- Home

- Services/IndustriesServicesindustries

- About Us

- LocationsStatesAccordion ContentAccordion ContentAccordion ContentAccordion Content

- Job Openings

- Quick Links

- ATS Family

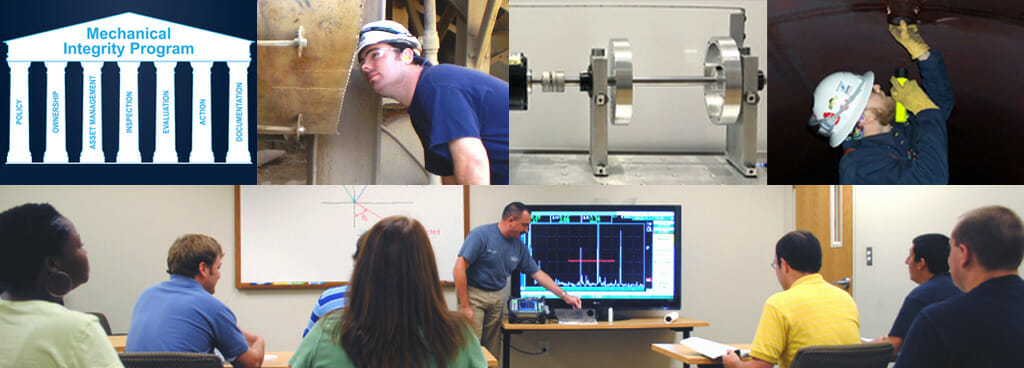

Reliability Engineering Training

To maintain their professional certification and licenses, engineers and inspectors may need to complete reliability engineering training provided by their employers or a third party. As a leading provider of inspections and consulting engineering, ATS employs qualified field experts with years of experience beneficial to reliability training.

Professionals can attend a scheduled public training service at an ATS location or schedule a private course at their own work facilities. Upon completing the course, they earn a documented certificate of completion that counts for professional development hours.

Mechanical Integrity Training

The American Petroleum Institute (API) will update its requirements for API 510, 570, and 653 inspection recertification between 2022 and 2025. Professionals whose certifications expire after January 1st, 2023, must complete 8 hours of Continuing Professional Development (CPD) within three years, along with meeting the existing requirements for recertification.

This course conveniently lasts a single day, so participants can quickly demonstrate their acquired knowledge. Instructed on-site by an ATS professional, the course concludes with a comprehensive exam. This course counts as eight CPD hours upon completion.

Mechanical integrity training covers various inspection methods, including:

- Dye penetrant testing

- Magnetic particle testing

- Radiographic testing

- UT thickness testing

- Visual inspections

The training course introduces professionals to mechanical integrity concepts, their applicable standards and regulations, and NDT nomenclature. The class also explores several approaches to mechanical integrity:

- Risk-based inspections (RBI)

- Condition assessments

- Damage mechanisms

- Weld repair

- Over-pressure protection

Attendees benefit from hands-on learning and real-world applications, such as selecting an appropriate inspection method and prioritizing a response. Additionally, professionals will learn tank layouts and Steel Tank Institute (STI) categories, understand ASME-based U-1 forms for pressure vessels, and how to calculate Tmin. This course also instructs professionals on OSHA’s process safety management (PSM).

Click here to schedule a Mechanical Integrity course.

Condition Monitoring Training

Effective condition monitoring allows personnel to catch machinery issues before they develop into significant damage or cause downtime. This cost-saving predictive maintenance contributes to more efficient and longer-lasting machine performance. The machinery monitoring and diagnostic course is available to engineers, technicians, mechanics, and supervisors over a 3-day period.

This course teaches professions how to:

- Identify and prioritize a response to machinery failure

- Select and operate condition monitoring and diagnostic tools

- Perform visual assessments of machinery installations and installation plans

- Assess diagnostic data according to client specifications and industry codes and standards

- Follow ATS methods for data evaluations

- Prioritize, execute, and report various corrective actions for defects

Click here to schedule a condition monitoring course.

Failure Analysis Training

We offer failure analysis courses for engineers, maintenance mechanics, and supervisors. Throughout the 3-day course, a professional engineer or reliability expert from ATS covers a training curriculum centered on diagnosing and preventing mechanical failures.

The course delivers a practical approach to failure analysis training that can be tailored to industrial plant professionals. Our instructors are industry experts and professional engineers who impart their knowledge and experience when covering:

- Mechanical component function

- Reliable operation factors

- Mechanical failure causes

- Diagnosing mechanical failures

- Preventing mechanical failures

Click here to schedule a failure analysis course.

Contact Us

Complete the request form on this page or call +1 (888) 287-5227 to schedule a private reliability engineering training course. Don’t miss an opportunity to gain experience and industry certification from seasoned professionals!

Request Form

"*" indicates required fields

Reliability Engineering Services

- CNC Machine Monitoring

- CNC Machine Monitoring System

- Condition Monitoring Class Enrollment

- Condition Monitoring Class Schedule

- Condition Monitoring Course Outline

- Condition Monitoring and Predictive Maintenance

- Condition Monitoring Services

- Condition Monitoring Training

- Condition Monitoring Training Quote Request

- Equipment Condition Monitoring

- Lubricant Oil Analysis

- Lubricating Oil Analysis

- Machine Condition Monitoring

- Machine Monitoring Systen

- CMRP Certification Training

- CMRP Course

- CMRP Training

- CMRP Training Courses

- Failure Analysis Company

- Failure Analysis Training

- Failure Analysis Training Class

- Failure Analysis Training Class Enrollment

- Failure Analysis Training Class Schedule

- Failure Analysis Training Course

- Failure Analysis Training Instructors

- Failure Analysis Training Quote Request

- High Reliability Training

- Level 1 Thermography Certification Training

- Level 1 Thermal Imaging Training

- Level 1 Thermal Infrared Thermography Certification

- Level 2 Thermography Training

- Maintenance and Reliability Training

- Maintenance and Reliability Training Courses

- Reliability Engineer Training

- Reliability Engineering Training Courses

- Thermography Training Courses

- Vibration Analysis Class

- Vibration Analysis Course

- Certified Maintenance and Reliability Professional Training

- CMRP Certification Course

- Failure Elimination

- High Reliability Organization Training

- Maintenance and Reliability Engineering Courses

- Predictive Maintenance

- Preventive Maintenance

- Reliability Centered Maintenance

- Reliability Certification Courses

- Reliability Consultant

- Reliability Development

- Reliability Engineering Courses

- Reliability Engineering Training

- Workforce Development

- Acoustic Vibration Monitoring

- Bearing Vibration Monitoring

- Blower Wheel Balancing

- Compressed Air Leak Detection

- Compressed Air Leak Detection Survey

- Compressed Air Leak Survey

- Compressed Air Leak Surveys

- Dynamic Rotor Balancing

- Electric Motor Circuit Analysis

- Electric Motor Vibration Analysis

- Electric Motor Testing

- Fan Vibration Testing

- Floor Vibration Testing

- Gas Leak Survey

- Gas Line Leak Test

- Industrial Fan Balancing

- Industrial Predictive Maintenance

- Industrial Vibration Analysis

- Infrared Thermography Inspection

- Infrared Thermography Inspection Services

- IR Thermography

- Laser Alignment Services

- Machine Predictive Maintenance

- Machine Shaft Failure Analysis

- Machine Vibration Monitoring

- Modal Analysis Testing

- Modal Analysis Vibration

- Modal Response Spectrum Analysis

- Motion Amplification

- Motion Amplification Analysis

- Motion Amplification Services

- Motion Amplification Vibration Analysis

- Motor Circuit Analysis

- Motor Circuit Evaluation

- Motor Condition Monitoring

- Motor Current Predictive Maintenance

- Motor Testing

- Motor Vibration Analysis

- ODS Testing

- Offline Motor Testing

- On-Site Vibrational Analysis

- Operational Deflection Shape Analysis

- Optical Gas Imaging

- (OGI) Optical Gas Imaging

- Passive Ultrasonic Listening

- Pump Vibration Testing

- Predictive Asset Maintenance

- Predictive Maintenance Companies

- Predictive Maintenance Consulting

- Predictive Maintenance Program

- Predictive Maintenance Services

- Predictive Maintenance Service

- Predictive Maintenance Solutions

- Predictive Maintenance Vibration Analysis

- Reliability Testing Methods

- Rotating Equipment Monitoring

- Rotating Equipment Condition Monitoring

- Rotating Equipment Vibration Analysis

- SF6 Gas Analysis

- Thermal Imaging Electrical Inspections

- Thermal Imaging Inspection

- Thermographic Testing

- Thermography Testing

- Ultrasound Leak Detection

- Ultrasound Leak Detection Services

- Ultrasonic Leak Testing

- Ultrasonic Valve Leak Detection

- Vibration-Based Condition Monitoring

- Vibration Monitoring Companies

- Vibration Monitoring Services