- Home

- Services/IndustriesServicesindustries

- About Us

- LocationsStatesAccordion ContentAccordion ContentAccordion ContentAccordion Content

- Job Openings

- Quick Links

- ATS Family

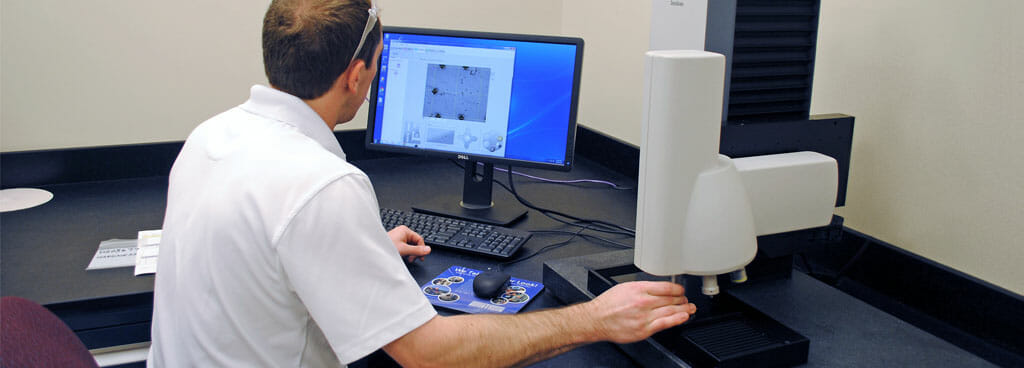

Weld Hardness Testing

Applied Technical Services provides weld hardness testing to a plethora of industry standards such as ASME, API, AWS, MIL-STD, NAVSEA, PED/EN, and AMS. Our weld testing laboratory houses cutting-edge technology to provide clients with unparalleled service. Our experts can perform testing for failure prevention, quality control, and mechanical testing while evaluating weld hardness.

How Does Hardness Testing Work?

The weld testing laboratory at Applied Technical Services utilizes a wide range of hardness testing methods to conduct weld hardness tests. Each hardness test varies by method; however, the procedures all remain relatively similar. A weld hardness test is performed by mechanically pressing a specifically dimensioned object, known as an indenter, onto the weld. Hardness is then determined by measuring the penetration or size of the impression left by the indenter. ATS experts have the ability to conduct Brinell, Barcol, Webster, Rockwell, Vickers, Knoop, and Leeb hardness testing methods as necessary to the project scope. All weld hardness tests performed at ATS follow the below industry standards:

- ASTM A956

- ASTM E18

- ASTM E10

- ASTM E92

- ASTM E384

- ASTM D2583

- ASTM A370

- ASTM B647

- EN 1043-2

- EN 1043-1

- EN 6507-2

- EN 10002

- ISO 9015-2

- ISO 6505-1

ATS Weld Testing Capabilities

Applied Technical Services offers a litany of weld testing and analysis options outside of weld hardness testing. Our team of welding inspection experts is certified by AWS (the American Welding Society) to provide professional analysis. We offer non-destructive weld analyses such as:

Our weld testing laboratory can also provide additional analysis capabilities to analyze a weld’s integrity. Some of these methods are:

- Chemical analysis

- Nick breaks

- Ferrite testing

- Failure analysis

- Macro etching

- Corrosion testing

Quality Assurance

For more than 50 years, Applied Technical Services has been a global leader in inspection, consulting, and testing. With our quality management program, certified to ISO 9001, we strive to provide clients with unparalleled service. Our team can handle all your weld hardness testing needs. Contact ATS today to get in touch with an expert.

Request Form

"*" indicates required fields

Weld Testing Links

- 1G Weld Test

- 2F Weld Test

- 2G Weld Testing

- 3G MIG Welding Test

- 4G Welding Certification

- 6G Welding Certification

- ASME Sect IX Testing

- AWS D1.1 Testing

- AWS D1.2 Testing

- AWS D17.1 Testing

- Certified Welding Inspectors

- Cut and Etch Weld Testing

- Destructive Weld Testing

- Fillet Weld Break Testing

- Fillet Weld Fracture Test

- Fillet Weld Test

- Fillet Weld Testing

- Macro Etch Testing

- Macro Etch Weld Test

- Macro Etch Weld Testing

- Pipeline Inspection Companies

- Pipe Weld Testing

- SMAW Welding Certification

- Spot Weld Testing

- Structural Steel Welding Certification

- Stick Welding Certification

- Visual Weld Testing

- Weld Engineering Company

- Weld Analysis

- Weld Bend Testing

- Weld Break Testing

- Weld Hardness Testing

- Weld Inspections

- Weld Inspections Services

- Weld Joint Testing

- Weld Notch Toughness Testing

- Weld Procedure Qualifications

- Weld Tensile Testing

- Weld Testing

- Weld Testing Services

- Weld Qualification Testing

- Welder Certification

- Welder Qualification

- Welding Certification

- Welding Certification Test

- Welding Engineering

- Welding Inspector

- Welding Test Coupon

- Welding Testing Lab

- Weld Testing Services

- WPS Qualified Welding Procedure

- WPS Welder Qualifications