- Home

- Services/IndustriesServicesindustries

- About Us

- LocationsStatesAccordion ContentAccordion ContentAccordion ContentAccordion Content

- Job Openings

- Quick Links

- ATS Family

Contamination Test

Applied Technical Services performs testing to a variety of chemical analysis methods, including several techniques to assist our clients with contamination test services. Nearly as important as the initial selection of design materials, verifying materials can greatly change the final product’s performance and success. Contaminants can change the composition (and thus characteristics) of the product and can undermine the performance of even the most artfully chosen materials. Manufacturers with a contamination problem can potentially see their products fail more often and more quickly than anticipated due to their design material’s compromised chemical or mechanical properties. As a result, production, quality, product performance, and sales may be negatively impacted.

Contamination testing labs such as ATS help clients verify materials and identify potential contaminants. With the insight our chemical analysis lab offers, companies can reformulate their product, change production methods, or carry on confidently to the assembly line as appropriate.

ATS' Most Commonly Requested Contamination Test Services

ATS utilizes several techniques (as needed) to identify contamination concerns. Contaminants can present themselves in a litany of ways, ranging from fibers to particles to stains to residues to odors. Our skilled chemists choose the most applicable method based on the material to be analyzed and the nature of the contamination. The chemical analysis lab employs the following methods and is ISO 17025 accredited by the A2LA to perform each of them to applicable standards where noted:

Useful for identifying contamination consisting of charged particles. In addition to being general contaminants, common anions, including chloride, sulfide, nitrate, nitrite, and fluoride can be precursors to corrosion and cause defects in electrical performance. Ion chromatography is an effective and sensitive instrumental technique that allows the separation and quantitation of ionic contamination. IC analysis requires a liquid sample; however, solid components can be measured for surface contamination by specialized rinsing and wiping techniques. IC can be combined with Parr oxygen bomb preparation to determine total contamination in certain solid matrices. IC is incredibly sensitive, allowing detection to part per billion (ppb) levels in some instances. This sensitivity makes it an ideal technique for contamination analyses.

Our lab is A2LA accredited to perform IC according to ASTM D4327.

SEM/EDS is a common initial test during contamination analyses. Since the elemental analysis is performed in conjunction with high magnification electron microscopy, it is particularly well suited for the analysis of particulate contamination and in situ analysis of site-specific contamination. SEM/EDS is ideal for those cases where a picture is worth a thousand words – high magnification imaging and detailed size measurements can be reported along with more complex data such as color-coded elemental mapping.

Our lab is A2LA accredited to perform SEM/EDS according to ASTM E1508.

ICP/AES is an especially flexible methodology, commonly used in analyzing metal, polymer, liquid, powder, and many other sample matrices. This makes ICP/AES analysis ideal for the evaluation of a variety of products for trace elemental evaluation. ICP/AES is the go-to method for determining lead content in consumer products and is equally suited to determine both the composition and the purity of raw materials. Liquid samples may be analyzed directly, while solid samples are digested with mixed acids to determine their elemental composition, including trace element contamination down to part per million (ppm) levels.

Our lab is A2LA accredited to perform ICP/AES according to ASTM E1479 and E1613.

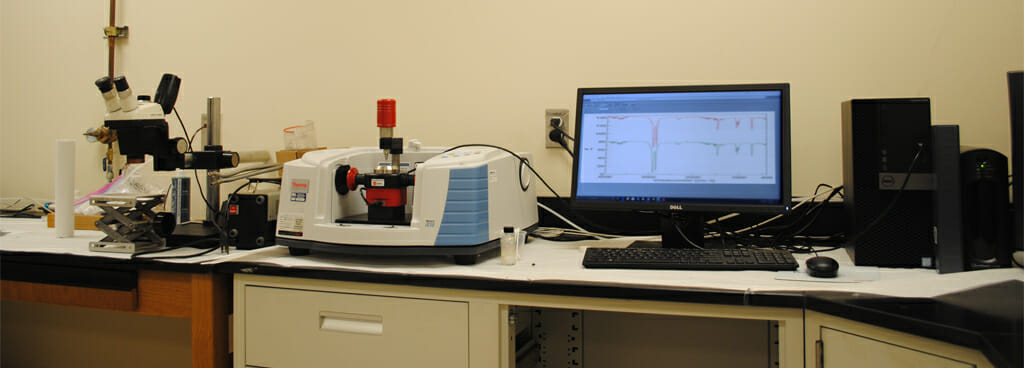

FTIR analysis is the go-to technique for identifying non-metallic contamination such as oil, grease, plastic, and rubber. FTIR allows comprehensive compound identification capabilities for these material types and is well suited to both the identification of complete unknowns and comparison of contaminants to suspected source materials. ATS can perform FTIR analysis by the standard transmission technique, by use of microscope, and via attenuated total reflectance (ATR). Analysis flexibility is critical in order to properly test and identify the vast majority of potential contaminants.

Our lab is A2LA accredited to perform FTIR according to ASTM E1252.

Other Relevant Methods

While clients typically request one of the tests above to detect and identify potential contaminants, the ATS chemical analysis labs can several other applicable methods when relevant to the client’s scope of testing. They include (but are not limited to) the following:

About ATS

Since our founding in 1967, Applied Technical Services has offered testing, inspection, and consulting engineering capabilities of the highest caliber. In the 50+ years since, we have grown abundantly; once a fledgling group of three engineers serving local businesses from our founder’s basement, ATS has become a multidisciplinary firm that employs several hundred chemists, technicians, scientists, investigators, inspectors, and Professional Engineers to serve clients operating in countries around the globe. Among the many we regularly serve, the following industries most benefit from our expertise in contamination testing:

- Additive Manufacturing

- Chemical

- Consumer Products

- Conventional Manufacturing

- Defense/Military

- Healthcare/Medical

- Insurance/Legal

- Nuclear

- Renewable Energy

Quality is Our Policy

ATS’ chemical analysis lab performs every contamination test according to our quality assurance program. We have registered our system with ISO 9001 to deliver a truly comprehensive customer service experience. This distinction means that an approved auditor affirms that our quality management system complies with the internationally recognized standard outlining effective quality assurance principles. By following these guidelines, ATS has primed itself to continually improve the quality of services that we provide. The time and effort needed to achieve and maintain this distinction signals to clients that we hold providing quality services to our valued customers as the foundation of good business practice.

We take a variety of measures to ensure our clients enjoy the best experience possible. First, we ensure our testing personnel return clear, accurate, and detailed reporting in a timely manner. We guarantee reliable data and analysis within a short turnaround window so that our clients can make timely decisions on the results of our testing. Second, ATS empowers our customer service personnel to receive contact from clients about the status or results of their testing. Each relationship ambassador directs customers to the most relevant testing expert and facilitates contact between the two parties. Finally, members of our lab staff assist clients with their needs. They remain accessible to customers reaching out, responsive to their questions and concerns, and engaged while helping them secure a solution to their problem.

If your company needs the services of a proven contamination testing provider, contact ATS today — We take a closer look!

Request Form

"*" indicates required fields

Chemical Analysis

- Ash Testing

- Azo Dyes

- Azo Dye Testing

- Benzene Analysis

- Biocompatibility Testing for Medical Devices ISO 10993

- Chemical Composition Testing Lab

- Cleanliness Testing Lab

- Contamination Test

- Combustion Analysis

- CPSIA Testing Lab

- DSC Analysis

- DSC Analysis of Polymers

- DSC Polymer Characterization Analysis

- DSC Testing

- Ethylene Oxide GC MS Analysis

- EPA Method 24 Testing

- Extractables Leachables Testing

- Extractables Testing

- Flame Retardant Chemicals

- Formaldehyde Testing

- FTIR Analysis

- FTIR Chemical Analysis

- FT-IR Material Analysis

- FTIR Surface Analysis

- FTIR Testing

- Gas Chromatography Mass Spectrometer Analysis

- GCMS Analysis and Testing

- GCMS Oil Analysis

- Halide Anion Testing

- HPLC Analysis Services

- ICP-AES Analysis

- ICP-OES Testing

- ION Chromatography Testing

- ISO 10993 Testing

- ISO 10993 Testing Lab

- Karl Fischer Testing

- Leachable Testing

- LECO Testing

- Melting Point Analysis

- Methane Analysis Gas Chromatography

- Methanol Contamination Testing

- OES Materials Testing

- Optical Emission Spectroscopy

- PAH Testing

- Particle Size Distribution Analysis

- Particle Size Distribution Analysis Laboratory

- Particle Size Distribution Testing

- PFOA Testing

- PFOS/PFOA Testing

- Plastic Impact Testing

- Plastic Pipe Testing

- Polymer Characterization Lab

- Polymer Material Testing

- Polymer Testing and Analysis

- Powder Characterization

- Product Formulation

- Solvent Testing Lab

- TGA Analysis

- TGA DSC Analysis Lab

- TGA Moisture Analysis

- TGA Polymer Testing

- Thermal Analysis Services

- UV VIS Testing

- VDA 19.1 Cleanliness Testing Lab

- Ventilator Component Cleanliness Testing