- Home

- Services/IndustriesServicesindustries

- About Us

- LocationsStatesAccordion ContentAccordion ContentAccordion ContentAccordion Content

- Job Openings

- Quick Links

- ATS Family

What is Materials Testing?

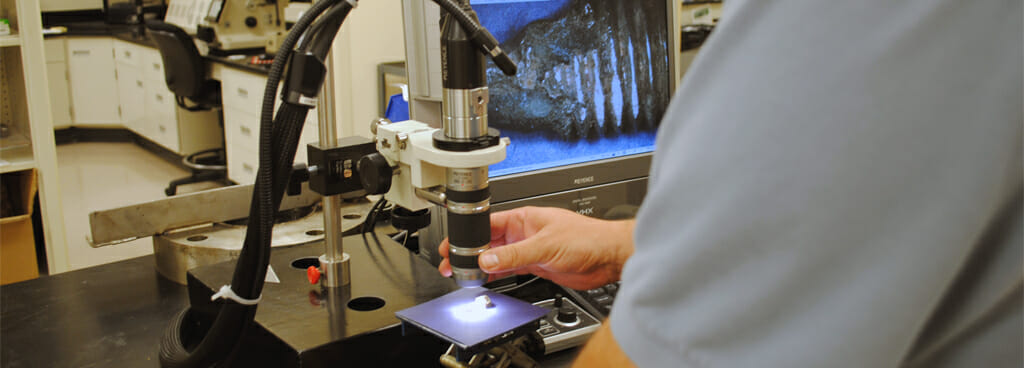

Applied Technical Services’ materials testing labs perform an extensive array of methods to help clients verify the characteristics of their samples. For most third-party testing labs, materials testing represents a diverse class of services. To illustrate, ATS’ materials testing department consists of several different branches of analysis, including environmental, mechanical, electrical, metallurgical, failure analysis, and forensic testing. Similarly, testing services may occur in-lab or on the client’s jobsite, depending on the scope of their needs. Furthermore, clients may request materials testing for several applications, ranging from material qualification to failure analysis to compliance testing.

Differences abound, but the common feature between this variety of methods is their focus: characterizing the physical (as opposed to chemical) traits of a material sample.

ATS' Capabilities

ATS sorts its materials testing capabilities between several of our in-house labs according to the goal of each method. Every lab offers an abundance of materials testing methods, performed by technicians with significant experience in performing them to relevant standards and specifications. In fact, our Marietta office maintains ISO 17025 accreditation through the A2LA to perform many of the following tests to commonly requested standards.

Environmental Testing: exposing samples to one or more non-mechanical stimuli that the finished product must survive in routine or otherwise reasonable service conditions.

Mechanical Testing: subjecting samples to physical pressures and stresses to determine the suitability of the test material for use in production.

Electrical Testing: testing the performance of in-service electrical components to determine their soundness and nonfunctioning components to determine the cause of failure.

Metallurgical Testing: inspecting a material sample to understand its structure and how that impacts its performance qualities.

- Elmendorf Tear

- Metallography

- Intergranular Corrosion

- Barcol / Brinell / Leeb / Webster Hardness

- Rockwell / Superficial Rockwell Hardness

Failure Analysis: assessing the material of a broken component for indications that allow technicians to determine the root cause of failure and develop a plan for prevention going forward.

Forensic Analysis: establishing the facts behind disputed events, determining the cause of accidents, providing expert testimony in court proceedings, and otherwise facilitating the legal process through testing.

Computed Tomography: using CT technology to nondestructively scan both the interior and exterior of a component — useful for finding manufacturing defects, performing first article inspections, and reverse engineering.

About Us

Applied Technical Services has been in business since 1967. We are a multidisciplinary firm that offers a vast amount of services, primarily categorized as testing, inspections, training, and consulting engineering. ATS has grown tremendously in the 50+ years since our humble beginnings in our founder’s basement. Today, over 1,000 ATS technicians, inspectors, chemists, scientists, investigators, Professional Engineers, calibrators, and trainers offer their services to answer the needs of clients from dozens of industries and who operate in countries across the world. Although we work alongside other industries in other capacities, those who benefit from our excellence in materials testing include:

- Aerospace / Aviation

- Automotive

- Chemical

- Communications

- Consumer Products

- Defense / Military

- Healthcare / Medical

- Insurance / Legal

- Manufacturing

- Nuclear

- Oil & Gas

If your company needs the services of a reliable materials testing lab, contact ATS today for a free quote — We take a closer look!

Request Form

"*" indicates required fields