISO 9001:2015 Quality Management System

- Federal Aviation Administration repair station

- Consumer Product Safety Commission compliance

- ITAR-secure company

Our super lab maintains A2LA and NADCAP accreditations, ensuring quality services and results. We offer a variety of testing services, including electrical, mechanical, and nondestructive testing. To learn more about our accreditations and accomplishments, click here.

Contact Us

Call +1 (888) 287-5227 or complete the request form on this page to schedule fatigue testing services from our team today!

Request Form

"*" indicates required fields

Special Testing

- Hydrostatic Leak Testing

- Hydrostatic Pressure Testing

- Hydrostatic Testing

- Hydro Testing

- Leak Testing

- Load Testing

- Package Burst Testing

- Pipeline Hydro Testing

- Pipeline Hydrostatic Testing

- Pressure Cyclic Testing

- Pressure Decay Leak Testing

- Pressure Fatigue Resistance Test

- Pressure Fatigue Testing

- Pressure Leak Testing