- Home

- Services/IndustriesServicesindustries

- About Us

- LocationsStatesAccordion ContentAccordion ContentAccordion ContentAccordion Content

- Job Openings

- Quick Links

- ATS Family

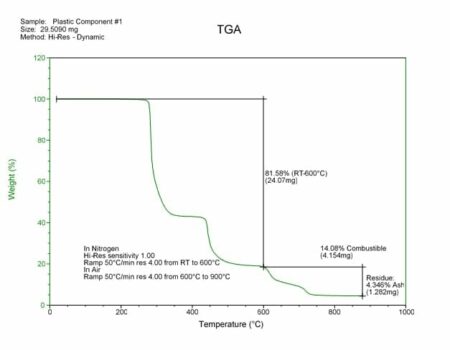

TGA Analysis

TGA analysis, also commonly referred to as thermogravimetric analysis, is a procedure that helps determine a number of different properties of a particular material such the amount of weight lost during heating and cooling, endothermic properties, and exothermic properties. Because of its comprehensive nature and overall versatility, it is often used to analyze a wide range of different materials including:

TGA analysis is a recommended component of a number of different ASTM and ISO standards, including ASTM E1131 and ISO 11358.

How The Method Works

At its core, TGA analysis is designed to provide your organization with a much deeper level of knowledge regarding the change in mass of a particular material as a function of both time and temperature. The basics involves heating a sample at a specific heating rate from ambient to 1000°C in nitrogen or air and then calculating the resulting weight losses that may be due to moisture, semi-volatile compounds, polymer degradation, carbon black, and ash content. The properties that are observed in a material are graphically displayed as a thermogram that shows the exact temperature where the sample has lost weight and appears as shown below:

ATS and TGA Analysis

Applied Technical Services’ TGA analysis services are performed by highly trained and educated professionals, many of whom hold multiple accreditations and certifications between them. Regardless of the type of material they’re working with or the particular client, the end goal is always the same and that is to provide your organization with a detailed level of information regarding the thermal behavior of materials to help with functions like research and development, production control, as well as failure analysis of field returns.

At Applied Technical Services, our primary goal always involves providing you with the comprehensive TGA analysis services that you need at an organizational level to make the strongest decisions possible moving forward. If your business is searching for a TGA analysis provider that can give you the comprehensive level of care and attention please feel free to contact Applied Technical Services today.

Request Form

"*" indicates required fields

Chemical Analysis

- Ash Testing

- Azo Dyes

- Azo Dye Testing

- Benzene Analysis

- Biocompatibility Testing for Medical Devices ISO 10993

- Chemical Composition Testing Lab

- Cleanliness Testing Lab

- Contamination Test

- Combustion Analysis

- CPSIA Testing Lab

- DSC Analysis

- DSC Analysis of Polymers

- DSC Polymer Characterization Analysis

- DSC Testing

- Ethylene Oxide GC MS Analysis

- EPA Method 24 Testing

- Extractables Leachables Testing

- Extractables Testing

- Flame Retardant Chemicals

- Formaldehyde Testing

- FTIR Analysis

- FTIR Chemical Analysis

- FT-IR Material Analysis

- FTIR Surface Analysis

- FTIR Testing

- Gas Chromatography Mass Spectrometer Analysis

- GCMS Analysis and Testing

- GCMS Oil Analysis

- Halide Anion Testing

- HPLC Analysis Services

- ICP-AES Analysis

- ICP-OES Testing

- ION Chromatography Testing

- ISO 10993 Testing

- ISO 10993 Testing Lab

- Karl Fischer Testing

- Leachable Testing

- LECO Testing

- Melting Point Analysis

- Methane Analysis Gas Chromatography

- Methanol Contamination Testing

- OES Materials Testing

- Optical Emission Spectroscopy

- PAH Testing

- Particle Size Distribution Analysis

- Particle Size Distribution Analysis Laboratory

- Particle Size Distribution Testing

- PFOA Testing

- PFOS/PFOA Testing

- Plastic Impact Testing

- Plastic Pipe Testing

- Polymer Characterization Lab

- Polymer Material Testing

- Polymer Testing and Analysis

- Powder Characterization

- Product Formulation

- Solvent Testing Lab

- TGA Analysis

- TGA DSC Analysis Lab

- TGA Moisture Analysis

- TGA Polymer Testing

- Thermal Analysis Services

- UV VIS Testing

- VDA 19.1 Cleanliness Testing Lab

- Ventilator Component Cleanliness Testing