- Home

- Services/IndustriesServicesindustries

- About Us

- LocationsStatesAccordion ContentAccordion ContentAccordion ContentAccordion Content

- Job Openings

- Quick Links

- ATS Family

Particle Size Distribution

Applied Technical Services performs particle size distribution testing to help clients qualify their samples for use. Companies that intend to use powders for industrial applications — such as powder metallurgy, injection molding, protective coatings, or additive manufacturing — find that one of the most important factors contributing to the success of their final product is the uniformity of their powders.

Importance of Particle Size Distribution and Testing

A subset of granular materials, powders are likewise made up of an immense number of individual particles. The main difference between them and other granular materials is that the particles that make up a powder are so extremely fine that they flow almost like a liquid when poured. Powders with highly uniform particles flow more freely, which allows them to settle more evenly. For most industrial applications, having tightly packed particles improves the physical performance characteristics of the end-product (e.g., the tensile strength of additively manufactured components). Conversely, highly irregular particles in a powder sample could undermine the efficacy of the component they are used to form. To ensure their powders have a beneficial powder size distribution, manufacturers send their samples to third-party testing labs like ATS.

Clients from a wide variety of industries send us their powder samples for a variety of applications. They may request this testing to help validate their powder production process or to perform quality control analysis on a failed product. Whatever the case, they know they can depend on ATS to give them the answers they need.

How the Method Works: Light Scattering / Laser Diffraction

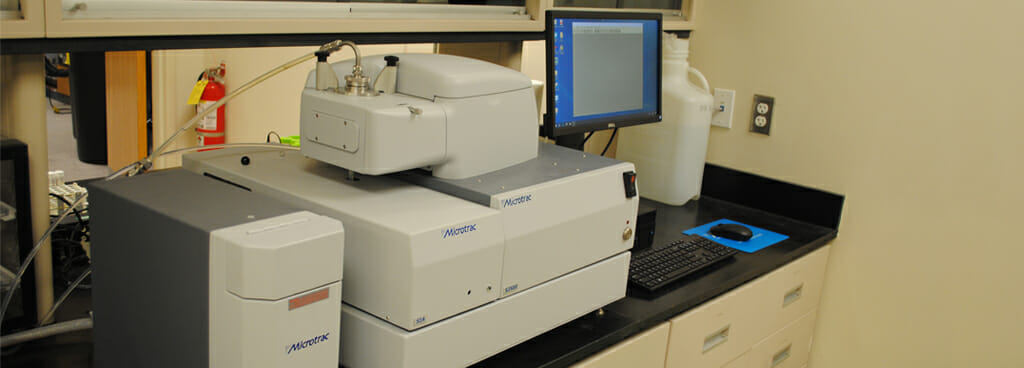

Our chemical analysis labs perform all our particle size distribution testing in accordance with applicable, recognized standards. They take their measurements using a method referred to as either light scattering or laser diffraction.

ATS chemists begin the process by introducing the sample to the particle analyzer. Depending on the material of the sample, they may suspend the analyte in a liquid medium (often water) or disperse it through a carrier gas. The analyzer will cycle the particles through the path of a laser, causing the light to scatter around them on their way to a focal point. Lined with detectors that measure the intensity and angle of the scattered light, the focal point feeds this data to the processor. At this point, the processor takes the information from each cycle and applies an algorithm to calculate the size of the corresponding particle. Then the process begins again. Our analyzer performs this analysis thousands of times on just as many particles in a matter of seconds.

The report yielded by this testing features a histogram laying out the number of particles in the sample of each size category across a broad range. Because of our chemists’ familiarity performing this method to relevant standards — namely ASTM B822, ISO 13320, and ASTM D4464 — and the sensitivity of the equipment they use to conduct the testing, our lab can measure particles ranging in size from 0.021 to 2800µm with a precision of 0.6% standard deviation.

About ATS

Applied Technical Services offers testing, inspection, and consulting engineering capabilities of peerless quality. Our company has grown immensely since our founding in 1967. In the last 50+ years, we have evolved from a team of three engineers working with local businesses out of our founder’s basement; nowadays, ATS represents a multidisciplinary firm employing over 1,000 experts in their respective fields — chemists and scientists, investigators and inspectors, calibrators and trainers, Professional Engineers and technicians — to answer the varied needs of clients operating around the globe. Although we cater to dozens of industries with our other chemical analysis services, our capacity as a trusted particle size distribution analysis provider primarily benefits the following:

- Power Generation

- Oil / Gas

- Manufacturing

- Defense / Military

- Communications

- Aerospace

- Additive Manufacturing

- Chemical

- Construction

- Healthcare / Medical

- Nuclear

- Powder Metallurgy

- Renewable Energy

On Our Commitment to Quality

ATS holds quality as a core value. To this end, we strictly abide by our ISO 9001-registered quality management system. Having achieved this distinction denotes that ISO-approved auditors observed our processes and verified that they comply with the internationally accepted standard outlining effective quality control practices for testing labs. Observing these principles helps us maintain accountability for and continually improve the quality of the services we provide. Having continuously maintained our ISO 9001-certified status since 2003 signifies to clients and our industry at large that we take quality quite seriously.

To ensure the best customer experience possible, ATS upholds several protocols when we perform services for our clients. First, our testing experts return detailed, accurate, and clear reporting. They do so in a short turnaround window that enables clients to make informed, timely decisions. Second, our customer service representatives work with clients who reach out regarding the status or results of their testing. Because we know customers sometimes have questions, these relationship specialists facilitate contact with relevant lab personnel. Third, our lab personnel remain accessible to clients reaching out for clarification. By being responsive to the customer’s needs and engaged in helping them find a solution, our lab experts keep clients informed and comfortable through the testing process.

If your company needs particle size distribution testing from a trusted provider, contact ATS today for a free quote — We take a closer look!

Request Form

"*" indicates required fields

Chemical Analysis

- Ash Testing

- Azo Dyes

- Azo Dye Testing

- Benzene Analysis

- Biocompatibility Testing for Medical Devices ISO 10993

- Chemical Composition Testing Lab

- Cleanliness Testing Lab

- Contamination Test

- Combustion Analysis

- CPSIA Testing Lab

- DSC Analysis

- DSC Analysis of Polymers

- DSC Polymer Characterization Analysis

- DSC Testing

- Ethylene Oxide GC MS Analysis

- EPA Method 24 Testing

- Extractables Leachables Testing

- Extractables Testing

- Flame Retardant Chemicals

- Formaldehyde Testing

- FTIR Analysis

- FTIR Chemical Analysis

- FT-IR Material Analysis

- FTIR Surface Analysis

- FTIR Testing

- Gas Chromatography Mass Spectrometer Analysis

- GCMS Analysis and Testing

- GCMS Oil Analysis

- Halide Anion Testing

- HPLC Analysis Services

- ICP-AES Analysis

- ICP-OES Testing

- ION Chromatography Testing

- ISO 10993 Testing

- ISO 10993 Testing Lab

- Karl Fischer Testing

- Leachable Testing

- LECO Testing

- Melting Point Analysis

- Methane Analysis Gas Chromatography

- Methanol Contamination Testing

- OES Materials Testing

- Optical Emission Spectroscopy

- PAH Testing

- Particle Size Distribution Analysis

- Particle Size Distribution Analysis Laboratory

- Particle Size Distribution Testing

- PFOA Testing

- PFOS/PFOA Testing

- Plastic Impact Testing

- Plastic Pipe Testing

- Polymer Characterization Lab

- Polymer Material Testing

- Polymer Testing and Analysis

- Powder Characterization

- Product Formulation

- Solvent Testing Lab

- TGA Analysis

- TGA DSC Analysis Lab

- TGA Moisture Analysis

- TGA Polymer Testing

- Thermal Analysis Services

- UV VIS Testing

- VDA 19.1 Cleanliness Testing Lab

- Ventilator Component Cleanliness Testing