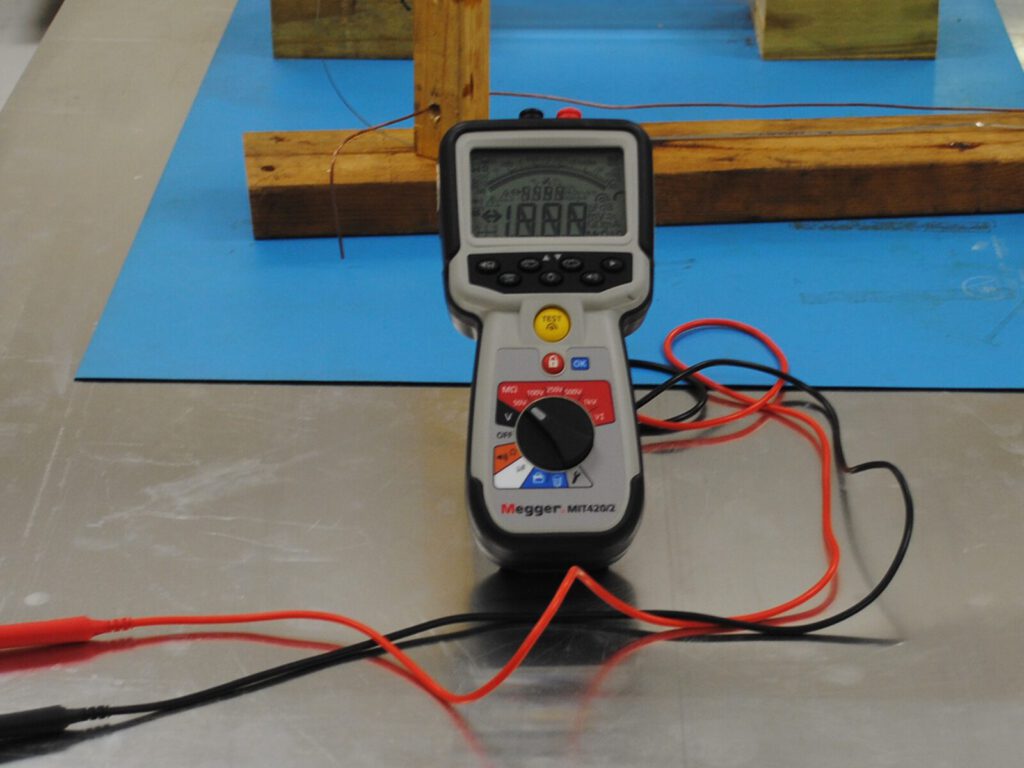

Insulators must be able to withstand the voltage levels they would experience during service to prevent material damage and human injury. Dielectric strength testing measures the durability of insulation materials for electronic devices.

What Influences Dielectric Strength?

A product must undergo dielectric testing to meet electrical safety testing standards. This kind of testing measures the point of failure in a material: when dielectric breakdown or electric discharge occurs through the material. Dielectric strength is measured in voltage per unit thickness, as the thickness of the material greatly impacts its strength.

Temperature impacts dielectric strength. Higher temperatures generally weaken an insulator’s resistance to dielectric breakdown.

Additionally, mechanical stresses can lower dielectric strength; mechanically loading insulation materials may reveal internal flaws that function as leakage paths for electric discharge.

Finally, fabrication details, such as weld lines in injection molding, flow lines in compression molding, or almost imperceptible flaws in plastic, serve as paths of least resistance for discharge to leak through.

With so many variables affecting dielectric strength, testing the insulator material’s strength is essential.

Industry Applications

Dielectric testing benefits the following industries:

- Aviation

- Metal fabrication

- Railroad

- Automotive

- Power generation

- Polymer/Plastics

- Lighting

- Power transmission

- Solar

ASTM D149 Standard Testing

The ASTM D149 standard involves the dielectric testing of solid electrical insulating materials at commercial power frequencies. ASTM D149 tests dielectric strength between 25 and 800 Hz, typically at 60 Hz if not otherwise specified. This test determines the breakdown voltage through the thickness of the test material.

At ATS, our electrical testing lab often inspects insulators, as well as wires, cables, batteries, lights, circuit breakers, connectors, and other products. We perform electrical testing to the ASTM D149 standard, among other ASTM, MIL-STD, ANSI, IEEE, and IEC standards. We verify product performance and determine causes for electrical failure.

Reliable Service from ATS

Applied Technical Services has provided inspection and testing services for over 50 years. We serve clients worldwide in several industries, including chemical analysis, metallurgy, non-destructive testing, fire investigation, equipment calibration, and materials testing.

ATS is dedicated to continually improving customer experience. Our personnel are skilled and experienced in their fields, striving to deliver clear and accurate results within a short timeframe. Our customer service ambassadors are available to connect clients to the most relevant staff members for their questions.

Contact Us

If you could benefit from dielectric strength ASTM D149 testing, contact ATS today.