- Home

- Services/IndustriesServicesindustries

- About Us

- LocationsStatesAccordion ContentAccordion ContentAccordion ContentAccordion Content

- Job Openings

- Quick Links

- ATS Family

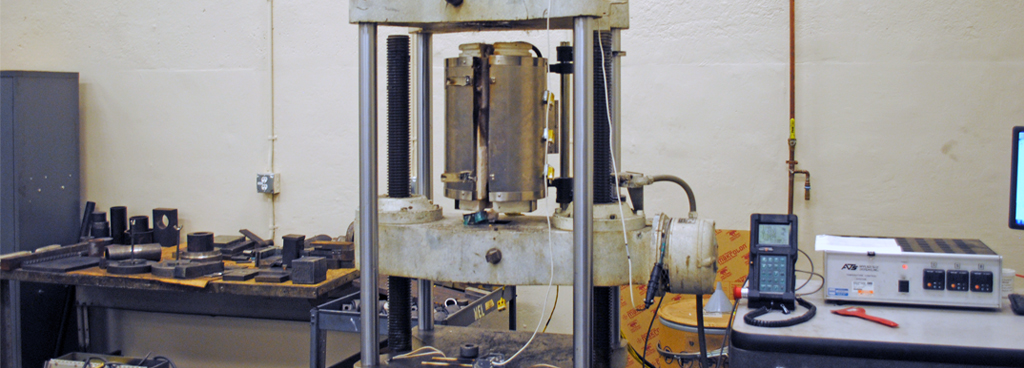

Hot Tensile Testing

ATS performs hot tensile testing, one of many types of analysis our tensile testing lab provides. Tensile testing examines several of a material’s behavior and mechanical properties. We regularly conduct tensile testing for many different materials, including:

- Composites

- Fasteners

- Metals

- Pipes

- Polymers

- Rebar

- Rubber

- Tubes

- Welds

Tensile testing can define several of a sample’s material qualities. To perform a tensile test, a calibrated testing machine grips a specimen and pulls it to failure in compliance with the applicable standard. Technicians can then plot the collected data on a stress-strain curve, allowing them to quantify certain material properties. If the material cannot withstand the necessary levels of stress, it may not be appropriate for a particular application.

The Hot Tensile Test

The hot tensile test combines tensile testing and high temperatures to analyze the effects of heat and strain on material properties and tensile strength. Many industries, especially automotive, power generation, and aerospace, need their products to withstand high heat conditions. Parts and components such as turbine blades, valves, and pistons endure high temperatures during service, so their materials need to be strong enough to tolerate those service conditions without taking damage.

The purpose of hot tensile testing is to evaluate the material’s thermal and mechanical characteristics, as well as to investigate material behavior such as changes in microstructure. The hot tensile test also provides a comparative measure of ductility between control and in-service materials. The test results and derived stress-strain curve help technicians identify the sample’s following characteristics:

- Area reduction

- Ductility

- Elastic limit

- Elongation

- Modulus of elasticity

- Proportional limit

- Tensile strength

- Ultimate strength

- Yield point

- Yield strength

Our advanced technology can test flat or round samples with precision temperature control. Our tensile and mechanical testing labs perform tests in compliance with several ASTM and ISO standards.

Our Testing Capabilities

The mechanical and tensile testing labs at ATS are ISO 17025 (A2LA) accredited for several tensile testing standards. Our labs have the capacity to test forces up to 400,000 pounds and temperatures up to 1800°F. Our experienced experts can develop custom evaluation plans for our clients’ materials. We also manage a machine shop in-house to prepare clients’ test samples or special equipment for use in unique testing setups.

ATS: Quality Service

Applied Technical Services is a leader in testing, inspections, and consulting engineering. We report detailed, accurate data within a quick turnaround. Our customer service ambassadors connect every client with the most relevant expert available to help solve their inquiry.

If you need hot tensile testing, contact ATS today.

Request Form

"*" indicates required fields

Mechanical Testing

- Accredited ASTM Lab

- ATSM Brinell Hardness Testing

- ASTM D1002

- ASTM E23 Charpy Impact Test

- ATSM Testing Lab

- ATSM Testing Services

- ASTM F519 Embrittlement Testing Services

- Bend Testing

- Bolt Tension Testing

- Charpy Impact Testing

- Charpy V Notch Testing

- CTOD Testing

- Drop Weight Testing

- Dynamic Tensile Testing

- Elevated Temperature Testing

- Hardness Testing

- High Speed Tensile Testing

- High Temperature Mechanical Testing

- High Temperature Tensile Testing

- Hot Tensile Testing

- Hydrogen Embrittlement Testing

- ISO 6892 Tensile Testing

- Izod Impact Testing

- Lap Shear Testing

- Load Testing

- Load Performance Testing

- Materials Lab Testing Services

- Materials Testing Company

- Mechanical Testing

- Mechanical Testing Certifications

- Mechanical Testing Lab

- Mechanical Testing Services

- Micro Tensile Testing

- Notched Weld Testing

- Plane Strain Fracture Toughness Testing

- Shear Strength Testing

- Shear Testing

- Strain Gauge Testing

- Tensile Coupon Testing

- Tensile Strength Testing

- Tensile Strength Testing Laboratory

- Tensile Testing

- Tensile Testing Lab

- Tensile Testing Metallurgical Lab

- Torque Testing

- Weld Procedure Qualifications

- Weld Testing

- Weld Testing Services

- WPS Qualified Welding Procedure