- Home

- Services/IndustriesServicesindustries

- About Us

- LocationsStatesAccordion ContentAccordion ContentAccordion ContentAccordion Content

- Job Openings

- Quick Links

- ATS Family

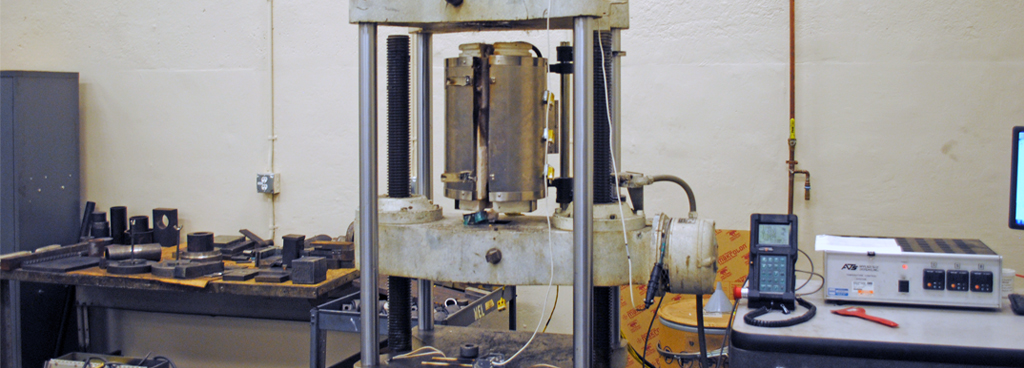

Applied Technical Services offers comprehensive tensile coupon testing through our tensile testing laboratories. We have the capabilities to provide polymer coupon testing, steel/metals coupon testing, and ceramic coupon testing. Our experts can report on common characteristics such as percent elongation, yield strength, tensile strength, and reduction of area. All tensile coupon testing is performed to relevant standards and client specifications.

What is a Coupon?

A coupon is a small sample of a more extensive test material. Testing larger materials or products can prove to be expensive and complex; therefore, tensile coupon testing is an effective and cheaper alternative. Technicians prepare the sample piece in a way that its properties are representative of the whole material. Tensile coupon testing is essential to ensuring the integrity of a product is up to relevant standards. In some cases, multiple coupons must undergo testing to provide margins of error in the case of material differences. ATS meticulously prepares coupons because external stimuli that would not affect the larger material may drastically impact the coupon.

Tensile Testing Capabilities

The ATS tensile testing laboratory provides a litany of additional tensile testing services. Using uniaxial machines, our technicians can offer the following test methods:

The tensile lab performs these tests on a regular basis and, as such, have experience testing a wide range of materials, including:

- Metals

- Tubes

- Rebar

- Pipes

- Composites

- Plastics

- Metal Wire

- Rubber

- Welds

- Fasteners

Additionally, our polymer and mechanical testing labs house cutting-edge technology to provide our clients with reliable results. Our polymer laboratory has a maximum force capacity of 20,000lbs and a temperature range from -19°F to 662°F (-70°C to 350°C) and our mechanical testing laboratory has a maximum force capacity of 400,000lbs with a maximum temperature of 1832°F.

ATS Quality Assurance

Applied Technical Services has been a global leader in testing and inspection services for more than 50 years. Thanks to our corporate management system, accredited to ISO 9001, our employees are dedicated to providing the best care to our clients. Our team of experts and technicians offers accurate and reliable reporting with quick return times. Request a free quote today for your tensile coupon testing needs. At Applied Technical Services, We Take a Closer Look!

Request Form

"*" indicates required fields

Mechanical Testing

- Accredited ASTM Lab

- ATSM Brinell Hardness Testing

- ASTM D1002

- ASTM E23 Charpy Impact Test

- ATSM Testing Lab

- ATSM Testing Services

- ASTM F519 Embrittlement Testing Services

- Bend Testing

- Bolt Tension Testing

- Charpy Impact Testing

- Charpy V Notch Testing

- CTOD Testing

- Drop Weight Testing

- Dynamic Tensile Testing

- Elevated Temperature Testing

- Hardness Testing

- High Speed Tensile Testing

- High Temperature Mechanical Testing

- High Temperature Tensile Testing

- Hot Tensile Testing

- Hydrogen Embrittlement Testing

- ISO 6892 Tensile Testing

- Izod Impact Testing

- Lap Shear Testing

- Load Testing

- Load Performance Testing

- Materials Lab Testing Services

- Materials Testing Company

- Mechanical Testing

- Mechanical Testing Certifications

- Mechanical Testing Lab

- Mechanical Testing Services

- Micro Tensile Testing

- Notched Weld Testing

- Plane Strain Fracture Toughness Testing

- Shear Strength Testing

- Shear Strength Testing Services

- Shear Testing

- Strain Gauge Services

- Strain Gauge Testing

- Tensile Coupon Testing

- Tensile Strength Testing

- Tensile Strength Testing Laboratory

- Tensile Testing

- Tensile Testing Lab

- Tensile Testing Metallurgical Lab

- Tensile Testing Metallurgical Laboratory

- Tensile Testing Services

- Torque Testing

- Weld Procedure Qualifications

- Weld Testing

- Weld Testing Services

- WPS Qualified Welding Procedure