The Applied Technical Services Family of Companies (FoC) uses the ASTM A262 testing standard to determine the likelihood of intergranular attacks in austenitic stainless steel materials.

Austenitic stainless steel is the largest and most diverse group of stainless steels, revered for its corrosion resistance, durability, and strength. They’re popular in the automotive, construction, aerospace, and power generation industries. Our A2LA-accredited lab evaluates these materials, ensuring they perform as expected and don’t prove to be overly prone to corrosion.

What is ASTM A262?

The American Society for Testing and Materials developed ASTM A262 as an outline for experts measuring a stainless steel material’s susceptibility to intergranular attack. Intergranular attacks are highly corrosive and weaken grain boundaries, compromising the material’s physical and mechanical properties.

The standard features the following five intergranular corrosion tests:

- The Oxalic Acid Test (Practice A)

- The Streicher Test (Practice B)

- The Huey Test (Practice C)

- The Streicher Test (Practice D)

- The Strauss (Practice E)

- The Copper Sulfate Test (Practice F)

Each of the aforementioned tests has unique elements and simulates specific corrosive conditions and environments.

Our ASTM-Compliant Corrosion Testing Services

Our metallurgy lab offers a wide range of important corrosion testing services that help ensure that our clients’ products and materials have the integrity needed to excel at specific tasks or in specific environments. We offer intergranular corrosion tests that comply with numerous ASTM standards, including, but not limited to the following:

- ASTM A262

- ASTM G110

- ASTM F2111

Our corrosion testing expertise also extends to the following types of corrosion tests:

- Corrosion Fatigue Testing

- Crevice Corrosion Testing

- Graphitic Corrosion Testing

- Microbiologically Influenced Corrosion

- Stress Corrosion Cracking

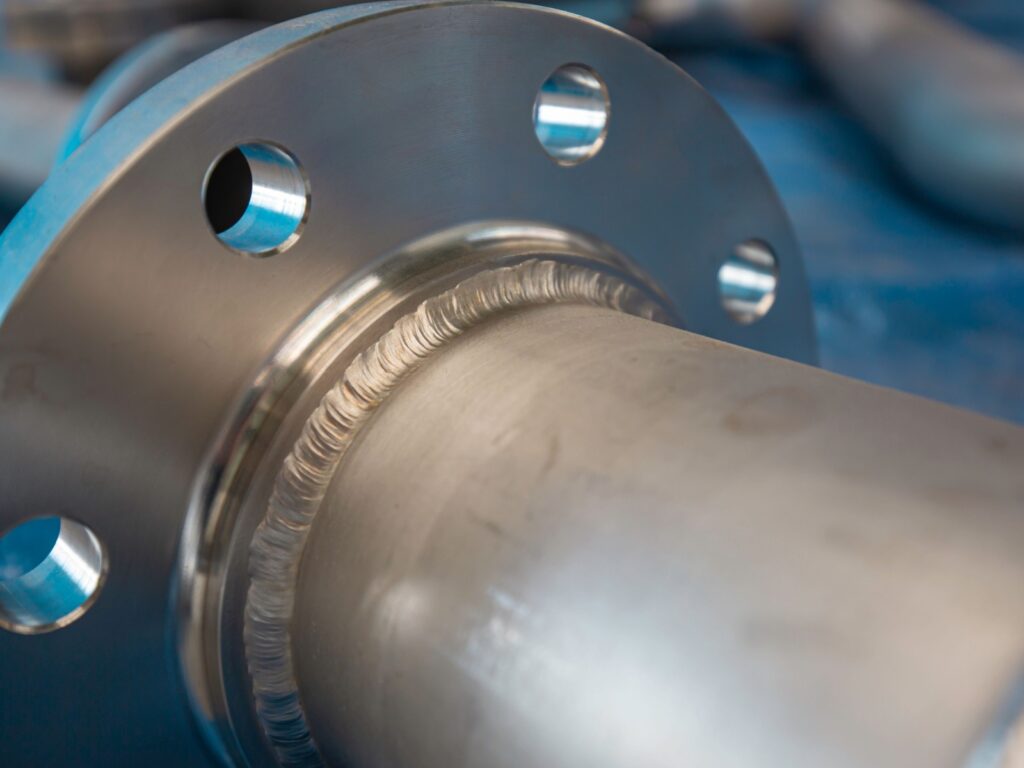

- Weld Corrosion

Understanding the Risks of Intergranular Attacks

Intergranular attack is very dangerous and especially concerning because it is not often easily noticeable until extensive damage has taken place. Over time this damage has deeply damaging effects on a material, often making it unsafe and unfit for use. Intergranular attack can cause a material to weaken and age prematurely, leading to increased repair and replacement expenses.

Contact Us

Please call +1 (888) 287-5227 for more information about how our accredited lab can help your company maintain product quality, comply with regulations, and grow toward a brighter future.