- Home

- Services/IndustriesServicesindustries

- About Us

- LocationsStatesAccordion ContentAccordion ContentAccordion ContentAccordion Content

- Job Openings

- Quick Links

- ATS Family

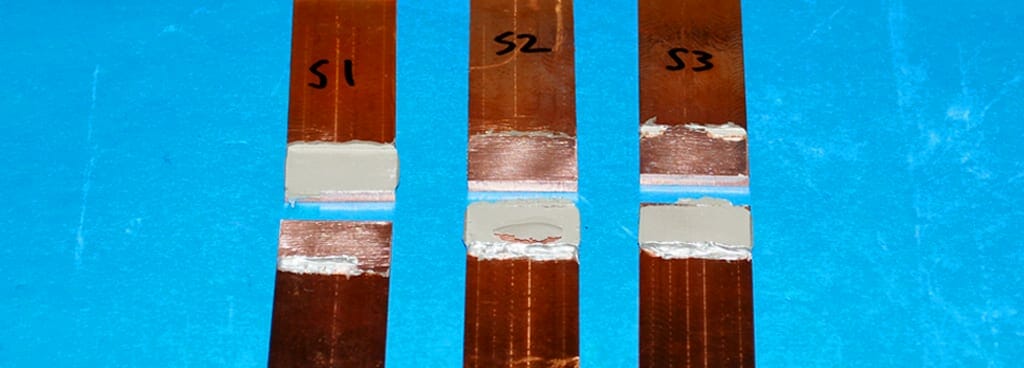

Shear Testing

Applied Technical Services provides shear testing to determine a product’s strength when exposed to shear loads. This particular test results in a sliding failure along a component’s plane that runs parallel with the direction of the force. Our mechanical testing lab determines the shear strength of a material by measuring the ultimate load reached before complete separation. Many manufacturers either research published values or conduct shear strength tests when determining what design and materials to use in building components.

Types of Materials Commonly Tested for Shear Strength:

- Adhesives

- Bonded Metals

- Composites

- Fasteners

- Films

- Plastics

- Pins

Standards and Regulations

Many industry standards have established shear testing recommendations as a guideline to determine if a product is fit for service. ATS’ technical experts are familiar with these applicable standards and test to them on a regular basis.

Shear Testing Standards:

- ASTM D732 — Shear Strength Test for Plastics

- ASTM D3846 — Shear Strength of Reinforced Plastics

- ASTM D2344 — Short Beam Shear Testing

- ASTM D3518 — Shear Response of Polymer Matrix Composite Materials

- ASTM D3164 — Shear by Tension Loading

- ASTM D1002 — Lap Shear Strength of Adhesively Bonded Material Specimens

- ASTM D3163 — Lap Shear Strength Test of Adhesively Bonded Plastics

- ASTM D5868 — Lap Shear Adhesion Test for Fiber Reinforced Plastics (FRP)

- ASTM F606 — Single Shear Test of Threaded Fasteners

- ISO 13445 — Block-Shear Method for Shear Strength of Adhesive Bonds between Rigid Substrates

- ISO 4587 — Tensile Lap-Shear Strength of Rigid-to-Rigid Bonded Assemblies

- NASM 1312-13 — Fastener Test Methods for Double Shear Tests

- NASM 1312-20 — Fastener Test Methods for Single Shear Tests

Customer Service and Quality Assurance

ATS is committed to providing exceptional customer service and high-quality testing. To fulfill this commitment, we have established an internal quality assurance program that ensures our processes comply with recognized quality system standards including ISO 9001:2015, 10 CFR 50 Appendix B, 10 CFR Part 21, ASME NQA-1 and ANSI/NCSL Z540-1. Our Engineers, Chemists, Scientists and Technical Experts are properly trained and/or certified to perform tests resulting in clear and accurate data in a timely manner. We serve clients nationally and internationally from a wide range of industries.

Request Form

"*" indicates required fields

Mechanical Testing

- Accredited ASTM Lab

- ATSM Brinell Hardness Testing

- ASTM D1002

- ASTM E23 Charpy Impact Test

- ATSM Testing Lab

- ATSM Testing Services

- ASTM F519 Embrittlement Testing Services

- Bend Testing

- Bolt Tension Testing

- Charpy Impact Testing

- Charpy V Notch Testing

- CTOD Testing

- Drop Weight Testing

- Dynamic Tensile Testing

- Elevated Temperature Testing

- Hardness Testing

- High Speed Tensile Testing

- High Temperature Mechanical Testing

- High Temperature Tensile Testing

- Hot Tensile Testing

- Hydrogen Embrittlement Testing

- ISO 6892 Tensile Testing

- Izod Impact Testing

- Lap Shear Testing

- Load Testing

- Load Performance Testing

- Materials Lab Testing Services

- Materials Testing Company

- Mechanical Testing

- Mechanical Testing Certifications

- Mechanical Testing Lab

- Mechanical Testing Services

- Micro Tensile Testing

- Notched Weld Testing

- Plane Strain Fracture Toughness Testing

- Shear Strength Testing

- Shear Testing

- Strain Gauge Testing

- Tensile Coupon Testing

- Tensile Strength Testing

- Tensile Strength Testing Laboratory

- Tensile Testing

- Tensile Testing Lab

- Tensile Testing Metallurgical Lab

- Tensile Testing Metallurgical Laboratory

- Tensile Testing Services

- Torque Testing

- Weld Procedure Qualifications

- Weld Testing

- Weld Testing Services

- WPS Qualified Welding Procedure