- Home

- Services/IndustriesServicesindustries

- About Us

- LocationsStatesAccordion ContentAccordion ContentAccordion ContentAccordion Content

- Job Openings

- Quick Links

- ATS Family

Purpose and Benefit of Bend Testing

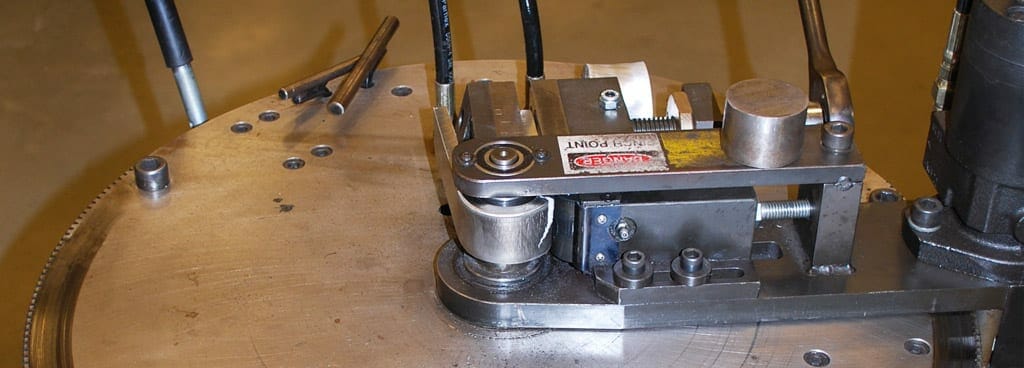

Bend testing is an easy qualitative test mostly and mainly used for the evaluation of both the material soundness and ductility. At Applied Technical Services, we frequently assess the quality of butt-welded joints using this method. The bend test is performed by using a sample coupon that is bent in three point bending to a specified angle.

Failure of a sample coupon is revealed on the exterior part of the bend when it is plastically deformed exposing weld defects or embrittlement of the material. A bend test is performed by wrapping a coupon around a mandrel of a specified diameter through a specified angle, and is the kind of test typically identified in a welding qualification specification and/or welder procedure. The bend angle may be from 90° to 180° depending on the requirements specified.

The diameter of the mandrel that the test specimen is bent over is identified in the test specification or standard and it differs with the material’s ductility and strength. When testing for welder qualification or for butt/groove welding procedure, sample may be oriented parallel or transverse to the welding direction. The transverse face bend specimen will disclose any defects on the face such as lack of sidewall fusion or excessive undercut close to the cap, opposite to the root bend in which it identifies lack of penetration or root fusion. There is also a side bend test, typically conducted on thicker materials.

Common Reasons to Request This Method:

- Welder Qualifications

- Procedure Qualification Requirements

- Material qualification or identification

- Tests can be performed on welds, base materials, and reinforcing bars

Performed to Following Standards:

- ASTM E190-92

- Various AWS Welding Codes

- BS EN 910

- ISO 9606 and 15614 Part 1

- ASME BPVC Section IX

- Numerous other Welding and Materials Specifications

Request Form

"*" indicates required fields

Mechanical Testing

- Accredited ASTM Lab

- ATSM Brinell Hardness Testing

- ASTM D1002

- ASTM E23 Charpy Impact Test

- ATSM Testing Lab

- ATSM Testing Services

- ASTM F519 Embrittlement Testing Services

- Bend Testing

- Bolt Tension Testing

- Charpy Impact Testing

- Charpy V Notch Testing

- CTOD Testing

- Drop Weight Testing

- Dynamic Tensile Testing

- Elevated Temperature Testing

- Hardness Testing

- High Speed Tensile Testing

- High Temperature Mechanical Testing

- High Temperature Tensile Testing

- Hot Tensile Testing

- Hydrogen Embrittlement Testing

- ISO 6892 Tensile Testing

- Izod Impact Testing

- Lap Shear Testing

- Load Testing

- Load Performance Testing

- Materials Lab Testing Services

- Materials Testing Company

- Mechanical Testing

- Mechanical Testing Certifications

- Mechanical Testing Lab

- Mechanical Testing Services

- Micro Tensile Testing

- Notched Weld Testing

- Plane Strain Fracture Toughness Testing

- Shear Strength Testing

- Shear Testing

- Strain Gauge Testing

- Tensile Coupon Testing

- Tensile Strength Testing

- Tensile Strength Testing Laboratory

- Tensile Testing

- Tensile Testing Lab

- Tensile Testing Metallurgical Lab

- Torque Testing

- Weld Procedure Qualifications

- Weld Testing

- Weld Testing Services

- WPS Qualified Welding Procedure